Hammer Mill Crusher

A Hammer Mill Crusher is a high-speed size reduction machine that uses the principle of impact to shatter or pulverize a wide variety of materials. It is one of the most versatile and common types of crushers used across many industries.

Its primary function is to take medium-hard, brittle, or fibrous materials and reduce them to a fine, uniform powder or granular consistency.

Hammer mills are extremely versatile and are used in numerous industries:

Agriculture,Industrial,Recycling,Forestry & Wood Processing,Food Processing.

At Durable, we have specialized in manufacturing industrial processing equipment since 2001. We know that when you are researching a Hammer Mill Crusher, you are looking for a machine to achieve a very specific particle size. Your success depends on more than just horsepower. It depends on understanding the internal mechanics of the machine. This guide provides the technical details you need. We will explain how to control the output, prevent common problems like screen blockage, and choose the right design for your specific material, whether it is for animal feed or biomass.

Table of Contents

- What is a Hammer Mill Crusher?

- What materials and industries use a Hammer Mill Crusher?

- How do you change the output fineness (Mesh)?

- How often do hammers and screens need replacing, and how do you calculate the cost?

- How can you prevent screen blockage with high-moisture or high-fiber materials?

- Water-Drop vs. Common Hammer Mill: What is the difference in efficiency?

- What key performance indicators should I check besides output?

- FAQs

What is a Hammer Mill Crusher?

A hammer mill crusher is a type of industrial crusher used to shred or crush material into smaller pieces. It does not cut or use compression. Instead, its principle is high-speed impact. Inside a grinding chamber, a rotor spins at very high RPM (typically 1,500 to 3,600 RPM). Attached to this rotor are multiple swinging steel “hammers.” As the rotor spins, these hammers are thrown outwards by centrifugal force. Material is fed into the chamber, where it is repeatedly struck by these hammers. The material shatters upon impact and is thrown against the chamber’s inner walls or specialized breaker plates, causing it to break further. This process continues until the particles are small enough to pass through a perforated screen that covers the discharge opening. In short, it is a simple but brutal machine designed for high-volume size reduction.

What materials and industries use a Hammer Mill Crusher?

A hammer mill crusher is one of the most versatile pieces of size reduction equipment available. Its simple and robust design allows it to process a vast range of materials across many industries. The key requirement is that the material must be brittle enough to shatter on impact.

Primary Applications:

- Animal Feed Production: This is one of the largest uses. Hammer mills are essential for grinding corn, soybeans, wheat, and other grains into fine meal for Feed Pellet Machines. The uniform fine grind improves digestibility and mixing.

- Biomass and Wood Processing: They are widely used to create wood powder from sawdust, wood chips, and shavings. This powder is a key raw material for making wood pellets or for use in engineered wood products. They also grind agricultural residues like straw, corn stover, and rice husks.

- Minerals and Chemicals: Hammer mills are used for grinding softer, non-abrasive minerals like coal, limestone, gypsum, and various chemical compounds.

- Food Processing: They are used to grind everything from spices and grains to sugar and dried herbs.

How do you change the output fineness (Mesh)?

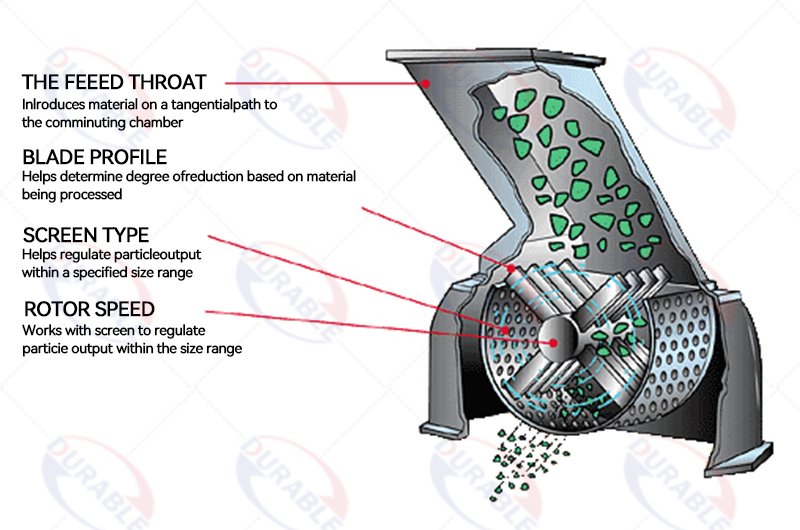

Controlling the final particle size, often measured in mesh, is the primary goal of using a hammer mill. This is achieved through a combination of several key adjustments, not just one.

The most direct and common method is by changing the screen. The screen is a perforated metal sheet that lines the bottom half of the grinding chamber. The size of the holes in this screen determines the maximum size of the particles that can exit the machine. To get a finer powder (a higher mesh number), you install a screen with smaller holes. To get a coarser product, you use a screen with larger holes. Screens are available in a wide range of hole sizes, from less than 1 mm to over 25 mm.

However, for truly precise control, you must also consider the tip-to-screen clearance. This is the physical distance between the tips of the spinning hammers and the inner surface of the screen.

- A smaller clearance forces material to be ground more intensely against the screen, resulting in a finer product.

- A larger clearance allows material to pass through more easily, resulting in a coarser product but higher throughput.

Adjusting this clearance is a critical step for optimizing the crusher for a specific material and desired output.

How often do hammers and screens need replacing, and how do you calculate the cost?

