How to Make Charcoal Briquettes from Coconut Shells: A Complete Guide

With 50 years of experience in the biomass energy field, countless instances of coconut shells transforming into valuable resources have been observed. There have also been many attempts that failed due to a lack of understanding. The process of making charcoal from coconut shells and pressing them into briquettes is more than a simple chemical reaction. It is a precise system. It involves intricate details and requires significant experience. Many only perceive the equipment and basic operations.

This article will explain the hidden truths behind this process. It will detail how to produce high-quality coconut shell charcoal briquettes efficiently and economically. This method transforms “waste” into “high-value fuel.” It unlocks significant profits. It also offers substantial sustainable potential.

Table of Contents

- Coconut Shell Charcoal Briquettes: Why the High Value, and What’s the Market Outlook?

- What is the Complete Production Process for Coconut Shell Charcoal Briquettes?

- Coconut Shell Pre-Carbonization Preparation: What’s the Secret to Efficient Crushing and Drying of Raw Materials?

- Coconut Shell Carbonization Process: Which Carbonization Furnace Yields the Highest Quality Coconut Shell Charcoal?

- Post-Carbonization Treatment: How to Finely Grind Coconut Shell Charcoal into Powder?

- Binding and Mixing: How to Choose Eco-Friendly Binders and Ensure Uniform Charcoal Powder Briquetting?

- Charcoal Briquette Forming: How to Choose a Briquette Machine for High-Density, Uniformly Shaped Products?

- Briquette Drying and Cooling: How to Ensure Hardness and Storage Stability of Coconut Shell Charcoal Briquettes?

- Producing High-Quality Coconut Shell Charcoal Briquettes: Key Equipment and Automated Production Line Configuration

- What are the Quality Standards for Coconut Shell Charcoal Briquettes, and How Should They Be Strictly Controlled?

- Investing in a Coconut Shell Charcoal Briquette Production Line: How to Analyze Costs and Return on Investment?

- FAQs

- Conclusion

- About Durable

Coconut Shell Charcoal Briquettes: Why the High Value, and What’s the Market Outlook?

Coconut shell charcoal briquettes have become a high-value raw material. The market for these briquettes shows strong growth. This product offers many benefits. It comes from an abundant waste material. This makes it a sustainable resource.

Coconut shells, an industry byproduct once discarded, are now profitably processed into valuable charcoal briquettes, utilizing agricultural waste and addressing environmental concerns. These briquettes offer high calorific value, low ash, and minimal smoke/odor, popular in sectors like barbecues, industrial boilers, and shisha. High fixed carbon ensures long-lasting heat, while their porous structure allows odor absorption and water filtration, expanding applications beyond just fuel.

The market outlook is highly positive. Growing global demand for sustainable, eco-friendly fuel drives this, as coconut briquettes offer a deforestation-reducing alternative to traditional wood charcoal. Developing countries gain jobs and income from waste, while developed nations import them for quality and environmental advantages. Rapid growth in shisha and industrial markets, alongside their versatility and environmental benefits, ensures a promising future.

What is the Complete Production Process for Coconut Shell Charcoal Briquettes?

The complete coconut shell charcoal briquette process transforms raw coconut shells into a premium product. This process is complex. It involves several key stages. Each stage is crucial for ensuring the quality and efficiency of the final product.

Raw coconut shells first undergo pretreatment: crushing to a manageable size and drying to remove moisture for efficient pyrolysis. Next, crushed, dried shells are carbonized in an oxygen-free environment, converting them into raw charcoal. This raw charcoal is then cooled and ground into a fine powder, which is mixed with a binder for cohesion. A briquette machine presses this mixture into uniform briquettes. Finally, the briquettes are dried and cooled to harden them and ensure stability. Each vital step in this optimized process yields high-quality coconut shell charcoal briquettes.

| Stage of Production | Key Activities | Purpose |

|---|---|---|

| Pretreatment | Crushing, Drying | Prepare raw material for efficient carbonization |

| Carbonization | Heating shells without oxygen | Convert biomass into charcoal |

| Post-Carbonization | Cooling, Grinding | Prepare charcoal for briquetting |

| Mixing | Add binder to charcoal powder | Create cohesive mixture for shaping |

| Briquetting | Press mixture into molds | Form charcoal into desired shapes |

| Final Treatment | Drying, Cooling | Harden briquettes, ensure storage stability |

Coconut Shell Pre-Carbonization Preparation: What’s the Secret to Efficient Crushing and Drying of Raw Materials?

