Search the whole station liberty-fse

QMJ2-40 Portable Ash Brick Machine

Capacity:2 pieces per mould; 1440 pieces per 8 hours

Power Type: Diesel Engine/Electric Motor

Workers Needed: 1-2 persons

Forming Cycle:40-45 seconds

Moulding Method: Mechanical Vibration Molding

Brick Size: Different sizes and shapes including 4inch,6inch,8inch hollow blocks, solid bricks.

Introduction:

QMJ2-40 is an outstanding piece of portable brick machinery designed for maximum flexibility and efficiency. As our smallest model, this mobile brick machine is the perfect solution for businesses with limited space. Its ability to process fly ash makes it an environmentally conscious choice. The QMJ2-40’s portable nature ensures you can take your production wherever it’s needed most, making it a top-tier investment in the fly ash brick machinery market.

QMJ4-30 Mobile Fly Ash Brick Making Machine

Capacity: 4-6 pieces per mould; 6000-9000 pieces per 8 hours

Power Type: Electric Type

Workers Needed: 2-3 persons

Forming Cycle: 30-35 Seconds

Moulding Method: Vibration Moulding and Hydraulic Pressure

Brick Size: Hollow blocks, Solid bricks, Kerbstone, concrete blocks, fly ash bricks, cinder bricks etc..

Introduction:

For businesses seeking a top-tier mobile hydraulic bricks machine, the QMJ4-30 offers a combination of power, mobility, and cost-efficiency. Its advanced hydraulic system ensures every block meets high-density standards, making it a reliable choice for any construction project. Furthermore, its capability as an ash bricks machine allows for the use of sustainable materials like fly ash, catering to the growing demand for eco-friendly building solutions. The true advantage of this mobile hydraulic bricks machine is its pallet-free operation, which provides significant savings.

QMJ10-25 Mobile Automatic Bricks Machine

Capacity:10 pieces per mould; 11520 pieces per 8 hours

Power Type: Electric Type

Forming Cycle:25-30 Seconds

Moulding Method: Vibration Moulding and Hydraulic Pressure

Brick Size: 400*200*200mm hollow blocks, 400*150*200mm solid bricks,400*100*200mm hollow bricks, paver bricks, kerstone.

Introduction:

QMJ10-25 is suitable for businesses demanding a high-performance brick production machine. Its core strength lies in being a state-of-the-art mobile hydraulic bricks machine, using powerful hydraulics to create exceptionally strong blocks while offering the flexibility of a mobile platform. As a versatile concrete bricks machine, it processes various raw materials, including fly ash and cement, allowing you to diversify your product line easily. Investing in the QMJ10-25 means investing in a reliable, high-capacity, and flexible brick production machine built for the future.

DM4-40 Manual Ash Bricks Machine

Capacity: 4-14 pieces per mould;2200-6800 pieces per 8 hours

Power Type: Electric Motor

Workers Needed: 2-3 persons

Forming Cycle: 40-45 seconds

Brick Size: Different sizes and shapes including 400*200*200mm;400*150*200mm;400*100*200mm hollow blocks, solid bricks, I Shape,H Shape,Z Shape paver & curbstone.

Components: 350Pan Mixer+DM4-40 block machine with 1 set block mould

Introduction:

The DM4-40 is a top-performing small brick machine specifically engineered for those seeking an affordable bricks machine and efficient machine to make bricks. Its design as a stationary brick machine ensures a stable and consistent production environment, perfect for a permanent workshop setup. Operation is straightforward, as it functions as a manual bricks machine, which drastically reduces maintenance costs and simplifies training for new operators.

QT4-25 Automatic Machine Line for Brick Making

Capacity: 4-10 pieces per mould; 6000-12000 pieces per 8 hours

Power Type: Electric Motor

Forming Cycle: 25-30 Seconds

Brick Size: Hollow blocks, Solid bricks, Kerbstone, Paver bricks concrete blocks, fly ash bricks, cinder bricks etc..

Components: Belt Conveyor+Concrete Mixer+QT4-25C Block Making Machine +PLC Control System+Spare Parts/Tools+Manual Block-transportingCarts/Push-carts+Block Mould: 400×200×200 mm For Free

Introduction:

The QT4-25C is a highly efficient semi-automatic making bricks machine engineered for medium-sized businesses looking to boost productivity. As a machine that makes bricks using an intelligent PLC control system, it delivers consistent quality and reduces operational errors. Its automated features, including pallet and material handling, offer significant advantages over manual equipment.

