How to Dry Sand Quickly? A Guide to Sand Dryer Prices

If you work with sand for industrial use, you know that moisture is your enemy. Wet sand clogs machinery, ruins product quality for things like dry mix mortar, and is impossible to screen accurately. While sun-drying works for a small batch, you need a sand dryer for any commercial operation. This equipment is the only way to dry sand quickly and consistently. But what does a complete system cost?

As an engineer and manufacturer at Durable, I have helped hundreds of companies design and install sand drying systems. The price of a sand dryer is not just for one machine; it is for a complete production line. In this guide, I will explain the fastest drying methods. I will also break down all the factors that determine the final sand dryer price so you can plan your investment wisely.

Table of Contents

- What Are Fast Industrial Sand Drying Methods?

- Why Is a Three-Pass Dryer So Efficient?

- What’s in a Complete Sand Dryer System?

- What Factors Affect Sand Dryer Price?

- How Much Fuel Does It Take to Dry Sand?

- How Do I Get an Accurate Sand Dryer Quote?

- Frequently Asked Questions

- Summary and Final Advice

- About Durable

What Are Fast Industrial Sand Drying Methods?

For industrial needs, you cannot wait for the sun. You need a method that is fast, controllable, and reliable, no matter the weather. The industry standard solution for drying sand is the rotary dryer. This machine is a large, rotating metal cylinder that is slightly angled.

The process is simple and effective. Wet sand is fed into the higher end of the drum. Inside the drum, metal plates called “flights” lift the sand. As the drum rotates, the sand showers down through a stream of hot air from a furnace or burner. This creates maximum contact between the hot air and the sand particles. Gravity moves the sand down the slope of the drum. By the time the sand reaches the lower end, it is dry and ready for use. This method allows for a continuous process, drying sand at rates from a few tons to over 100 tons per hour.

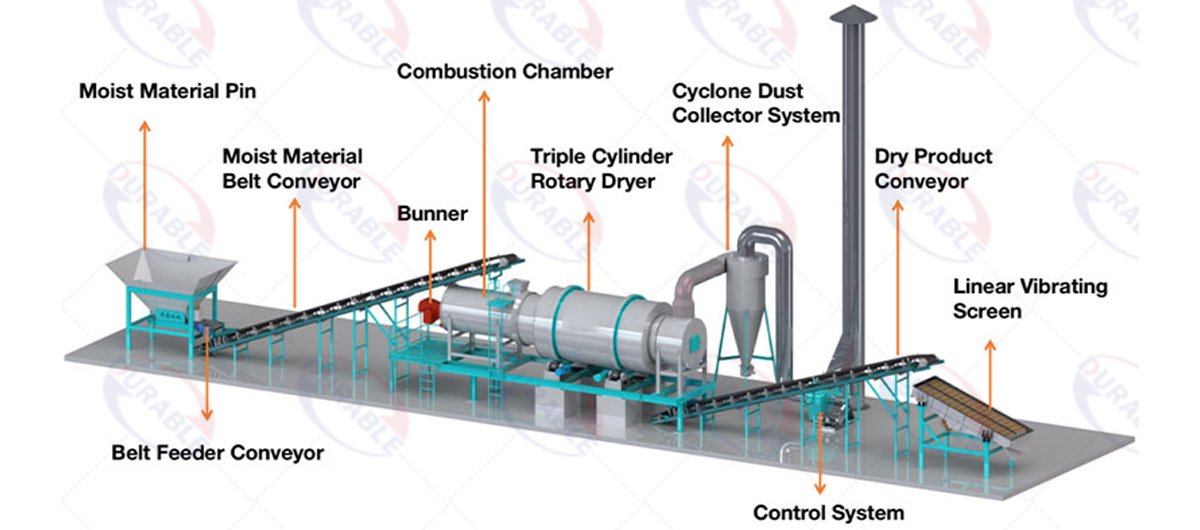

Why Is a Three-Pass Dryer So Efficient?

When customers ask me how to lower their sand drying cost, my first recommendation is often a three-pass dryer. While a standard single-pass rotary dryer is effective, the three-pass design is a major leap in efficiency. Think of it as making the sand travel three times the distance in a machine that is much shorter. This design uses three concentric drums, one inside the other. The wet sand is fed into the innermost drum. It travels the full length of the dryer, then is directed back through the middle drum, and finally travels forward again through the outermost drum before being discharged.

This long travel path means the sand stays in contact with the hot air for a much longer time. The heat that escapes the inner drum is used to heat the middle drum, and the heat from the middle drum is used for the outer drum. This brilliant design reuses the thermal energy multiple times. As a result, a three-pass dryer can reduce fuel consumption by 30-50% compared to a single-pass dryer with the same dryer capacity. It also has a smaller physical footprint, saving valuable space in your facility. For any business serious about reducing operational costs, this advanced type of sand dryer is the smartest investment.

What’s in a Complete Sand Dryer System?

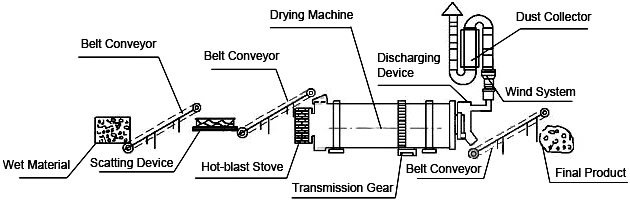

A rookie mistake is to only ask for the sand dryer price. A professional understands that you are buying a complete system. Each component is essential for smooth, safe, and efficient operation. A typical sand drying line includes more than just the main drum.

Here are the key parts of the system:

- Wet Sand Hopper and Feeder: This holds the wet sand and uses a vibrating feeder to deliver it to the conveyor at a consistent, controllable rate.

