How to Choose Charcoal Briquette Machines?

The selection of charcoal briquette production line equipment is a complex endeavor. It requires systematic consideration of various factors. These include raw material characteristics, final product specifications, process flow, and long-term operational stability. A common observation is that focus often centers solely on the briquette machine model and output. However, the entire production line functions as an integrated system. Its efficiency depends on raw material quality, binder science, and precise process control. Overlooking these deeper considerations can result in project inefficiencies or outright failure. This guide provides an objective framework for making informed decisions regarding biomass carbonization briquetting equipment.

Table of Contents

- Raw Material Types & Properties: How Do They Shape Equipment Configuration?

- Crushing & Drying Pre-treatment: How to Ensure Optimal Forming Standards?

- Charcoal Briquette Machine: Screw, Punch, Hydraulic—Advantages & Uses?

- Target Briquette Shape & Size: How Does It Influence Briquette Machine Choice?

- Carbonization Furnace Selection: Continuous vs. Intermittent—Balancing Capacity, Efficiency & Eco-Friendliness?

- Production Line Automation & Scale: How to Match Investment Budget with Expected Benefits?

- Equipment Quality, Durability & Stability: How to Ensure Long-Term High Efficiency?

- Environmental Standards & Energy Optimization: How to Choose a Compliant & Sustainable Solution?

- Comprehensive Cost & ROI Analysis: How to Make the Most Economic Choice?

- Supplier Evaluation: After-Sales Service & Technical Support—How to Ensure Peace of Mind?

- 2025 Latest Biomass Carbonization Briquetting Trends and Developments

- FAQs

- About Durable

Raw Material Types & Properties: How Do They Shape Equipment Configuration?

Charcoal powder suitability for briquetting is often misunderstood. Raw material characteristics critically influence product quality and burning performance. Key factors include particle size, fixed carbon content, ash content, and residual volatile matter. Briquette quality largely depends on the carbonization stage. Therefore, optimizing carbonization furnaces and crushing equipment is paramount before selecting briquette machinery.

Particle size distribution is crucial. Fine grinding enhances surface area, aiding binder distribution and increasing briquette density. An ideal size is often 80-120 mesh. However, very fine dust can increase safety risks and machine wear. Fixed carbon content correlates with heating value and smoke emissions, influenced by carbonization temperature and duration. Ash content from raw material impacts post-combustion residue. Lower ash is preferred for BBQ and hookah charcoal. Optimizing upstream carbonization and crushing processes is necessary. This ensures the carbonizer produces high fixed carbon, low ash charcoal at the required fine powder.

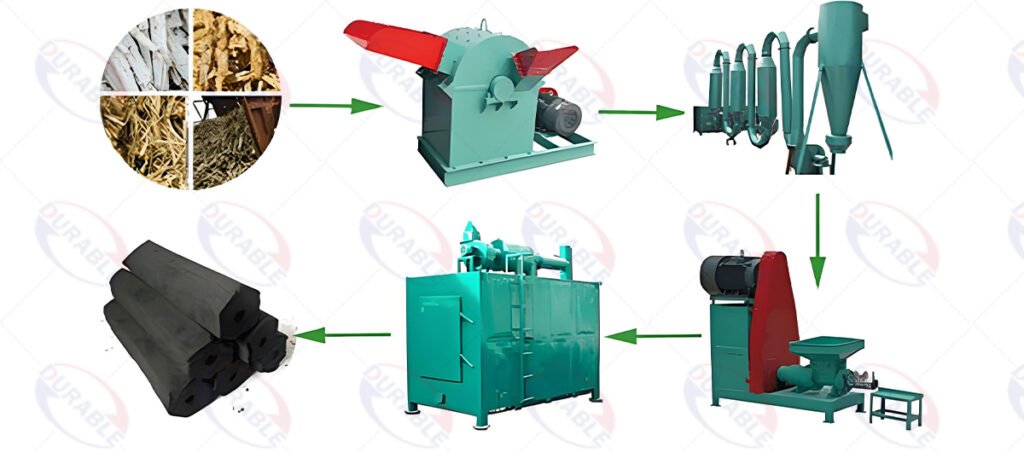

Crushing & Drying Pre-treatment: How to Ensure Optimal Forming Standards?

