Rotary Dryers

Biomass Dryer

Biomass Dryer Animal Feed Dryer

Animal Feed Dryer Industrial Dryer

Industrial DryerMineral Dryer

Explore advanced mineral dryers for efficient and reliable drying processes. Boost productivity with durable solutions tailored for mining operations.

Wood Chips Dryer

Optimize your drying process with our dependable wood chips dryers. Perfect for large-scale operations seeking consistent, high-quality drying results.

Triple Pass Rotary Drum Dryer

Maximize your drying efficiency with our reliable triple pass rotary drum dryers. Engineered for consistent performance and reduced energy consumption in industrial settings.

Sand Dryer

Explore our durable sand dryers engineered for superior drying performance. Ideal for large-scale operations seeking energy-efficient drying solutions.

Sawdust Dryer

Enhance your drying process with our reliable sawdust dryers. Ideal for industries seeking consistent, high-quality drying with reduced energy consumption.

Clay Dryer

Find industrial-grade clay dryers for reliable performance and durability. Ideal for various industries seeking efficient drying solutions. View our selection.

Alfalfa Dryer

Reduce costs with energy-saving alfalfa dryers. Perfect for maximizing yield and ensuring quality in your forage processing.

Vinasse Dryer

Cut operational costs with our energy-saving vinasse dryers. Perfect for distilleries focused on efficient byproduct processing and sustainability.

Cassava Residue Dryer

Invest in advanced cassava residue dryers for consistent, reliable performance. Perfect for improving byproduct utilization and processing.

Bean Dregs Dryer

Reduce costs with our energy-saving bean dregs dryers. Ideal for industries focusing on efficient and sustainable byproduct processing.

Bentonite Dryer

Choose reliable bentonite dryer solutions to maximize efficiency in mineral processing. Enhance productivity and product quality.

Pomace Dryer

Invest in advanced pomace dryers for reliable and consistent drying results. Perfect for optimizing byproduct use and enhancing farm efficiency.

Yeast Dryer

Brewer’s yeast dryer is a kind of drum dryer that uses steam to heat materials and vaporize water through indirect conduction heating. The core technology of the dryer is temperature control to avoid killing the beneficial ingredients in th...

Spent Grain Dryer

Brewer’s spent grain (BSG) is the by-product of the beer production process. It contents a large amount of nutrients such as undecomposed crude protein, crude fiber, crude fat and other nutrients. The dried distiller’s grains are good raw m...

Palm Fiber Dryer

Palm fiber is the waste material from the production of palm oil. With the rise of the biomass energy industry, the application range of palm fiber has been expanded, solving the environmental pollution caused by palm thread. After bei...

Sugarcane Dryer

Sugarcane is one of the main sources of sugar. Sugarcane residues from sugar processing are mainly used to make paper or as fuel. The first step in reusing sugarcane is to remove moisture. Treatment and reuse dryers are mainly used for the ...

Gypsum Rotary Dryer

The gypsum dryer is a drying equipment used to remove water from desulfurized gypsum. The main application of desulfurized gypsum is to use it as cement retarder after drying. The gypsum rotary dryer adopts downstream drying method. The hot...

Sludge Dryer

Zoneding Company conducted technical research on sludge treatment, created a new generation of sludge rotary drum drying system that can reduce product moisture to less than 25%, with mature technology and easy operation and maintenance. ...

Coal Dryer

Zoneding’s coal dryer is designed to handle high-humidity coal, suitable for various coal particles. It efficiently smashes and dries coal, making it a versatile source for power plants and industrial raw materials, with applications in con...

loading...

已经是到最后一篇内容了!

