How to Improve Slurry Dryer Efficiency: A Practical Guide

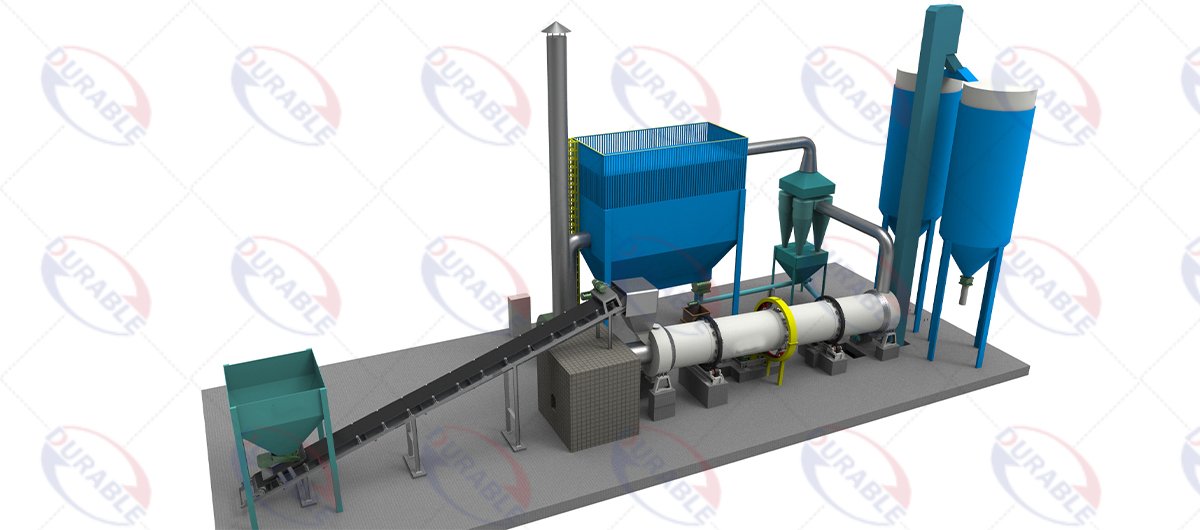

In many industrial operations, the slurry dryer can become a significant source of high operational costs, primarily due to excessive dryer energy consumption and suboptimal output. Inefficient drying processes lead to wasted fuel, decreased profitability, and frequent downtime.

Achieving high slurry dryer efficiency requires a systematic approach to dryer optimization. The process involves a comprehensive analysis of the entire system, from initial feed preparation to final product discharge. This guide outlines five critical areas for implementing effective strategies to increase dryer output, lower operational costs, and improve overall performance. By focusing on these key points, industrial facilities can transform their drying operations into a highly efficient and cost-effective process.

The Critical Importance of Pre-Dryer Slurry Dewatering

The most significant gains in slurry dryer efficiency are often achieved before the material enters the dryer. A common mistake is overloading the thermal dryer with excess water. The primary objective should be to minimize the amount of water fed into the dryer.

Removing water mechanically is hundreds of times more energy-efficient and cost-effective than thermal evaporation. The dryer should function as a final polishing step, not the primary water removal tool. A focus on slurry dewatering is essential.

Effective methods for reducing the drying cost through pre-treatment include:

- Maximizing Mechanical Dewatering: This is the foundational step for efficiency.

- Thickeners and Clarifiers: Utilizing gravity to settle solids is a zero-cost first step to increase slurry density.

- Filter Presses or Belt Presses: These devices can convert a high-moisture slurry (e.g., 80% moisture) into a solid filter cake (e.g., 30-40% moisture). This step alone can remove half the water load from the dryer without using any fuel.

- Screw Presses: For specific materials, screw presses can effectively squeeze additional moisture from thickened slurries or filter cakes.

- Implementing “Back-Mixing” for Feed Conditioning: This advanced technique transforms difficult, sticky materials into an ideal feed for the dryer.

- The Challenge: Wet filter cake is often sticky and lumpy, leading to dryer blockage, poor material flow, and inefficient drying.

- The Solution: A portion of the final, dry product is mixed back in with the wet feed cake before it enters the dryer.

- The Benefits: This process immediately lowers the overall moisture content and eliminates the stickiness of the feed. It creates a granular, friable material that flows smoothly and tumbles effectively, exposing maximum surface area to the hot gas stream. This greatly enhances the heat transfer rate and boosts overall slurry dryer efficiency.

Optimizing Speed and Temperature Parameters

With an optimized feed material, the next step is to fine-tune the dryer’s operational parameters. The performance inside a rotary dryer is determined by a precise balance between the inlet gas temperature, the drum’s rotational speed, and its inclination angle. These factors control the “residence time”—the duration the material spends inside the dryer. Achieving the optimal balance is crucial for maximizing slurry dryer efficiency.

Improper parameter settings can lead to significant operational issues:

- Insufficient Drying: If the drum speed is too high or the temperature is too low, the material exits before reaching the target moisture level. This results in an out-of-spec product or requires re-processing, doubling the energy cost.

- Over-Drying: If the speed is too low or the temperature is too high, excessive energy is consumed to remove more moisture than necessary. This wastes fuel, can damage the product, and reduces the total plant throughput, limiting the ability to increase dryer output.

The objective is to identify the “sweet spot” where the material exits at the precise target moisture content. This requires a systematic approach to dryer optimization. Begin with the recommended settings from the dryer operating procedures manual. Then, make small, incremental adjustments to a single variable while carefully measuring the final product moisture. This methodical process will reveal the most efficient settings for a specific material.