Effective pre-treatment, including crushing and drying, is vital for optimal briquette quality. This stage critically impacts briquette strength, density, and consistency. Inadequate pre-treatment results in weak briquettes, inefficient burning, and accelerated machine wear.

The crushing process is fundamental for material uniformity. Raw biomass must be reduced to a specific particle size, often 80-120 mesh, to create uniform charcoal powder. This consistency facilitates even binder distribution and results in compact, stable briquettes. Various crushers are available, such as hammer mill crusher for wood and raymond mill for fine charcoal powder.

Drying pre-treatment is equally important. High moisture in raw biomass reduces carbonization efficiency and increases energy consumption. Post-carbonization charcoal often requires further drying. The optimal moisture content for briquetting is typically 8-12%. Deviations cause briquettes to crumble or crack. Efficient raw material drying equipment, such as wood chips dryer, is employed. Proper drying also enhances binder activation, yielding stronger briquettes.

Charcoal Briquette Machine: Screw, Punch, Hydraulic—Advantages & Uses?

Briquette machines are not uniform in function. Different types vary significantly in forming principles, pressure levels, output capacities, and raw material adaptability. These distinctions directly influence the final product’s shape, density, and application. The appropriate machine type should be selected based on market positioning.

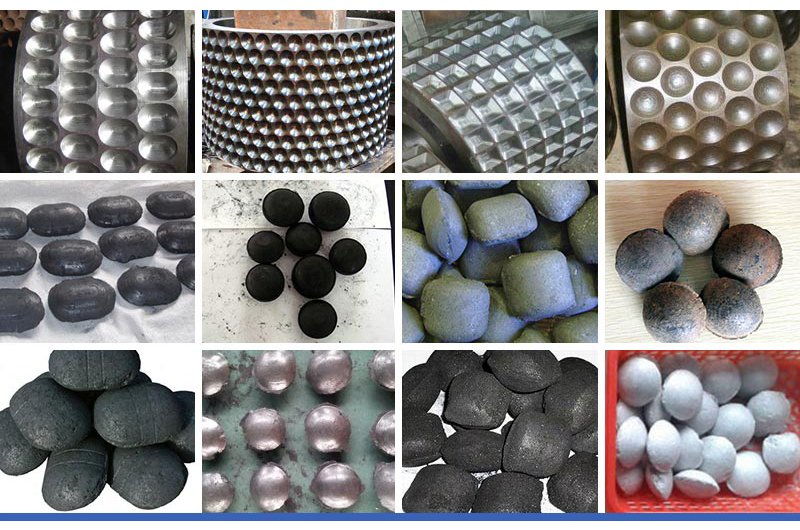

Roller Press Briquette Machines utilize counter-rotating rollers for material compression. These machines produce diverse shapes (pillow, ball, oval) with high density and large output. They are widely used for BBQ and industrial charcoal, which demand high strength and uniformity. Specific particle size adherence and precise binder proportions are necessary. Roller molds are primary wearing parts; their material and heat treatment are critical for longevity. The charcoal coal ball press machine exemplifies this technology.

