How to Choose a Concrete Mixer: An Expert Guide

Choosing a concrete mixer is not just buying a machine; it is a critical investment that defines the quality of your work and the profitability of your business. With over two decades at Durable, I have seen clients make brilliant decisions that propelled their companies forward, and I have also seen costly mistakes that could have been easily avoided. The mixer is the heart of your operation. Get it right, and you have a foundation for success.

This guide is my personal checklist, designed to walk you through the decision-making process exactly as I would with a client. We will move beyond simple product lists and focus on what truly matters: matching the right technology to your specific application.

Table of Contents

- What concrete type will you produce?

- Which mixer type is best for your plant?

- Stationary Plant Mixer vs. Self-Loading Mobile Mixer: How to Decide?

- Beyond Price: Key Factors Affecting Long-Term Costs

- How to Evaluate a Concrete Mixer Manufacturer?

- Common Questions About Concrete Mixers

- Summary and Recommendations

What concrete type will you produce?

This is the most important question. The type of concrete you need to produce dictates the type of mixer you must have. A mixer designed for simple mortar will fail spectacularly if you try to produce high-performance concrete with it. Thinking about your end product first is the key to making the right choice.

Different concrete mixes have vastly different demands on the mixing action:

- Standard Concrete (e.g., C20/25 for general construction): This is the most common type. It requires good, consistent mixing but is relatively forgiving.

- High-Performance Concrete (HPC) / Self-Compacting Concrete (SCC): These are advanced, engineered mixes with low water content, special admixtures, and sometimes fibers. They require an intense, high-energy mixing action to ensure every particle is perfectly coated and the mix is completely uniform.

- Precast & Architectural Concrete: For these products, consistency and finish are everything. The mixer must produce batches with identical color and texture, time after time. This requires a thorough but non-aggressive mixing action.

- Mortars and Plasters: These mixes require simple blending to achieve workability. They do not need the high-energy mixing of structural concrete.

Which mixer type is best for your plant?

Once you know your concrete type, you can choose the right mixing technology. There are two fundamental principles: “gravity mixing” (like a simple drum) and “compulsory mixing” (where paddles force the material to mix). For any professional application, compulsory mixing is superior.

Here is how the three main mixer types stack up:

| Mixer Type | Mixing Principle | Best For | Your Key Benefit |

|---|---|---|---|

| Drum Mixer | Gravity (materials tumble and fall) | Small jobs, mortars, non-structural concrete. | Low initial cost, simple to operate and maintain. |

| Twin-Shaft Mixer | Compulsory (intense, turbulent, forced mixing) | High-volume ready-mix, standard to high-strength concrete, RCC. | Extremely fast mixing (30-60s), high output, very efficient. |

| Planetary Mixer | Compulsory (thorough, sweeping, “planetary” motion) | Precast, colored concrete, SCC, fiber concrete, high-value products. | Unmatched homogeneity, perfect for sensitive and dry mixes. |

Expert Takeaway:

- For high-volume production of standard to high-strength concrete, like in a ready-mix concrete batching plant, the Twin-Shaft Mixer is the undisputed king. Its speed and efficiency deliver the lowest cost per cubic meter.

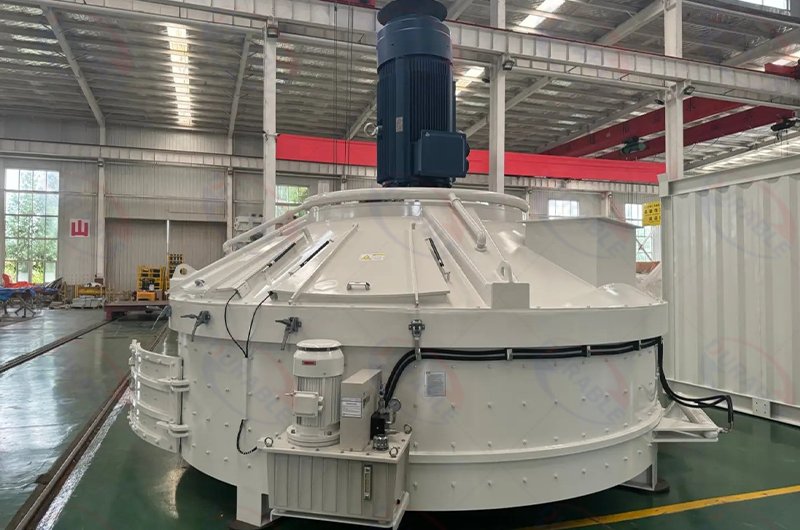

- For producing high-value precast elements or architectural concrete, where quality and consistency are paramount, the Planetary Mixer is the professional’s choice. Its mixing action is gentle yet incredibly thorough.

- A Drum Mixer is a useful tool for small-scale work, but it is not suitable for producing engineered, quality-controlled concrete.

Stationary Plant Mixer vs. Self-Loading Mobile Mixer: How to Decide?

This is a strategic choice about your business model. Do you bring the materials to a central plant, or do you bring the plant to the materials?

