Search the whole station liberty-fse

ECOBRB Clay Hydraulic Interlocking Brick Machine

Capacity: 1-2 pieces per mould; 1900-3900 pieces per 8 hours.

Power: Diesel Engine/Electric Motor

Moulding Type: Hydrualic pressure

Introduction:

Discover the ultimate in efficiency and power with the ECO BRB Hydraulic Brick Making Machine, a high-capacity solution engineered for large-scale construction projects. As an enhanced version of the renowned ECO Brava, this robust interlocking brick machine is designed to significantly boost your production output. By utilizing a formidable 60MPa hydraulic pressure system and advanced carburizing heat technology, the ECO BRB expertly forms high-density ecological clay bricks and cement blocks. Its innovative design produces two bricks per mold with a rapid 20-second cycle, making it a highly efficient clay brick making machine and cement block machine.

M7MI Hydraulic Clay Bricks Manufacturing Machine

Capacity:1-2 pieces per mould; 2400-4800 pieces per 8 hours (customize according to your brick size)

Power: Disel engine:12HP

Introduction:

Introducing the M7M1 Hydraulic Block Making Machine, a premier mobile brick manufacturing machine designed for ultimate portability and operational independence. Powered by a robust 12 Hp diesel engine, this machine is the perfect solution for projects in remote locations or areas plagued by electricity issues and load-shedding. Its design prioritizes ease of movement, allowing you to bring your production directly to the construction site. As an ideal diesel-powered brick machine for small businesses and startups, the M7M1 combines reliability with efficiency. It operates with a strong 16 MPa hydraulic pressure system and features a rapid molding cycle of just 15-20 seconds.

DM4-10 Earth Hydraulic Brick Press Machine Line

Capacity: 4 pieces per mould; 11520 pieces per 8 hours

Forming Cycle: Less than 10 Seconds

Brick Size: different clay Lego bricks, interlocking bricks, paver bricks etc..

Introduction:

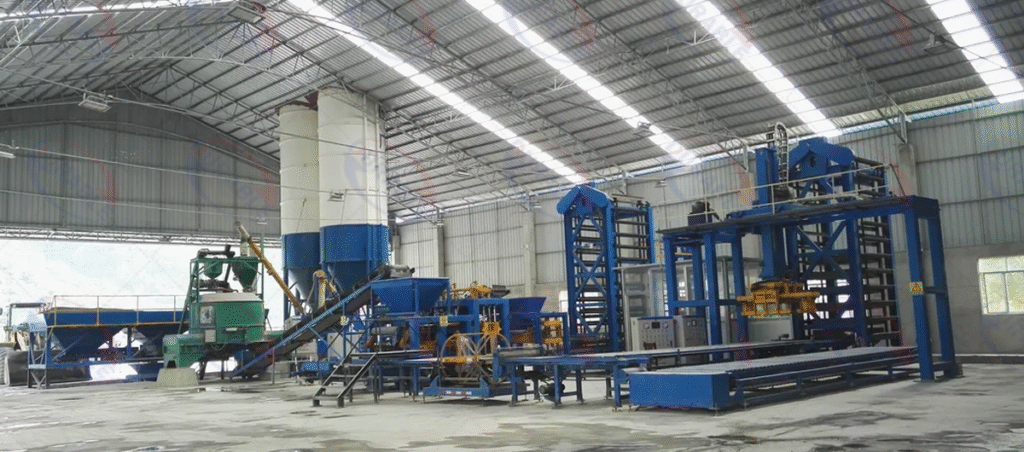

Discover the power of automation with the DM4-10 Automatic Hydraulic Clay Brick Production Line, the premier solution for large-scale brick manufacturing. At the heart of this system is a robust automatic hydraulic interlocking brick machine, meticulously engineered for high-volume output. It leverages an advanced PLC control system to guarantee exceptional precision in both material feeding and mold pressing, ensuring consistent quality in every block. Engineered as a high-yield investment for established brick businesses, the DM4-10 is designed to maximize profitability. With its powerful 21 MPa hydraulic pressure and an incredibly fast molding cycle of just 8-10 seconds, this high-capacity brick machine can produce up to 8,000 clay blocks in a single 8-hour shift.

QT4-16 Hydraulic Brick Press Machine Line

Capacity:4-28 pieces per drop, 7680-53760 pieces per 8 hours

Power:Electric Motor

Forming Cycle: 15-20 seconds

Introduction:

The QT4-18 Hydraulic Cement Brick Making Machine is a fully automatic and robust solution engineered for the demands of medium to large-scale construction businesses and brick manufacturing plants. At its core, the machine integrates a sophisticated PLC (Programmable Logic Controller) with a powerful hydraulic system, ensuring seamless, automated operation from material feeding to block molding. This making brick machine not only reduces labor dependency but also guarantees exceptional consistency in the quality, density, and strength of every brick produced. Boasting remarkable efficiency, the QT4-18 features an impressive molding cycle of just 15 to 18 seconds and operates on a standard 850x550mm pallet, enabling high-volume output to meet substantial project demands.