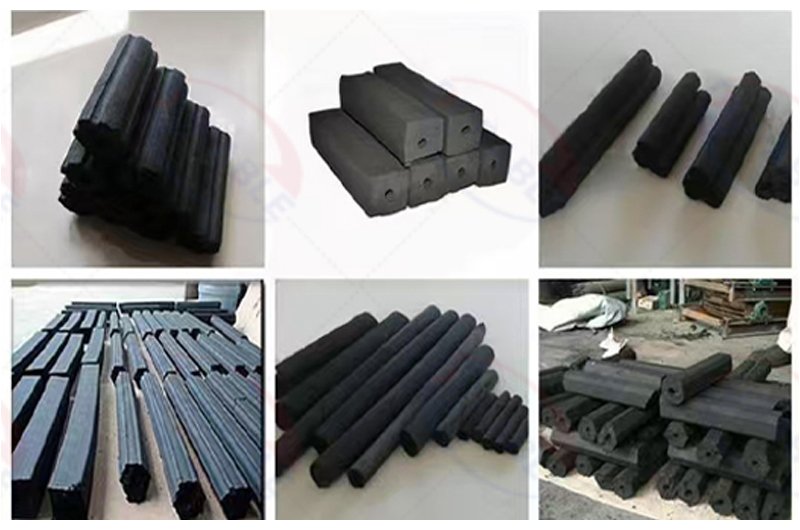

Screw Extruder Briquette Machines compress material using a screw propeller. These generate high-density, rod-shaped briquettes, often with a central hole, and allow continuous operation. For charcoal powder, binders are essential. Applications include hookah charcoal and industrial charcoal requiring high density and ignition points. Raw material moisture content is critical, and preheating may be necessary. The screw propeller and forming dies are high-wear components, requiring specialized wear-resistant alloy steel. The biomass briquette machine uses this technology.

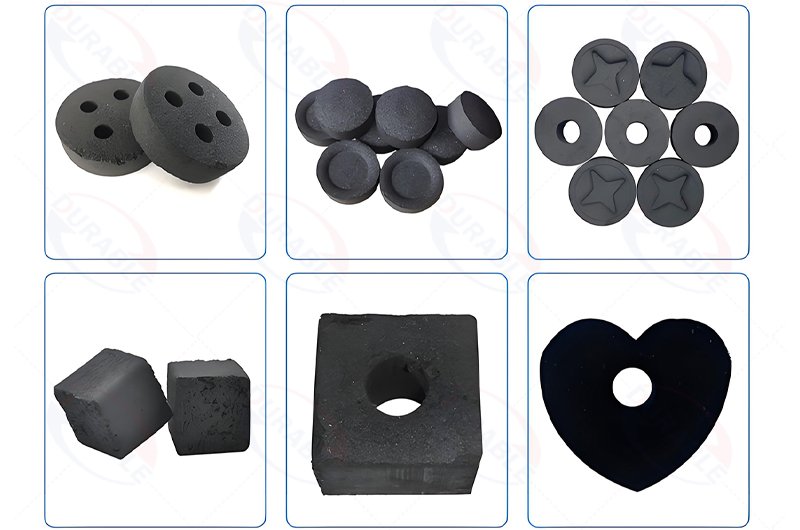

Shisha Hookah Press Machine utilize a high-pressure punch to compact material into a mold. These machines produce high-density, precise shapes like cubes or cylinders. Their primary use is for high-end hookah charcoal, offering high precision and consistency. Output is comparatively lower, and mold costs are elevated. The shisha hookah press machine is designed for this application.

Briquette machine selection should align with target market requirements. A roller press is common for BBQ charcoal. High-quality hookah charcoal may necessitate a screw extruder or punch press. Secondary cutting equipment should also be considered.

Target Briquette Shape & Size: How Does It Influence Briquette Machine Choice?

The desired shape and size of charcoal briquettes directly impact briquette machine selection. This decision influences functionality, market appeal, and production efficiency. Various shapes and sizes cater to distinct end-user applications and preferences.

Pillow-shaped or spherical briquettes are popular for BBQ charcoal. Their form facilitates good airflow for combustion and efficient stacking. A roller press briquette machine is ideal for these shapes, generating uniform, high-density briquettes. This ensures predictable burning times. Diverse sizes are achievable through mold changes.