- Infeed Belt Conveyor: This transports the wet sand from the feeder into the dryer drum.

- Heat Source: This is the furnace or burner that generates the hot air. It can be fueled by coal, natural gas, diesel, or a biomass burner.

- Rotary Dryer Drum: This is the heart of the system where the sand is dried.

- Discharge Belt Conveyor: This carries the hot, dry sand away from the dryer to a storage silo or bagging area.

- Dust Collector: This is a critical component for safety and environmental protection. It captures the dust generated during the drying process.

- Control Panel: This is the brain of the operation, allowing you to control temperatures, motor speeds, and feeding rates.

What Factors Affect Sand Dryer Price?

The final sand dryer price can vary greatly. It depends on your specific production needs. When you ask for a quote, a good manufacturer will ask you many questions to determine the right machine for the job. The most important factors that influence the cost are capacity, moisture content, and the heat source. These three elements directly shape the size and complexity of the sand drying equipment.

For example, a machine designed to dry 50 tons per hour will be significantly larger and more expensive than one for 10 tons per hour. Likewise, drying sand from 20% moisture down to 0.5% requires much more energy and a bigger dryer than drying it from 8% to 1%. The type of fuel you plan to use also changes the price, as a coal furnace has a different construction and cost than a natural gas burner. Other factors include the material used to build the dryer (stainless steel costs more than carbon steel) and the level of environmental controls required for your location.

Key Price Factors

| Factor | How It Affects Price | Why It Matters for You |

|---|---|---|

| Capacity (Tons/Hour) | High Impact. Higher capacity requires a larger drum, bigger motor, and stronger frame. | This is the most direct driver of cost. Match the capacity to your business needs. |

| Moisture Removal | High Impact. Removing more water requires more energy and a larger, more powerful system. | You must know your initial and target moisture levels to get an accurate price. |

| Heat Source | Medium Impact. The cost of the furnace varies by fuel type (coal, gas, biomass). | Your choice depends on local fuel availability and cost, which affects your long-term sand drying cost. |

| Material | Medium Impact. Stainless steel is more expensive but required for corrosive materials. | For standard river sand dryer applications, carbon steel is usually sufficient and more affordable. |

| Dust Collection | Variable Impact. Stricter environmental rules require more advanced (and costly) dust collectors. | Investing in a good system avoids fines and ensures a safe work environment. |

How Much Fuel Does It Take to Dry Sand?

This is a critical question for calculating your operational sand drying cost. The answer depends on three things: the efficiency of your sand dryer, the amount of water you need to remove, and the type of fuel you use. A more efficient dryer, like a three-pass model, will use significantly less fuel.

As a general rule of thumb, it takes about 1.1 tons of standard coal or about 70-80 cubic meters of natural gas to evaporate 1 ton of water from your material. Let’s look at a practical example. Suppose you want to dry 100 tons of sand from 15% moisture down to 5%. This means you need to remove 10 tons of water (100 tons * (15% – 5%)). Based on our rule of thumb, you would need approximately 11 tons of coal or 700-800 cubic meters of natural gas. This shows why knowing your moisture content is so important for estimating your daily operational costs.

How Do I Get an Accurate Sand Dryer Quote?

To get a fast and accurate sand dryer price, you need to provide the manufacturer with specific details about your project. Sending a vague inquiry like “how much for a sand dryer” will only lead to more questions. Preparing this information beforehand will save you time and help us design the perfect system for you.

You should be ready to provide the following information:

- Material: What are you drying? (e.g., river sand, quartz sand, sea sand)

- Initial Moisture: What is the water content of your wet material? (e.g., 15%)

- Final Moisture: What is your target water content for the final product? (e.g., <1%)

- Capacity: How many tons do you need to dry per hour? (e.g., 20 TPH)

- Fuel: What fuel source is cheapest and most available for you? (e.g., natural gas, coal, biomass)

- Environmental Standards: What are the local emission requirements for dust?

With these details, our engineers can calculate the right size for the sand dryer machine, select the correct heat source, and configure the necessary dust collection system. This allows us to provide you with a detailed technical proposal and a precise price.

Frequently Asked Questions

1. What is the difference between a single-pass and a three-pass dryer?

A single-pass dryer sends sand through one long drum. A three-pass dryer uses three nested drums to make the sand travel three times the distance in a smaller machine. This makes it much more fuel-efficient.

2. How much does a small sand dryer system cost?

A complete small-scale system (e.g., 5-10 tons per hour), including all necessary components like feeders, conveyors, and dust collectors, typically ranges from $50,000 to $150,000 USD. The final price depends heavily on the factors listed above.

3. What is the best dust collector for a sand dryer?

For most applications, a two-stage system is best. It uses a cyclone separator to capture large, reusable dust particles and a baghouse filter to capture the very fine dust, ensuring you meet environmental standards.

Summary and Final Advice

Choosing the right sand drying equipment is a major investment that directly impacts your profitability. The key is to look beyond the initial sand dryer price and consider the long-term operational costs, especially fuel consumption. A highly efficient system like a three-pass dryer may cost more upfront but will save you a significant amount of money on fuel every day.

To make the right choice, work with a manufacturer who understands the entire process. Provide your detailed project requirements to get a proposal that is tailored to your specific needs. This will ensure you get a reliable, efficient, and cost-effective system that serves your business for years to come.

About Durable

Since 2001, Durable Machine has specialized in manufacturing high-performance mineral processing and drying equipment. We are a factory-direct B2B supplier with a presence in over 120 countries. Our team of experienced engineers provides full-service support, from designing your production line to installation, training, and after-sales service. We are experts in creating efficient solutions that lower your operational costs.

Ready to start your project? Contact our engineers today with your requirements to get a customized quote for your sand drying line.

Durable Machinery

Durable Machinery