1. Stationary Mixer (The Factory Heart)

- What it is: A twin-shaft or planetary mixer that serves as the central component of a fixed Concrete Batching Plant.

- Who it’s for: Ready-mix concrete suppliers, large precast factories, and major construction projects with a long duration at a single site.

- Why choose it: It offers the highest production capacity and the lowest cost per cubic meter of concrete when operating at scale. It is the core of a permanent production business.

2. Self-Loading Concrete Mixer (The Plant on Wheels)

- What it is: A revolutionary machine that combines a wheel loader, a batching system, and a mixer on a single chassis. It can load its own aggregates and cement, mix the concrete on the move, and pour it directly where needed.

- Who it’s for: Contractors working on remote projects (wind farms, pipelines), infrastructure with long alignments (rural roads, canals), and any site where setting up a full plant is too costly or impractical.

- Why choose it: It offers unparalleled flexibility and drastically reduces setup time and the need for other equipment. For the right project, the Self-Loading Concrete Mixer provides the lowest total project cost.

Your Decision Checklist:

- Choose a Stationary Plant if: Your business is based in one location and you supply concrete to multiple customers or a single, large, long-term project.

- Choose a Self-Loading Mixer if: Your business involves moving from one project to another, often in areas without easy access to ready-mix concrete.

Beyond Price: Key Factors Affecting Long-Term Costs

The initial purchase price is only part of the story. The Total Cost of Ownership (TCO) is what truly impacts your profitability. A cheap mixer can be the most expensive machine you ever buy due to downtime and high running costs.

Here are the critical factors to investigate:

- Wear Parts Quality: The mixing paddles and liners take a beating. Look for high-quality, wear-resistant materials like high-chromium cast iron. Ask about the expected lifetime and the cost of a replacement set. At Durable, we use advanced alloys to extend the life of these parts by up to 30%.

- Ease of Maintenance: How easy is it to access grease points and change wear parts? Look for features like wide access hatches and automated lubrication systems. Every hour spent on maintenance is an hour you are not producing concrete.

- Energy Efficiency: The motor and gearbox are the biggest power consumers. A high-efficiency design from a reputable brand can save you thousands in electricity costs over the life of the machine.

- Reliability and Downtime: This is the biggest hidden cost. A breakdown during a critical pour can be disastrous. This is where choosing a reputable mixer manufacturer with a proven track record becomes a crucial financial decision.

How to Evaluate a Concrete Mixer Manufacturer?

Your relationship with the manufacturer does not end after the sale. They are your partner for the life of the machine.

Here is how to assess their reliability:

- Experience and Track Record: How long have they been building mixers? Ask for case studies and references from customers in your region or industry.

- Technical Support: Do they have engineers who can provide expert advice? Can they help you with plant layout and integration?

- Spare Parts Availability: How quickly can they supply you with critical wear parts? A machine is worthless if it is waiting for a spare part from halfway around the world. We maintain a global spare parts network to ensure our clients face minimal downtime.

- Manufacturing Quality: Look beyond the paint. Inspect the quality of the welds (we use robotic welding for consistency), the precision of the components, and the brands of key parts like the gearbox and bearings. These details reveal a manufacturer’s commitment to quality.

Common Questions About Concrete Mixers

Q 1: What is the main difference between a twin-shaft and a planetary mixer?

A: A twin-shaft mixer creates an intense, fast, and turbulent mixing action, ideal for high-volume production of most concrete types. A planetary mixer has a more complex, sweeping motion that is incredibly thorough, making it perfect for high-value precast and dry, sensitive mixes where perfect homogeneity is required.

Q 2: Can a self-loading concrete mixer produce high-quality concrete?

Yes, absolutely. Modern self-loading concrete mixers are equipped with precise electronic weighing systems and water flow meters. They can produce quality-controlled, consistent batches of concrete that meet strict specifications, right at the job site.

Q 3: How long do concrete mixer wear parts last?

A: This depends heavily on the type of aggregate being used (e.g., abrasive river gravel vs. softer limestone) and the mixer’s usage. However, high-quality high-chromium cast iron wear parts in a well-maintained mixer should last for 50,000 to 100,000 cubic meters of production.

Q 4: What is the best mixer for a precast concrete factory?

A: For most precast applications, especially those involving complex shapes, colored concrete, or self-compacting concrete, the planetary mixer is the preferred choice due to its superior mixing homogeneity.

Summary and Recommendations

Choosing the right concrete mixer is a strategic decision. It begins with a clear understanding of your end product and production needs.

- First, define your concrete type. This determines the mixing technology you need.

- Second, choose the right technology. For professional results, this means a compulsory mixer—a twin-shaft mixer for volume or a planetary mixer for precision.

- Third, decide your business model. This will guide your choice between a stationary plant and a flexible self-loading concrete mixer.

- Finally, look beyond the initial price. Consider the total cost of ownership, the quality of wear parts, and the reliability of the manufacturer.

This approach ensures you invest in a machine that will be a productive and profitable asset for many years to come.

Durable Machinery

Durable Machinery