Rod-shaped or hexagonal briquettes, often with a central hole, are common for industrial heating. The central hole improves heat transfer and burning efficiency. A screw extruder briquette machine produces these dense, uniform rods. The extrusion process compacts material for high-density briquettes with extended burning characteristics.

For premium products like hookah charcoal, cube or cylinder shapes are favored. These require exceptionally high density and precise dimensions. A punch press briquette machine is optimal, using high pressure for outstanding consistency and minimal breakage. Output may be lower than roller presses, but quality meets exacting hookah market standards. Careful market segment and product application analysis guides the briquette forming machine selection.

Carbonization Furnace Selection: Continuous vs. Intermittent—Balancing Capacity, Efficiency & Eco-Friendliness?

The choice of carbonization furnace profoundly impacts the briquette production line, affecting capacity, operational efficiency, and environmental adherence. Selecting between continuous and intermittent furnaces requires careful evaluation of project requirements.

An intermittent carbonization furnace processes biomass in distinct batches. This type is generally simpler and less expensive, suitable for smaller production volumes or irregular raw material supply. It offers operational flexibility. However, these furnaces exhibit lower heat efficiency due to cooling/reheating cycles and demand more manual labor. Models like the horizontal charcoal carbonization furnace are available.

A continuous carbonization furnace operates without interruption. Raw material enters one end, charcoal exits the other, maintaining a consistent high temperature. This design offers significantly higher efficiency and superior energy utilization. It is ideal for large-scale production requiring a steady supply of uniform raw material. Continuous furnaces often incorporate automated systems, reducing labor costs. They also feature integrated energy recovery, enhancing eco-friendliness and long-term cost-effectiveness. The square continuous biomass carbonization furnace and rotary drum biomass carbonization furnace exemplify this technology.

The decision should align with planned production scale and raw material availability. For high volume, consistent product quality, and reduced operating costs, a continuous system represents a superior investment. It meets modern biomass carbonization equipment standards for efficiency and environmental protection.

Production Line Automation & Scale: How to Match Investment Budget with Expected Benefits?

The level of automation and production line scale directly influence the investment budget and anticipated benefits. Opting for manual operations and discrete equipment to save initial costs frequently creates bottlenecks. For large-scale charcoal briquette production, automation and integration serve as significant multipliers for long-term profitability.

Investing in higher automation increases initial capital expenditure but substantially reduces long-term operating costs. Labor expenses decrease, energy consumption becomes more efficient, and waste rates decline. Production capacity and product quality consistency improve. Automated systems, including automatic batching systems, precisely control ratios for consistent product quality.

Continuous conveying systems (belt, screw, bucket elevators) minimize manual handling and enhance efficiency across the line. These systems are essential for smooth, uninterrupted production flow. A central control system provides centralized monitoring and adjustment capabilities for the entire production line, optimizing production parameters. This approach boosts efficiency and provides greater control over product quality. While automation involves higher upfront investment, long-term savings and improved quality make it a judicious decision for profitable charcoal briquette production line equipment.

Equipment Quality, Durability & Stability: How to Ensure Long-Term High Efficiency?

Long-term high efficiency from charcoal briquette production line equipment fundamentally depends on its quality, durability, and stability. Overlooking these for initial purchase price can lead to frequent breakdowns, high maintenance costs, and production losses. High-quality machinery delivers consistent performance, reduces downtime, and secures a superior return on investment.

When evaluating equipment, close attention must be paid to the materials used in construction. High-wear components, such as crusher blades, rollers, and molds, must be fabricated from wear-resistant alloys. For example, the comprehensive crusher features robust materials for extended lifespan. Quality materials ensure longer service life and fewer replacements. Manufacturing precision and assembly quality should also be assessed. Well-engineered components minimize friction and wear, leading to smoother operation.