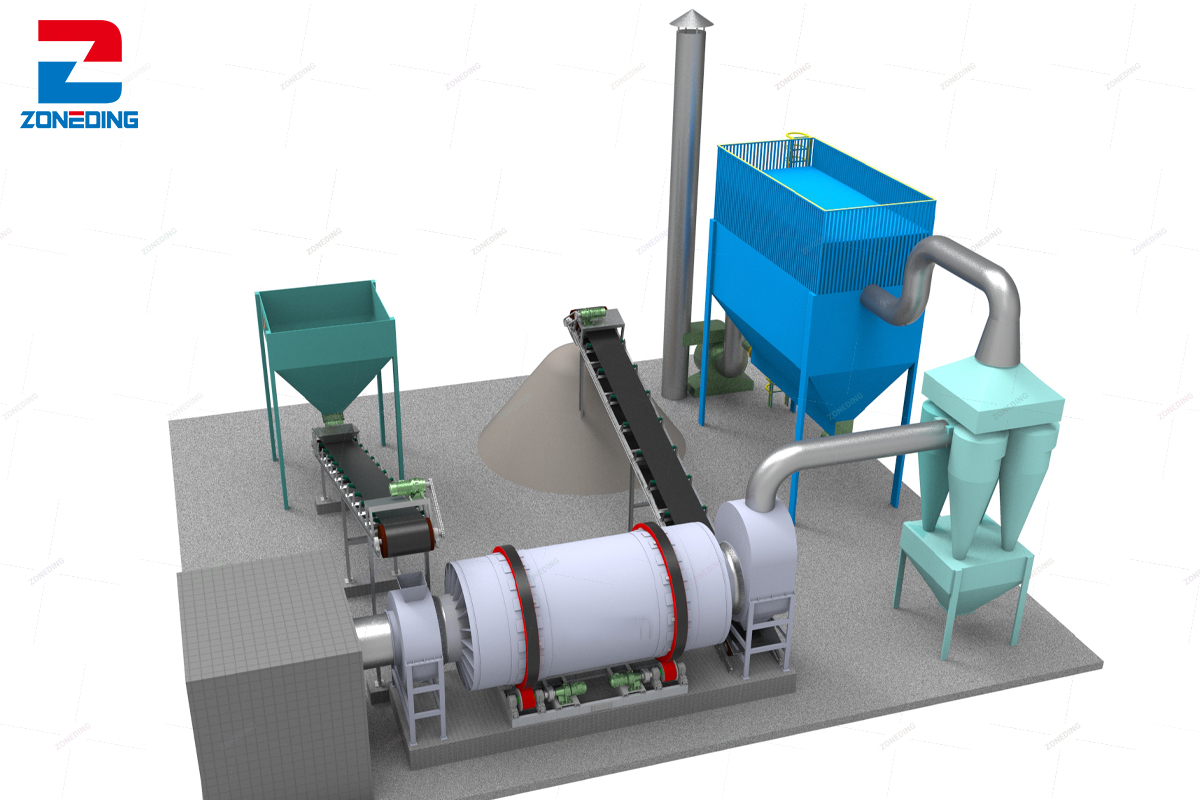

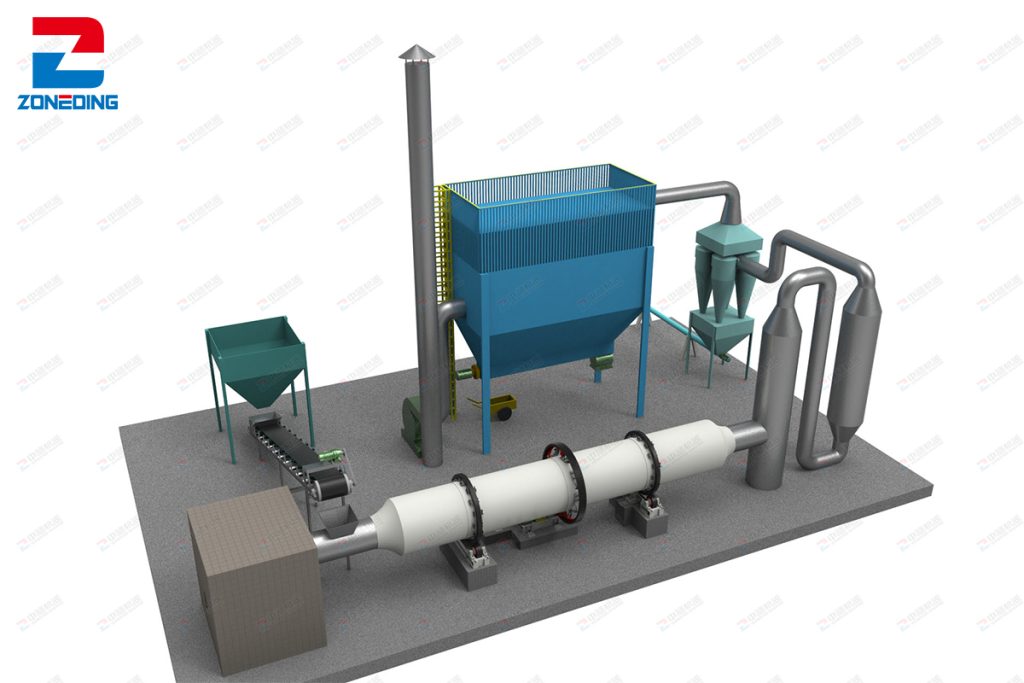

Drying process

We tailor-make various drying material solutions for each customer

Sand drying process

The drying production line is a complete set of equipment for heat drying and screening sand or other bulk materials. It consists of the following parts: wet sand hopper, belt feeder, belt conveyor, burning chamber, rotary dryer (three-cylinder dryer, single-cylinder dryer), cyclone, pulse dust collector, draught fan, vibrating screen, and electronic control system.