Eliminating Heat Loss from the Thermal System

A dryer is fundamentally a heat engine. Any thermal energy that does not contribute to water evaporation is a direct financial loss. A poorly managed dryer heat source and air system is a primary driver of high dryer energy consumption.

A thorough audit of the thermal system is necessary to identify and rectify inefficiencies.

- System Sealing: Air leakage is the foremost enemy of thermal efficiency. Cold ambient air infiltrating the dryer shell, particularly at the feed and discharge ends, drastically reduces the internal gas temperature. This forces the burner to operate at a higher capacity to compensate, consuming more fuel. Regular inspection and replacement of seals are mandatory for efficient operation.

- Comprehensive Insulation: All hot surfaces—including the dryer shell, the furnace, and hot gas ducting—radiate heat and waste energy. Any surface that is hot to the touch represents a significant energy loss. All such components must be thoroughly insulated and cladded to conserve thermal energy.

- Airflow Optimization (Negative Pressure): The drying system should operate under a slight negative pressure, controlled by the induced draft (ID) fan. This ensures a consistent flow of hot gas through the drum and prevents the escape of hot, dusty air into the facility. A manometer should be used to monitor this pressure. For advanced control, installing a Variable Frequency Drive (VFD) on the fan motor allows for precise airflow adjustments, leading to significant electricity savings.

Preventing Dryer Blockage and Material Adhesion

Dryer blockage is a frequent operational issue where material adheres to the internal walls or forms large agglomerates, reducing output and requiring shutdowns for cleaning. This problem typically occurs when the material passes through a “sticky phase” during the drying process.

While feed conditioning (dewatering and back-mixing) is the primary solution, the dryer’s internal mechanical design is also a critical factor.

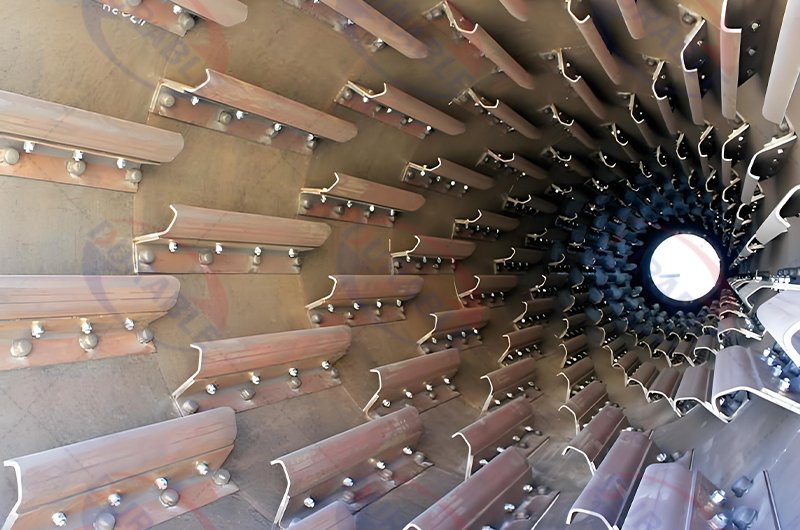

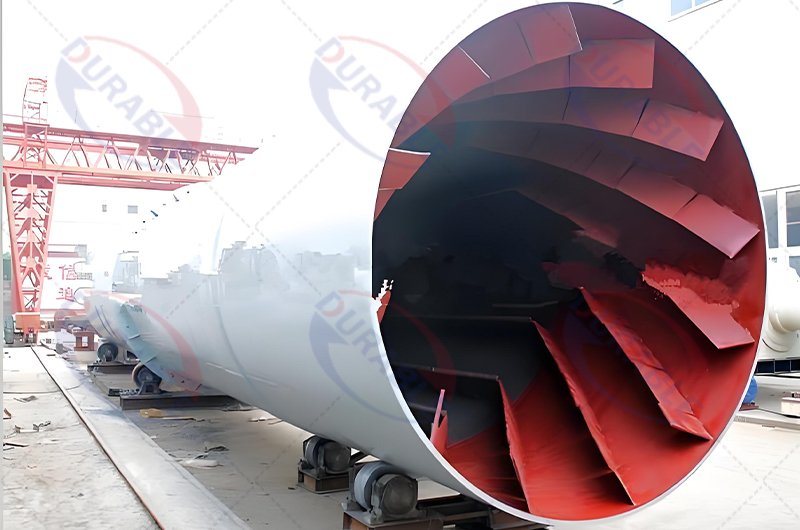

- Lifting Flight Integrity: The steel plates welded inside the dryer drum are known as “lifters” or “flights.” Their function is to lift the material and shower it through the hot gas stream. This action creates a “curtain” of material, maximizing contact between the particles and the hot gas for efficient heat transfer.

- Impact of Worn Lifters: If these lifters are worn, broken, or improperly designed, the curtain effect is diminished. The material will slide along the bottom of the drum in a dense mass, with only the surface layer being exposed to heat. This leads to inefficient drying and is a primary cause of low slurry dryer efficiency. A thorough internal inspection of the lifters during planned shutdowns is essential. Worn or damaged sections must be replaced to restore optimal performance. This aspect of dryer maintenance is crucial for applications like tailing dry stacking.

Implementing a Proactive Maintenance Program

Effective dryer maintenance is proactive, not reactive. A well-maintained machine operates at peak efficiency. The facility’s dryer operating procedures must include a structured, multi-level maintenance schedule to prevent failures and ensure reliability.

- Daily Inspections:

- Auditory checks for abnormal noises from bearings, drives, or fans.

- Visual checks for air leaks.

Durable Machinery

Durable Machinery