Stability refers to the equipment’s capacity to maintain performance under continuous operation. Sturdy frames, reliable motor systems, minimal vibrations, and consistent temperature control are essential. Rotary drum biomass carbonization furnaces are designed for stable operation, preventing product quality shifts. Durability extends to electrical and control systems. High-quality electrical components and reputable brands for motors, sensors, and PLCs ensure reliable automation and safety. Investing in superior quality, durability, and stability protects production schedules and guarantees consistent output of high-quality biomass carbonization briquetting equipment, fostering profitability.

Environmental Standards & Energy Optimization: How to Choose a Compliant & Sustainable Solution?

Environmental compliance and energy optimization are imperative for sustainable and profitable operations. Dust explosion risks and exhaust gas emissions are often overlooked until accidents or non-compliance occur. Adhering to regulatory requirements and achieving energy efficiency are critical for long-term business viability and social responsibility.

Charcoal powder constitutes combustible dust, which can trigger a dust explosion when exposed to a spark. Therefore, effective dust control is paramount. Efficient dust collection systems (e.g., bag filters) are obligatory in crushing, mixing, conveying, and briquetting areas. Equipment must incorporate explosion-proof measures, safeguarding personnel and assets.

Exhaust gas treatment is a key area. The carbonization process generates smoke containing wood vinegar and wood tar, which necessitate recovery or safe emission. Drying also produces moist, hot air requiring treatment. Modern carbonization machines integrate advanced gas purification and recycling systems. These convert waste gases into energy for self-sustaining operations, minimizing harmful emissions.

Energy optimization is a strategic priority. Drying accounts for the largest energy consumption in the briquette production line. Utilizing waste heat from carbonization or biomass boilers for drying is crucial for cost reduction. Pure electric or fossil fuel heating can be prohibitively expensive. Dryers with heat recovery systems, such as the triple pass rotary drum dryer, significantly enhance thermal efficiency. Safety and environmental protection must be the highest investment priorities. Compliant dust collection and exhaust gas treatment equipment should be budgeted from the design stage, as it is vital for sustainable business development.

Comprehensive Cost & ROI Analysis: How to Make the Most Economic Choice?

Making the most economic choice for charcoal briquette production line equipment necessitates a comprehensive cost and return on investment (ROI) analysis. Focusing solely on the initial purchase price can obscure significant long-term costs. A thorough evaluation illuminates the true financial landscape and helps secure a profitable venture.

The analysis commences with calculating initial investment costs, including machinery, transportation, installation, civil works, and permits. Subsequently, operating costs are estimated. These recurring expenses cover raw materials, labor, energy, binders, and wear part replacements. Energy consumption, particularly for drying, can be substantial; utilizing waste heat from carbonization can significantly mitigate this cost.

Maintenance costs, including regular and periodic repairs, must be factored in. High-quality, durable equipment often entails lower maintenance requirements. Additionally, the cost of environmental compliance, encompassing dust collection and exhaust gas treatment systems, is an essential investment for sustainable operation.

Finally, revenue generation is projected from charcoal briquette sales and potential byproducts like wood vinegar or wood tar. The briquette yield rate and sales price are estimated. By comparing total projected costs with expected revenue, the return on investment period can be calculated. Automated lines may have higher initial costs but offer reduced long-term operating expenses and consistently higher output, leading to a faster ROI. Advanced biomass carbonization briquetting equipment is engineered for optimal cost-effectiveness. A detailed financial model guides economic and sustainable choices.

Supplier Evaluation: After-Sales Service & Technical Support—How to Ensure Peace of Mind?

Evaluating a supplier’s after-sales service and technical support is as critical as assessing the equipment itself. Operators often prioritize machine features, overlooking post-sale assistance. Insufficient support can result in significant downtime, costly repairs, and project failure. Selecting a supplier dedicated to long-term client success is essential for peace of mind.

- Supplier’s Reputation and Experience:

- Investigate the supplier’s reputation and experience.

- Long-standing manufacturers often possess extensive industry knowledge.

- Requesting references or case studies helps verify claims.

- Technical Support Capabilities:

- Examine technical support capabilities, including qualified engineers for installation/commissioning.