QMY6-25 Egg Laying Brick Making Equipment

Capacity:6-9 pieces per mould; about 9000-10000 pieces per 8 hours

Power:Electric Motor

Forming Cycle:25-30 seconds

Moulding Method: Mechanical Vibration Molding & Hydraulic Pressure

Introduction:

The QMY6A represents an innovative and highly practical approach to concrete block production machine, specifically designed for small to medium-sized enterprises, startups, and on-site construction projects. As a mobile brick making machine, “egg-laying” block machine, its most significant advantage is its pallet-free operation. The brick making machine moves along a flat concrete floor, laying rows of freshly molded blocks directly onto the ground for curing. This unique block pressing machine design completely eliminates the need for costly pallets and associated stacking equipment, resulting in a substantially lower initial investment and reduced operational complexity.

QT6-15 Cement Brick Production Machine Line

Capacity: 6 pieces per mould; 11520 pieces per 8 hours

Moulding Cycle: 10-15 seconds

Moulding Method: Mechanical Vibration Molding & Hydraulic Pressure

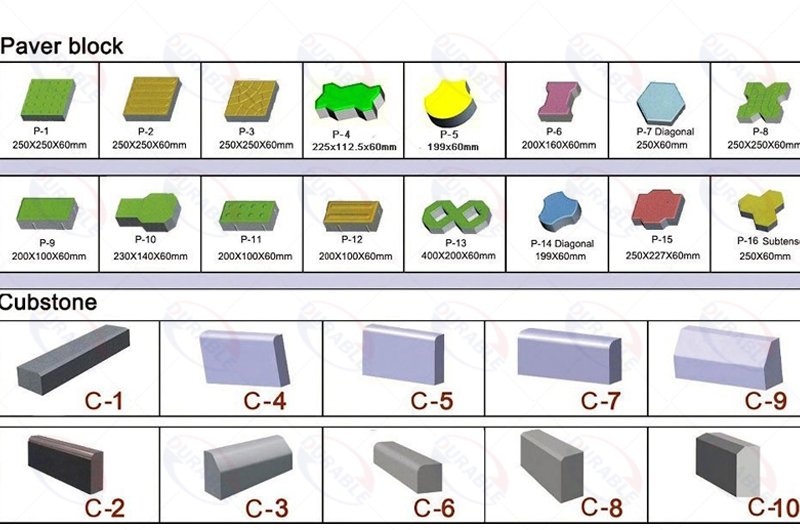

Block Size:Different sizes and shapes including 400*200*200mm;400*150*200mm;400*100*200mm hollow blocks, solid bricks, I Shape,H Shape,Z Shape paver & curbstone.

Introduction:

The QT6-15 is a fully automatic hydraulic block making machine designed for efficient, high-volume production. block press machine combines high-pressure hydraulics with powerful vibration to produce strong, high-density blocks in a rapid 15-20 second cycle. Highly versatile, it can manufacture a wide variety of products, including hollow blocks, interlocking pavers, and curbstones, simply by changing the mold. The QT6-15 automatic brick factory is an ideal solution for medium to large-scale producers seeking automation, reliability, and a high return on investment.

This guide provides a comprehensive overview of the hydraulic brick making machine, exploring its suitability for various projects. It covers essential aspects, from defining the hydraulic block machine and its operational principles (making brick machine) to highlighting the advantages of the automatic brick making machine and the necessary maintenance for the brick manufacturing machine. The guide also examines the hydraulic press brick machine and factors influencing the brick making machine price. DURABLE MACHINE is committed to supplying brick making machines that fulfill diverse brick-making requirements.

Last Updated: June 2025 | Estimated Reading Time: 15 minutes

A hydraulic brick making machine uses hydraulic pressure to compress and mold raw materials into machine bricks. These machine for brick making offer advantages over traditional mechanical presses, including higher compaction force, greater precision in producing bricks made machine, and increased production speed for automatic brick factory operations. The hydraulic block machine is used for manufacturing various types of bricks:

The versatility and efficiency of the making brick machine make it a choice for small-scale and large-scale brick production. Hydraulic block press machines are essential for construction businesses looking to streamline processes and improve product quality with bricks machine.