Hammers and screens are the primary consumable parts, and their replacement is a major component of your operational cost. Their lifespan depends entirely on the abrasiveness of the material you are grinding and the quality of the steel they are made from.

| Hammer Material | Strengths | Weaknesses | Best For |

|---|---|---|---|

| High-Manganese Steel | Very tough, resists fracturing | Wears down faster with abrasive material | Grinding chunky wood or materials with potential for metal contamination. |

| High-Chrome Cast Iron | Extremely hard and wear-resistant | Brittle, can shatter with high impact | Abrasive materials like coal, minerals, and high-silica biomass. |

| Tungsten Carbide Tipped | The most wear-resistant option | Highest cost, very brittle | Highly abrasive, consistent feedstock like clean sawdust or certain chemicals. |

To calculate your operational cost, you need to track how many tons of material you can process before a set of hammers or a screen wears out.

A key feature on advanced industrial hammer mills that significantly lowers this cost is a reversible rotor. These machines have a symmetrical grinding chamber and a motor that can run in both directions. By switching the rotation direction daily or weekly, you can use both leading edges of the hammers. This ensures even wear and can nearly double the lifespan of each set of hammers, cutting your replacement costs and downtime in half.

How can you prevent screen blockage with high-moisture or high-fiber materials?

Screen blockage, or “blinding,” is the most common problem when grinding materials that are fibrous, oily, or have slightly elevated moisture content. It happens when fine, sticky particles clog the holes in the screen, preventing any further material from passing through. This causes a rapid drop in output, an increase in motor temperature, and can lead to a complete jam.

The most effective solution to this problem is an air-swept system, also known as a pneumatic conveyance system. This is a standard feature on all high-performance industrial hammer mills. Here is how it works: an industrial fan (blower) is connected to the discharge of the hammer mill. This fan creates a strong, continuous negative pressure inside the grinding chamber. This airflow literally pulls the correctly sized particles through the screen holes the instant they are created. This has two major benefits:

- It prevents blockage: The fine particles do not have a chance to linger and stick to the screen.

- It increases efficiency: By immediately removing finished material, it prevents the hammers from wasting energy by over-grinding particles that are already small enough. This “air-assist” also helps to keep the grinding chamber cool, which is critical for heat-sensitive materials.

Water-Drop vs. Common Hammer Mill: What is the difference in efficiency?

The “water-drop” hammer mill is a more modern and efficient evolution of the classic rectangular hammer mill design. Its name comes from the shape of its grinding chamber, which resembles a water droplet in cross-section. This specific shape provides significant performance advantages.

In a common rectangular hammer mill, a “cushion” of circulating material can form in the upper corners of the chamber. New material entering the mill hits this cushion instead of being struck directly by the hammers, which wastes energy. The water-drop design eliminates these corners. Its curved top forces all material directly into the path of the spinning hammers for a primary, high-impact strike. It also creates a smoother path for the material to travel towards the screen for a secondary grinding action.

The result of this optimized design is a measurable increase in efficiency. A water-drop hammer mill can achieve the same output as a common hammer mill while consuming 15-20% less energy. Or, for the same amount of power, it can deliver a higher throughput. For any industrial application where energy costs and output are critical, the water-drop design is the superior choice.

What key performance indicators should I check besides output?

When selecting a hammer mill, looking beyond the advertised tons per hour will help you choose a machine that is truly efficient and durable. Here are the critical technical details to investigate:

1.The Role of the Breaker Plates: Inside the chamber, most of the initial, heavy-duty grinding is not done by the hammers hitting the screen. It is done when the hammers smash the material against thick, hardened steel plates called breaker plates that line the upper part of the chamber. These plates are designed to take the primary impact. If these plates are worn, overall efficiency will drop significantly, even if the hammers and screen are new, because the first and most powerful impact is weakened.

2.Hammer Arrangement on the Rotor: More hammers is not always better. The arrangement and density of the hammers on the rotor are carefully engineered. There must be enough space between the hammers to allow material to be properly picked up and accelerated. If the hammers are too densely packed, they create a “fanning” effect that prevents material from entering the hammer path effectively. This leads to a situation where the motor is running at full power, but the actual grinding work being done is very low.

3.Manufacturing quality and rotor balance: A hammer mill is a high-vibration machine. Look for a heavy, welded steel body that can withstand long-term operational stress.

FAQs

Q1: Can a hammer mill crusher process wet material?

A: No. Hammer mill crushers are designed for dry grinding, typically with material moisture below 15%. Wet or sticky material will not shatter on impact; instead, it will smear and quickly clog the screen, halting production.

Q2: My hammer mill crusher motor is running, but the output is very low. What is the problem?

A: The most likely cause is a clogged screen. Check for material buildup. Other causes include worn-out hammers that are no longer effective, or the tip-to-screen clearance being too large for the desired fineness.

Q3: How fine can a hammer mill crusher grind?

A: With the right combination of a fine-mesh screen, high rotor speed, and a tight tip-to-screen clearance, a hammer mill can grind materials down to powders of 100-200 mesh. However, at these fine levels, output capacity is significantly reduced.

Q4: What is the main difference between a hammer mill and a jaw crusher?

A: A hammer mill uses high-speed impact to shatter material into powder and is used for secondary or fine grinding. A Crusher, like a jaw or cone crusher, uses immense compressive force to break large rocks into smaller pieces and is used for primary, coarse crushing.

Q5: Is a hammer mill crusher very loud?

A: Yes, hammer mill crushers are inherently loud machines due to the high-speed impact process. For industrial installations, they are often placed in separate rooms or soundproof enclosures to comply with workplace safety regulations.

Durable Machinery

Durable Machinery