QT8-15 Stationary Concrete Brick Block Making Machine Line

Capacity:8-20 pieces per mould; 12000-3000 pieces per day

Power Type:Electric Motor

Forming Cycle: 15-20 Seconds

Brick Size: All blocks in one machine

Introduction:

The QT8-15 is a premier fully automatic block machine engineered for industrial-scale production of high-quality concrete products. As a leading concrete block machine, it integrates a powerful hydraulic block machine system with advanced PLC controls to ensure maximum efficiency and consistent output. It excels as a hollow block machine and can be adapted to produce a wide variety of pavers and solid bricks by simply changing the mold. For businesses seeking a reliable, high capacity block machine that minimizes labor and maximizes profitability, the QT8-15 offers the perfect combination of power, automation, and versatility.

Looking for a sustainable and profitable venture in the construction industry? Consider the potential of fly ash bricks. A Fly Ash Brick Machine offers a viable and eco-friendly alternative to traditional clay bricks, producing durable building materials from industrial waste. But are they really profitable? Let’s dig deeper into the world of fly ash bricks and the machines that make them.

Last Updated: 2025.5 | Estimated Read Time: 12 minutes

Fly Ash Bricks, or Flyash Bricks, are building bricks made primarily from fly ash, a byproduct of coal combustion in power plants, offering a sustainable alternative to traditional clay bricks. Fly ash bricks represent a sustainable approach to construction. Flyash bricks use fly ash, a waste product from coal-fired power plants, as a primary ingredient. They are a greener alternative to traditional clay bricks, reducing the environmental impact of brick manufacturing. Ash bricks offer good strength, uniform size, and lower water absorption compared to clay bricks.

Types of Fly Ash Bricks vary based on the production method and composition, including cement-stabilized, lime-stabilized, and autoclaved bricks.

The composition and manufacturing process determines the type of fly ash bricks:

Ash Bricks are suitable for various construction applications, including load-bearing walls, partition walls, and paving.

Ash bricks offer a versatile building material for a range of construction projects:

Fly ash bricks are just one option in the brick world. How do they stack up against the competition? Compared to concrete blocks and clay bricks, Fly Ash Bricks are lighter, more eco-friendly, and often offer better thermal insulation. However, their strength and durability can vary depending on the manufacturing process.

Here’s a comparison of fly ash bricks, concrete blocks, and clay bricks:

| Feature | Fly Ash Bricks | Concrete Blocks | Clay Bricks |

|---|---|---|---|

| Raw Materials | Fly ash, cement/lime, sand | Cement, aggregates (sand, gravel) | Clay |

| Weight | Lighter than clay bricks and concrete blocks | Heavier than fly ash bricks | Heavier than fly ash bricks |

| Environmental Impact | More eco-friendly due to the use of waste material and reduced energy consumption | Less eco-friendly due to the use of cement and aggregates | Environmentally damaging due to clay extraction and high energy consumption |

| Strength | Can be comparable to or higher than clay bricks, especially autoclaved bricks | High strength | Varies depending on the quality of clay and the firing process |

| Thermal Insulation | Better thermal insulation than clay bricks and concrete blocks | Lower thermal insulation | Lower thermal insulation |

| Water Absorption | Lower water absorption than clay bricks | Higher water absorption | Higher water absorption |

Properly manufactured fly ash bricks can be just as durable, or even more durable than traditional clay or concrete bricks.

Choosing Fly Ash Bricks offers numerous benefits, including environmental sustainability, cost-effectiveness, improved building performance, and reduced construction time.

Fly ash bricks offer several compelling advantages:

The raw materials for Fly Ash Brick Production typically include fly ash, cement or lime, sand, and water. The specific proportions vary depending on the desired brick properties.

The main ingredients for fly ash brick production are:

The water-to-binder ratio (W/B) is even more critical with fly ash than with ordinary Portland cement.

An Ash Brick Machine, also known as a Fly Ash Brick Making Machine, is a machine designed to produce fly ash bricks efficiently and consistently. These machines come in various sizes and automation levels.