Many projects have encountered issues not because of a faulty carbonization furnace, but due to improper handling of coconut shell raw materials. A common misconception is that coconut shells are “dry” enough for direct carbonization. Experienced professionals emphasize that the quality of raw material pretreatment dictates the efficiency of carbonization, the upper limit of product quality, and the lower bound of operational costs. This represents the core of efficient crushing and drying.

Coconut shells, despite appearing dry, retain moisture within their fibrous structure. Their high density and low thermal conductivity hinder efficient moisture release. The optimal moisture content for carbonization should be below 15%, with a preference for under 10%. Excessively high moisture content leads to several negative consequences. It significantly increases energy consumption. The carbonization furnace expends additional energy to evaporate water, thereby reducing carbonization efficiency. This also lowers charcoal yield. Water vapor carries away some volatile components, which impacts the charcoal recovery rate. Furthermore, it adversely affects charcoal quality, resulting in uneven carbonization and a softer charcoal texture.

Crushing bulky raw coconut shells is the critical initial step. A coconut shell crusher or a drum chipper reduces them to a uniform size, improving heat penetration, handling, and drying. Essential drying, often via a rotary drum dryer or a cocopeat dryer, can utilize carbonization waste heat for energy efficiency. Simultaneously, removing impurities (sand, stones) is crucial to prevent increased ash and equipment wear. Although efficient pre-drying equipment requires initial investment, it significantly boosts carbonization furnace capacity (15-30%) and cuts energy consumption, yielding rapid returns.

Coconut Shell Carbonization Process: Which Carbonization Furnace Yields the Highest Quality Coconut Shell Charcoal?

The coconut shell carbonization process is a controlled pyrolysis. It is not a simple burning. Many perceive carbonization as merely “cooking” the material. They overlook how temperature, time, and oxygen control crucially impact charcoal product quality. The choice of carbonization furnace is critical in this regard. It directly influences both the quality and yield of coconut shell charcoal.

Dense coconut shells demand precise carbonization temperatures. While low-temperature (300-450°C) yields more charcoal but higher volatiles, medium-temperature (450-600°C) is ideal, producing high fixed carbon, low ash, hard texture, and well-developed porosity. High-temperature (>600°C) boosts fixed carbon but reduces yield and requires robust furnace materials.

For optimal quality, a continuous carbonization furnace or rotary drum biomass carbonization furnace is recommended. Such furnaces, including a horizontal charcoal carbonization furnace, provide precise, segmented temperature control and efficiently recover syngas for self-sufficient heating and drying, creating an energy closed loop. Critical refractory materials and insulation ensure uniform temperature, low energy consumption, and extended equipment lifespan. A vertical hoist biomass carbonization furnace also offers good batch results.

Post-Carbonization Treatment: How to Finely Grind Coconut Shell Charcoal into Powder?

After carbonization, raw coconut shell charcoal requires cooling and grinding into a fine powder, essential for high-quality briquettes. Particle size distribution is critical for briquette strength, density, and burning characteristics – this is the “particle size magic.”

Many operators misunderstand ideal particle size. Coarse charcoal powder results in low-density, fragile, uneven-burning briquettes. Conversely, excessively fine charcoal powder increases binder consumption, causes demolding issues, and extends drying. An ideal particle size distribution is typically 0-3 millimeters, with approximately 60-70% falling within the 0-1 millimeter range.

A charcoal pulverizer or roller crusher achieves this precise fineness. The screen mesh size is vital: shisha charcoal needs extremely fine powder (e.g., 100-mesh) for smoothness and smoke-free burning, whereas barbecue charcoal allows for a coarser particle size. Efficient, wear-resistant pulverizing equipment and appropriate screen mesh sizes are crucial for cost control in this energy-intensive step, fundamental for producing superior coconut shell charcoal briquettes.