The sand is fed into the wet sand hopper by the loader, and be conveyed to the inlet of the dryer through the belt feeder and conveyor, and then enters the rotary dryer. The burner provides the drying heat source, and the dried sand is sent to the vibrating screen by the belt conveyor for screening (usually the mesh size is 0.63, 1.2 and 2.0mm, the specific mesh size is selected and determined according to actual needs). During the drying process, the draught fan, cyclone, pulse dust collector and pipeline constitute the dust removal system of the production line, and the whole line is clean and tidy!

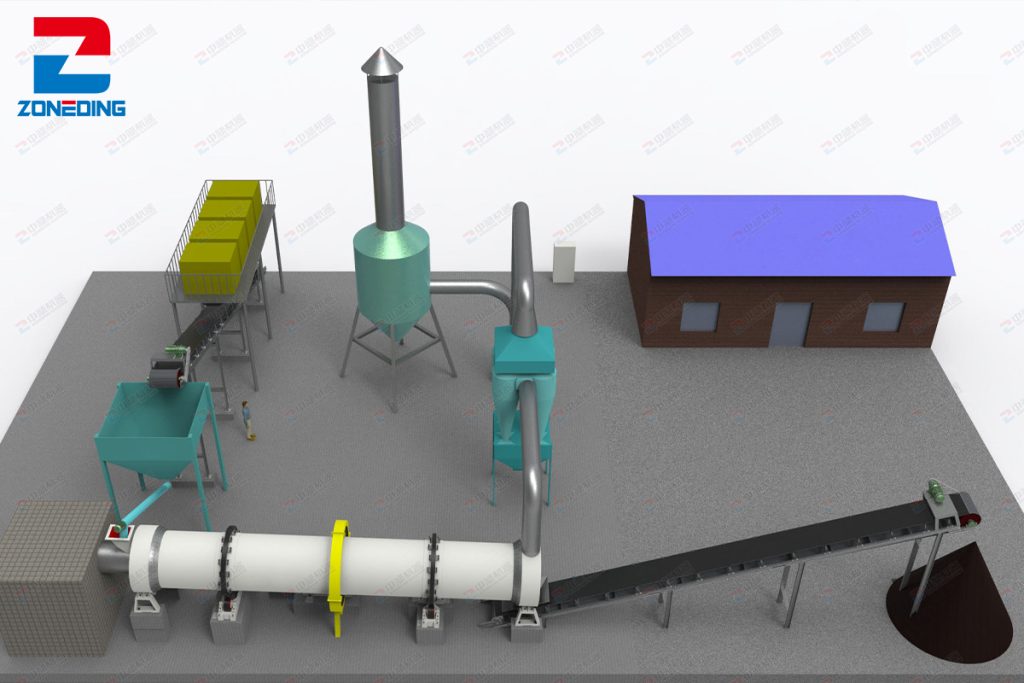

Coal drying process

The dried raw coal is first dispersed by a special feeding distributor and then transported to the feeder through the belt feeder. Then the feeding carbon transports the wet solution to the raw coal dryer drum. When the reader is tipped over evenly distributed in the dry drum, the solution is evenly dispersed and fully in contact with the hot air to achieve the purpose of heat transfer and dryness. The dried coal pulp comes out of the end of the drum, the finished products are discharged by the belt discharger to complete the drying process.

Sawdust drying process

The wood chips dryer is mainly composed of silo, feeding conveyor belt, hot air system, rotary dryer, discharging conveyor belt, cyclone dust collector, induced draft fan, wet dust collector, etc. The hot air system adopts new environmentally friendly biomass thermal equipment to ensure sufficient heat and good heat transfer effect. The lifting plates inside the dryer barrel are arranged in a spiral pattern to repeatedly lift and spread materials, resulting in extremely high heat exchange efficiency.

Rotary Dryer Projects

Durable Machinery

Durable Machinery