An ash brick machine is a specialized piece of equipment designed for brick block making. It automates the process of mixing, molding, and ejecting fly ash bricks. A machine to make bricks offers a cost-effective way to mass produce a greener alternative to clay bricks. DURABLE MACHINE provides all kinds of ash brick making machine, which can meet your requirements well.

Key components of a Fly Ash Brick Making Machine include a mixer, a mold, a hydraulic system, and a control panel.

Fly ash brick making machines typically consist of these components:

DURABLE MACHINE uses high-strength steel as material, takes wire-cut technology, and PLC control system from Siemens. We can offer durable brick machine for you.

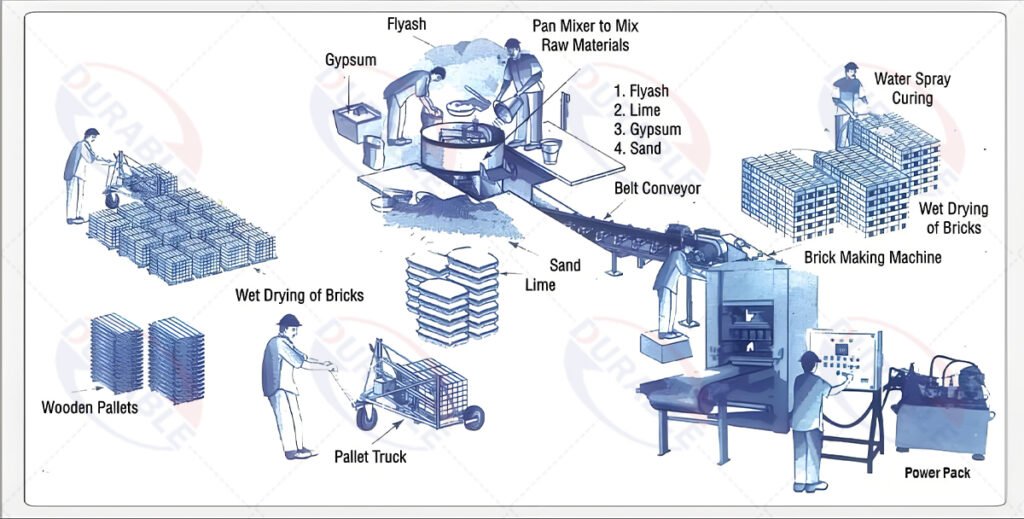

The Manufacturing Process for fly ash bricks involves mixing raw materials, molding the mixture, curing the bricks, and quality control.

The process to make ash bricks typically involves these steps:

DRUABLE MACHINE offers a range of Fly Ash Brick Making Machines, from manual to fully automatic, with varying capacities to suit different production needs.

DRUABLE MACHINE offers various options for machine for brick making:

DURABLE MACHINE offers complete block moulding machine lines with integrated components for seamless operation.

The Brick Manufacturing Machine Price varies widely depending on the type and capacity of the machine, ranging from a few thousand dollars for a manual machine to hundreds of thousands for a fully automatic one.

DURABLE MACHINE price:

The brick manufacturing machine price depends on several factors:

Before starting a brick business, you should conduct market research, secure funding, obtain necessary permits and licenses, and source reliable suppliers for raw materials and equipment.

Starting a bricks made machine business requires careful planning:

Selecting the right Fly Ash Brick Machine involves considering your production capacity, budget, desired automation level, and the availability of skilled labor.

Choosing the right bricks machine requires careful evaluation:

To find a reliable supplier for your Fly Ash Brick Machine, research online, check references, visit factories, and compare prices and warranties.

Finding a reliable supplier for your machine that makes bricks is crucial:

Important tips for Fly Ash Brick Manufacturing include using high-quality raw materials, maintaining the correct water-to-binder ratio, proper curing, and regular quality control testing.

To produce high-quality fly ash bricks, keep these tips in mind:

DRUABLE Bricks Machines are known for their robust construction, efficient design, user-friendly operation, and excellent after-sales service. Our Machine for Brick Making are the product of expertise.

DRUABLE bricks machine offers several advantages:

The purchasing process from DRUABLE involves an inquiry, quotation, order confirmation, payment, production, delivery, installation, and commissioning.

The purchasing process at DRUABLE is streamlined:

Maintenance requirements for a Fly Ash Brick Machine include regular lubrication, cleaning, inspection, and timely replacement of worn parts.

Proper maintenance is essential for extending the life of your making bricks machine: