How to Make Charcoal Briquettes: Ingredients and Process Guide

Learning how to make charcoal briquettes is about transforming low-value waste into a high-value, efficient fuel source. The charcoal briquette production process is a brilliant business model. You take agricultural or forestry waste like sawdust, rice husks, or straw, and turn it into uniform, dense biomass briquettes that burn longer and cleaner than traditional lump charcoal. This guide will walk you through the entire process, from preparing your raw materials to testing the final product.

The process is more than just pressing powder together. It is a science. You need the right ingredients, the right moisture content, and the right equipment. We will cover the essentials, including the role of the charcoal briquette machine and the critical carbonization step, to help you understand how to produce high-quality, smokeless charcoal.

Table of Contents

- Can I Use My Raw Materials Directly?

- Why is Raw Material Moisture So Critical?

- What Are the Ingredients of a Charcoal Briquette?

- How Does a Briquette Machine Create a Dense Briquette?

- Biomass Briquette vs. Charcoal Briquette: What’s the Difference?

- What Are the Advantages of Charcoal Briquettes?

- The Complete Charcoal Briquette Production Process

- What Core Equipment Do I Need for a Full Production Line?

- How Can I Test the Quality of My Finished Briquettes?

- Common Questions About Making Charcoal Briquettes

- Summary: Turning Waste into a Valuable Asset

- About Durable

- Start Your Charcoal Production Project Today

Can I Use My Raw Materials Directly?

No, you cannot use raw biomass like sawdust, rice husks, or straw directly to make charcoal briquettes. This is the most common misunderstanding for beginners. The raw material must first be processed into an intermediate product before it can be made into charcoal. There are two primary methods for this.

Method 1 is the most common and professional. The raw biomass is first compressed into high-density biomass briquettes (also called Pini-Kay or sawdust logs) using a biomass briquetting machine. These dense logs are then heated in a carbonization furnace to turn them into charcoal.

Method 2 involves carbonizing the loose raw biomass first to create bulk charcoal, then crushing this charcoal into a fine powder. This powder is then mixed with a binder and pressed into briquettes.

In both methods, the raw material must undergo a significant transformation before it becomes charcoal. You do not simply press sawdust and expect it to become a charcoal briquette. For sawdust to charcoal or rice husk charcoal, this initial processing is a mandatory first step.

Why is Raw Material Moisture So Critical?

The moisture content of your raw biomass is the single most important factor that will determine the success or failure of your briquettes.

- For Briquetting (Method 1): When making the initial biomass logs, the ideal moisture content of the raw material (sawdust, etc.) is between 8% and 12%.

- For Carbonization: High moisture content in the material being carbonized requires a massive amount of extra energy to boil off the water before the carbonization process can even begin. This wastes fuel and dramatically increases your production time.

Therefore, if your raw material is too wet, a rotary dryer is an essential piece of equipment in your production line to bring the moisture down to the optimal level.

What Are the Ingredients of a Charcoal Briquette?

A high-quality charcoal briquette is like a well-made recipe. It requires a few key ingredients mixed in the right proportions. This applies mainly to Method 2, where you briquette charcoal powder.

- Charcoal Powder (80-92%): This is the main fuel component. It is created by carbonizing your biomass and then crushing it into a fine powder (less than 5mm). The finer the powder, the denser and stronger the final briquette.

- Binder (3-10%): Charcoal powder will not stick together on its own. A binder acts as the glue. The best binder is starch (from cassava, corn, etc.) because it burns cleanly. Clay can also be used as a cheaper alternative, but it increases the ash content.

- Water (Variable): Water is used to activate the binder and give the mixture the right consistency for pressing. You want a damp, clumping mixture, not a wet slurry.

- Optional Additives: For specialized products like hookah charcoal, additives can be included to produce a white ash or make the briquettes easier to light.

How Does a Briquette Machine Create a Dense Briquette?

A biomass briquetting machine (or charcoal briquette machine) works by applying immense pressure and, in some cases, heat to the raw material. The most common type for making the initial biomass logs is a screw extruder.

This machine uses a high-powered motor to turn a specially designed screw. The raw material (e.g., sawdust) is fed into a hopper and drawn into the screw chamber. As the material is forced along the narrowing channel of the screw, it is subjected to extremely high pressure and friction. This intense pressure and the heat generated from friction cause the lignin, a natural polymer within the plant cells, to melt and act as a natural binder. The material is then forced through a shaped die, emerging as a very dense, hard, and solid log. No artificial binders are needed at this stage.

Biomass Briquette vs. Charcoal Briquette: What’s the Difference?

It is crucial to understand the distinction between these two products. They are not the same thing.

- Biomass Briquette: This is the intermediate product. It is a dense log made from compressed raw biomass like sawdust or straw. It is a good fuel in its own right and can be burned for industrial heating. However, it is not charcoal. It will produce smoke when burned.

- Charcoal Briquette: This is the final product. It is created by taking the biomass briquette and heating it in a carbonization furnace in the absence of oxygen. This process, called pyrolysis, drives off all the volatile compounds (like water, methane, and wood tar), leaving behind almost pure carbon. The final charcoal briquette is lightweight, black, and burns with no smoke and much higher heat.

What Are the Advantages of Charcoal Briquettes?

Using charcoal briquettes offers significant advantages over traditional lump charcoal or raw firewood.

- High Density and Uniform Shape: They are easy to pack, transport, and store. Their uniform size ensures consistent burning.

- Longer Burning Time: Because they are so dense, they burn for a much longer time than irregular lump charcoal.

- Higher Heat Value: The carbonization process concentrates the energy, giving them a higher calorific value.

- Smokeless and Odorless: Properly made charcoal briquettes are a source of smokeless charcoal, making them ideal for indoor use, grilling, and restaurants.

- Environmentally Friendly: This is a prime example of agricultural waste utilization. It turns waste materials that would otherwise rot or be burned in the open into a valuable fuel, reducing pollution and deforestation.

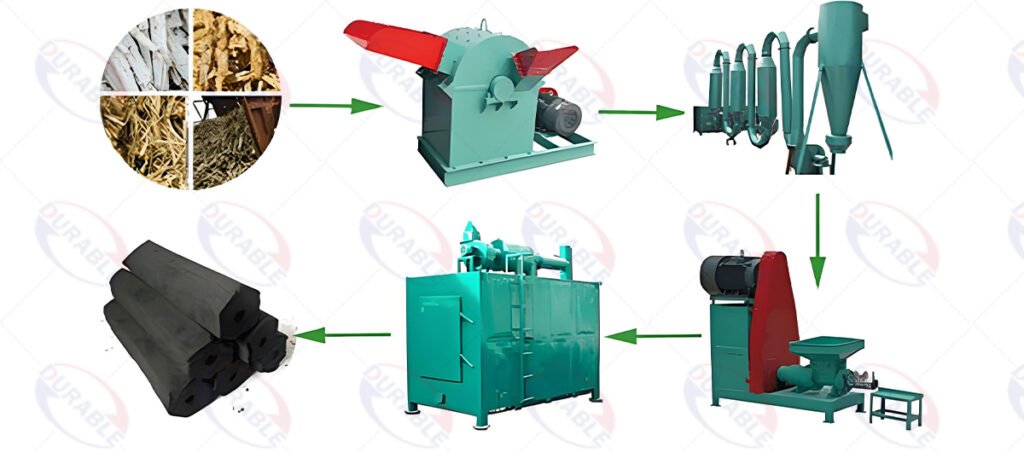

The Complete Charcoal Briquette Production Process

Here is the step-by-step industrial flow for producing high-quality charcoal briquettes using the professional Pini-Kay method.