Binding and Mixing: How to Choose Eco-Friendly Binders and Ensure Uniform Charcoal Powder Briquetting?

Binders function as the “soul” of charcoal briquettes. Their selection and application directly influence the briquettes’ quality, production cost, and environmental footprint. A common practice involves simply using “starch” as a binder. However, this approach often overlooks the binder’s specific type, optimal quantity, and the necessary mixing process. Experience highlights that the binder acts as an “invisible formula.” It dictates the briquettes’ ultimate quality, overall cost, and eco-friendly attributes.

Binder profoundly impacts briquette strength (transport/storage), burning characteristics (smoke-free, odorless, duration), ash content, and production cost. Common binders like corn, cassava, or modified starch vary in stickiness, price, and burn; starch binders require gelatinization for maximum stickiness. For specialized markets (e.g., shisha) demanding low ash, high strength, and odorless burn, compound binders (starch with CMC or plant fibers) are necessary, reducing starch usage, improving strength, and lowering ash. A charcoal mixer (or wheel mill) ensures a uniform blend. Optimizing binder formula and mixing can significantly reduce binder usage (5-8% to 2-4%), cutting costs, maintaining quality, and making the coconut shell charcoal briquette process more efficient and eco-friendly.

Charcoal Briquette Forming: How to Choose a Briquette Machine for High-Density, Uniformly Shaped Products?

Selecting the correct briquette machine is crucial. It directly impacts the production of high-density, uniformly shaped coconut shell charcoal briquettes. Operators often choose a briquette machine without fully considering the desired output, specific shape requirements, or the product’s market positioning. It is crucial to emphasize that the selection of the briquette machine represents a balance between production efficiency and customization.

Various briquette machines cater to specific needs. Roller press briquette machines offer high-volume production of diverse, high-density shapes (pillow, oval, square) for barbecue/industrial charcoal; a charcoal coal ball press machine exemplifies this. Punching press briquette machines produce high-precision, high-density briquettes in specific forms (round, square, hexagonal) for shisha charcoal, like a shisha hookah press machine, though with lower output. Screw extrusion briquette machines create high-density charcoal rods, often seen in a biomass briquette machine for machine-made charcoal.

The mold material and its wear resistance are core aspects of briquette machines. For hard raw materials like coconut shell charcoal, mold wear occurs rapidly. Selecting high wear-resistant alloy steel molds (e.g., chrome-molybdenum steel) significantly extends mold life. It reduces maintenance costs. Mold temperature requires careful monitoring during the pressing process. Both excessively high or low temperatures can negatively affect the molding quality. Mold maintenance and replacement constitute a significant portion of briquette machine operating costs. Regular cleaning of molds helps prolong their lifespan. Using appropriate release agents, if necessary, also contributes to extended mold durability. This careful selection and maintenance are key for efficient coconut shell charcoal briquette making.

Briquette Drying and Cooling: How to Ensure Hardness and Storage Stability of Coconut Shell Charcoal Briquettes?

After briquetting, coconut shell charcoal briquettes require thorough drying and cooling to achieve optimal hardness, consistent burning, and prevent mold. This energy-intensive process, leveraging the “art of wind and heat,” is crucial for enhancing product value.

While natural air drying is low-cost but slow and weather-dependent (suitable for small scale), a mesh belt dryer offers high-efficiency, automated, and uniform drying with adjustable parameters. A triple pass rotary drum dryer can further reduce operating costs by utilizing waste heat from carbonization or biomass burners.

The drying process prioritizes a unique drying curve: starting with lower temperatures and gradually increasing them prevents rapid surface hardening that traps internal moisture. Proper drying ensures briquette strength, prevents crumbling, maintains stability during storage and transport, and avoids mold and quality degradation, ultimately guaranteeing customer satisfaction. This stage is vital for the overall quality of coconut shell charcoal briquettes.

Producing High-Quality Coconut Shell Charcoal Briquettes: Key Equipment and Automated Production Line Configuration

Producing high-quality coconut shell charcoal briquettes requires key equipment and an automated production line. However, modern briquette projects demand energy self-sufficiency and environmental compliance for long-term viability.