- Ensure on-site operator training is provided for efficient and safe machinery operation (e.g., continuous carbonization furnaces).

- Spare Parts Availability, Supply Chain, and Warranty:

- Understand spare parts availability and the efficiency of the supply chain to minimize downtime.

- Clarify warranty periods and coverage.

- Remote Support Options:

- Assess remote support options, such as troubleshooting via phone or online channels, particularly important for international clients.

- Long-term Partnership and Full-Service Support:

- Seek a supplier offering a long-term partnership, including ongoing technical upgrades and process optimization advice.

- Comprehensive full-service support ensures equipment operates efficiently for many years.

2025 Latest Biomass Carbonization Briquetting Trends and Developments

The biomass carbonization and briquetting sector is undergoing rapid innovation. Emerging trends are enhancing production efficiency, sustainability, and profitability. These developments significantly influence the selection of charcoal briquette production line equipment.

Latest Progress Overview:

- Advanced IoT and AI Integration: Intelligent machines use IoT sensors for real-time data collection (temperature, pressure, moisture, output). AI algorithms optimize process parameters, leading to higher yields, improved consistency, and proactive maintenance.

- Enhanced Waste Heat Recovery Systems: Focus is on maximizing energy reuse. New designs capture and utilize more carbonization waste heat. This heat powers drying or generates electricity, increasing plant self-sufficiency and reducing costs.

- Modular and Scalable Plant Designs: Modular components allow easier expansion or reconfiguration. This provides flexibility for businesses to scale up or adapt to changing raw materials or market demands, simplifying installation and maintenance.

The global market for biomass carbonization briquetting equipment is experiencing robust growth. This expansion is driven by demand for sustainable energy sources and effective waste management solutions. Stricter environmental regulations and circular economy models further stimulate this demand. Companies prioritize equipment offering high efficiency, minimal emissions, and robust reliability. This trend results in significant investment in advanced, integrated production lines, ensuring environmental compliance and economic viability.

FAQs

Question 1: What is the ideal moisture content for biomass before briquetting?

The ideal moisture content for biomass before briquetting is typically 8-12%. This range helps achieve optimal briquette density and strength.

Question 2: Can a charcoal briquette machine process different types of raw materials?

Most machines can handle various biomass types. However, proper pre-treatment (crushing, drying) is necessary for each specific raw material to ensure consistent quality.

Question 3: How does binder type affect briquette quality?

Binder type significantly affects briquette strength, burning characteristics, smoke, and smell. Starch-based binders are common. Modified binders enhance specific properties like water resistance.

Question 4: What are the benefits of using a continuous carbonization furnace?

Continuous carbonization furnaces offer higher efficiency, lower operating costs, consistent product quality, and better energy recovery. They are ideal for large-scale production.

Question 5: How can energy consumption be reduced in a briquette production line?

Energy consumption can be reduced by optimizing raw material drying, utilizing waste heat from carbonization, and choosing energy-efficient equipment with heat recovery systems.

Question 6: What safety measures are crucial for a charcoal briquette production line?

Crucial safety measures include effective dust collection systems, explosion-proof equipment, and proper ventilation. This prevents dust explosions and ensures operator safety.

About Durable

Durable, established in 2001, is a leading Chinese manufacturer. The company specializes in mineral processing equipment and construction machinery. It also applies its industrial process knowledge to biomass carbonization briquetting equipment. Durable designs and builds complete, integrated charcoal production lines. Its solutions prioritize efficiency, reliability, and environmental responsibility. Understanding that every project is unique, Durable’s team collaborates closely with clients. Systems are designed to match specific biomass types, production needs, and business objectives. From initial consultations and plant design to custom equipment manufacturing, installation support, operator training, and comprehensive after-sales service, Durable ensures client investment leads to successful outcomes.

For expert advice and a custom plan for a charcoal briquette production line equipment project, contact Durable’s engineering team today.

Durable Machinery

Durable Machinery