- Crushing: If your raw biomass (e.g., wood branches, straw) is too large, it must first be crushed into a smaller, uniform size (typically under 10mm).

- Drying: The crushed material is fed into a rotary dryer to reduce its moisture content to the ideal 8-12% range.

- Briquetting: The dried material is fed into a biomass briquetting machine to be compressed into dense biomass logs.

- Carbonization: The biomass logs are carefully stacked inside a carbonization furnace. They are heated for several hours in a low-oxygen environment until they have completely transformed into charcoal.

- Cooling and Packaging: The charcoal briquettes are left to cool down completely before being packaged in bags for sale.

What Core Equipment Do I Need for a Full Production Line?

Setting up a complete production line requires a series of integrated machines. The charcoal production line cost will depend on the capacity and level of automation.

| Equipment Type | Its Function in the Process | Why You Need It |

|---|---|---|

| Carbonization Furnace | Converts raw biomass into charcoal. | This is the very first step to create your fuel base. |

| Hammer Mill Crusher | Grinds charcoal chunks into fine powder. | A fine powder is essential for making dense, strong briquettes. |

| Wheel Mixer | Blends charcoal, binder, and water. | Ensures every briquette has the same strong consistency. |

| Briquette Machine | Presses the mixed powder into shapes. | This forms your final product. |

| Dryer | Removes moisture from the fresh briquettes. | Hardens the briquettes and makes them smokeless. |

How Can I Test the Quality of My Finished Briquettes?

You can perform a few simple tests to ensure your charcoal briquettes are high quality.

- Drop Test: A good briquette should be able to survive a drop from a height of 1.5-2 meters onto a hard surface without shattering. This tests its density and strength.

- Burn Test: Light a briquette. It should ignite reasonably easily and burn with a steady, smokeless glow. There should be no sparks or foul odors.

- Ash Test: After it has completely burned, check the ash. The amount of ash should be low (typically under 5-10%). High ash content indicates either poor carbonization or the use of a cheap binder like clay. The ash should be fine and light grey or white.

Common Questions About Making Charcoal Briquettes

Question 1: What is the best raw material for making charcoal briquettes?

A:Hardwoods like oak and maple produce very high-density, long-burning charcoal. However, the “best” material is often the one that is most abundant and cheapest in your local area, such as sawdust, coconut shells, or rice husks.

Question 2: Why does my charcoal briquette produce smoke?

A:Smoke is usually a sign of incomplete carbonization. If the biomass logs were not heated long enough or at a high enough temperature, some volatile compounds remain. These compounds turn into smoke when the briquette is burned.

Question 3: Can I use a charcoal ball press machine instead?

A: Yes. The charcoal ball press machine is used in the second method. After carbonizing the loose biomass, you crush it into powder, mix it with a binder, and then use the ball press to form pillow-shaped or spherical briquettes.

Summary: Turning Waste into a Valuable Asset

The charcoal briquette production process is a proven and profitable way to engage in agricultural waste utilization. By understanding the critical role of moisture control, using the right equipment like the biomass briquetting machine and carbonization furnace, and following a systematic process, you can create a high-quality, in-demand fuel source. This process not only provides a valuable product but also contributes to a more sustainable and environmentally friendly energy solution.

About Durable

Durable is a leading Chinese manufacturer specializing in complete production lines for biomass and charcoal briquettes. Since 2001, we have designed and installed hundreds of systems worldwide. Our expertise covers everything from initial material analysis to final equipment commissioning. We provide robust, efficient machinery, including crushers, dryers, briquetting machines, and carbonization furnaces, to ensure our clients can produce the highest quality charcoal briquettes.

Start Your Charcoal Production Project Today

Are you ready to turn biomass waste into a profitable business? Contact our team of engineers. We can help you assess your raw materials, design a custom production line that fits your budget and capacity needs, and provide a comprehensive quote. Let us be your partner in building a successful charcoal briquetting operation.

Durable Machinery

Durable Machinery