Crucially, waste heat and gas recovery from the carbonization furnace are essential. High-temperature flue gas is purified (dust, tar removal) to fuel the combustion chamber, making heat self-sufficient. Excess heat also dries materials, creating an energy closed loop. Valuable byproducts, tar and wood vinegar, are recovered via condensation; wood vinegar serves agriculture, wood tar as antiseptic or fuel. Flue gas purification ensures environmental compliance, often with high-efficiency exhaust treatment for stringent regulations.

These environmental investments, though increasing initial capital, yield significant benefits: reduced operating costs (fuel savings), additional income from byproducts, and enhanced project sustainability. This secures permits, avoids fines, and improves corporate image, as green products are increasingly favored. This careful configuration ensures an efficient coconut shell charcoal briquette production line, guaranteeing both high quality and environmental responsibility.

What are the Quality Standards for Coconut Shell Charcoal Briquettes, and How Should They Be Strictly Controlled?

Achieving success with coconut shell charcoal briquettes necessitates producing a consistent, high-quality product. Many operators consider their task complete once briquettes are formed. They often lack systematic quality control standards. It is consistently emphasized that continuous, strict quality control builds brand reputation. It also earns customer trust. Implementing a “five-level control” system is recommended. This system ensures quality from the raw material stage through to the finished product.

The first level involves raw material inspection. This includes verifying the moisture content of coconut shells. It also checks impurity levels. The consistency of the source material is also important. The second level focuses on carbonization process monitoring. This entails tracking the furnace temperature curve. It monitors gas output. It also checks the carbonization time. The third level is charcoal powder inspection. This includes assessing particle size distribution. It also checks fixed carbon, volatile matter, and ash content. The fourth level is binder inspection. This verifies concentration, viscosity, and the mixing ratio.

The fifth level focuses on comprehensive finished product testing. This includes strength tests (compressive and drop) to simulate transport conditions. Burning tests measure fixed carbon, ash, volatile matter, calorific value, and burning time, confirming smoke-free and odorless properties. Density tests measure briquette density. Simple lab equipment (muffle furnace, electronic balance, particle size analyzer) combined with standardized procedures ensures effective product quality control. Market insights show distinct requirements; for instance, shisha charcoal needs very low ash, high strength, and smoke-free burning. Strict adherence to these charcoal quality control measures is essential for success.

Investing in a Coconut Shell Charcoal Briquette Production Line: How to Analyze Costs and Return on Investment?

Investing in a coconut shell charcoal briquette production line requires meticulous analysis. This includes both the associated costs and the projected return on investment (ROI). Many project failures stem not from equipment flaws, but from inadequate financial planning. Understanding the true costs and potential returns is critical for a successful venture.

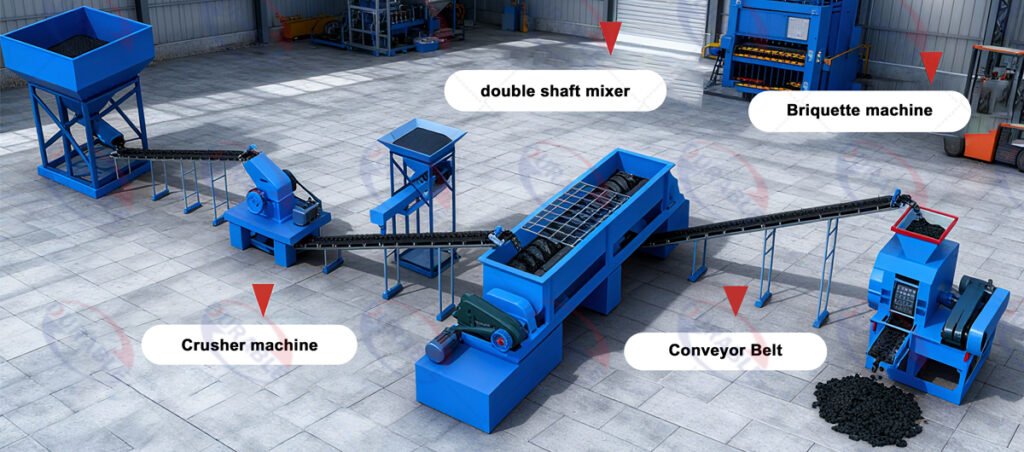

The total cost of investment comprises several components. First, there is the equipment cost. This includes the carbonization furnace, crushers (such as a hammer mill crusher), dryers (like a cocopeat dryer), briquette machines (for example, a shisha hookah press machine), mixers, conveyors, and environmental protection systems. Second, installation and commissioning costs are substantial. Third, civil works and land preparation are necessary expenditures. Fourth, working capital for raw materials, labor, and initial operations must be factored in. Fifth, permits and licenses add to the overall cost.

Operational costs encompass raw material sourcing (if purchased), labor wages, electricity, maintenance, and binder costs. However, an optimized coconut shell charcoal production line often achieves energy self-sufficiency. It recycles syngas to heat the furnace. This significantly reduces fuel expenses. Efficient drying also lowers energy costs. This directly impacts the overall charcoal production line cost.

Return on Investment (ROI) is influenced by several factors. Selling price varies by quality and demand, with high-quality coconut shell charcoal briquettes commanding premium prices. Production capacity directly impacts total revenue. Byproduct sales (e.g., wood vinegar) add revenue, and reduced coconut shell waste disposal contributes to savings. The market for coconut shell charcoal briquettes is growing due to increasing demand for sustainable fuels. A comprehensive financial analysis, projecting revenue and costs over the project’s lifespan, provides a clear picture of profitability, ensuring a strong charcoal equipment ROI.

FAQs

Question 1: Why have coconut shell charcoal briquettes become a high-value raw material, and what is their market outlook?

They are high-value due to abundant raw materials, high calorific value, low ash, and clean burn. The market outlook is strong, driven by increasing global demand for sustainable, eco-friendly fuels.

Question 2: What is the secret to efficient crushing and drying of raw materials before coconut shell carbonization?

The secret is achieving ideal moisture content (below 10-15%) and uniform particle size after crushing. This reduces energy consumption, increases carbonization efficiency, and improves charcoal quality.

Question 3: Which carbonization furnace yields the highest quality coconut shell charcoal?

Continuous or rotary drum carbonization furnaces yield the highest quality. They allow precise temperature control (450-600°C) and efficient syngas recovery, ensuring high fixed carbon and low ash.

Question 4: How to choose eco-friendly binders and ensure uniform charcoal powder briquetting?

Choose eco-friendly binders like gelatinized corn/cassava starch, or composite binders. Use a double-shaft or wheel mill mixer to ensure uniform blending of charcoal powder and binder, crucial for briquette strength and consistency.

Question 5: What are the quality standards for coconut shell charcoal briquettes, and how should they be strictly controlled?

Quality standards include fixed carbon, ash, calorific value, burning time, strength, density, and smoke/odor levels. Strict control involves “five-level control” from raw material to finished product testing, including specific lab analyses.

Conclusion

Creating coconut shell charcoal briquettes is a sophisticated process, transforming waste into a high-value product. It demands deep raw material understanding, precise carbonization control, and meticulous briquetting. Optimizing crushing, drying, carbonization, and selecting binders/machines ensures a superior final product. Automated lines and robust quality control enhance efficiency and competitiveness. Supported by sustainable practices (energy self-sufficiency, environmental compliance), this process offers significant profit and ecological benefits. This “alchemy” thrives on scientific management, continuous improvement, and keen market awareness.

About Durable

Durable Machine, established in 2001, is a prominent Chinese manufacturer. It specializes in mineral processing equipment and construction machinery. Durable also applies its industrial process knowledge to biomass energy equipment. Durable designs and constructs complete, integrated biomass fuel production lines. The company focuses on briquette machines and carbonization solutions. Its solutions prioritize efficiency, reliability, and environmental responsibility. Durable’s team collaborates closely with clients. It designs systems to match specific biomass types, production needs, and business goals. From initial consultations and plant design to custom equipment manufacturing, installation support, operator training, and comprehensive after-sales service, Durable ensures successful outcomes for its investments.

For expert advice and a custom plan for a coconut shell charcoal briquette making or horizontal charcoal carbonization furnace project, contact Durable‘s engineering team today.

Durable Machinery

Durable Machinery