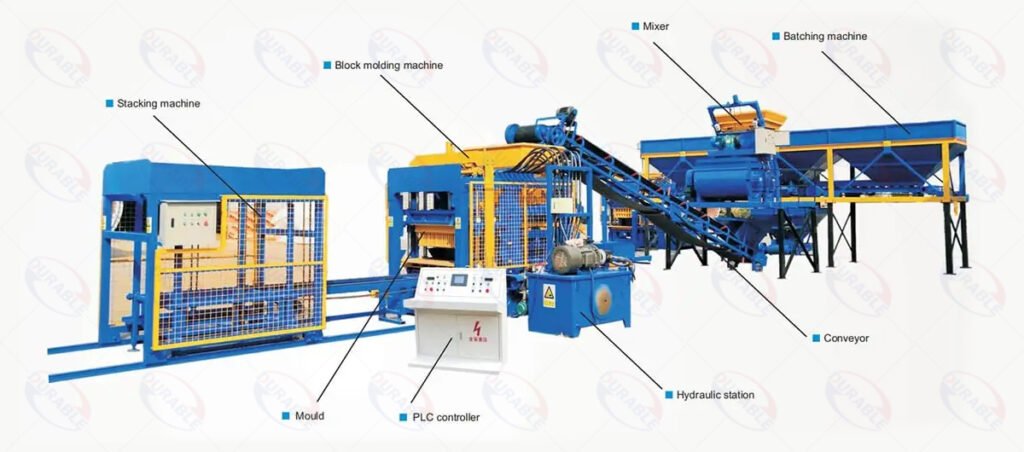

The structure of a hydraulic brick making machine is designed for strength and durability to ensure consistent bricks making machine production. The main components include:

A robust frame allows the machine to withstand the pressures involved in brick making with a hydraulic brick press. High-quality hydraulic cylinders are critical for performance in the making brick machine. Molds must be precisely engineered to produce bricks of the desired dimensions with a brick mold press.

A complete making bricks machine line includes the following components, making it a solution for brick making machines:

Each component ensures efficient brick production with a brick machine maker. A well-designed brick making line reduces labor costs and improves productivity with brick machines.

Hydraulic brick manufacturing machine offers features that make it a choice for brick production using a brick maker machine:

Manufacturers can meet client needs and improve their brick manufacturing machine price.

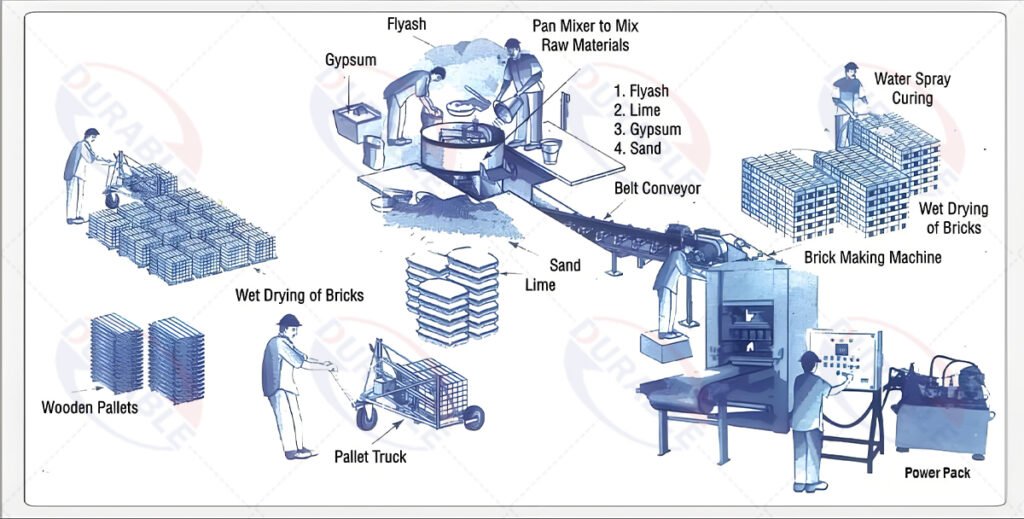

The working principle of hydraulic brick making machines for sale involves steps to produce bricks machine making:

Precise control ensures brick quality and production rates using a brick machine maker. The press brick process is efficient and minimizes waste with the hydraulic brick press machine.

A hydraulic brick press machine provides advantages for bricks making machine:

These advantages make the block press machine a solid investment for businesses looking to improve brick production and achieve a brick manufacturing machine price.

Hydraulic brick maker for sale machines can be classified based on factors to suit brick making machines needs:

Understanding these classifications helps to choose the machine for needs and budget, impacting the cost of brick making machine.

A hydraulic brick machine and a mechanical block machine differ in operation and performance, affecting the quality of bricks machine making:

The machine bricks produced by hydraulic systems exhibit quality, making them ideal for a brick machine maker.

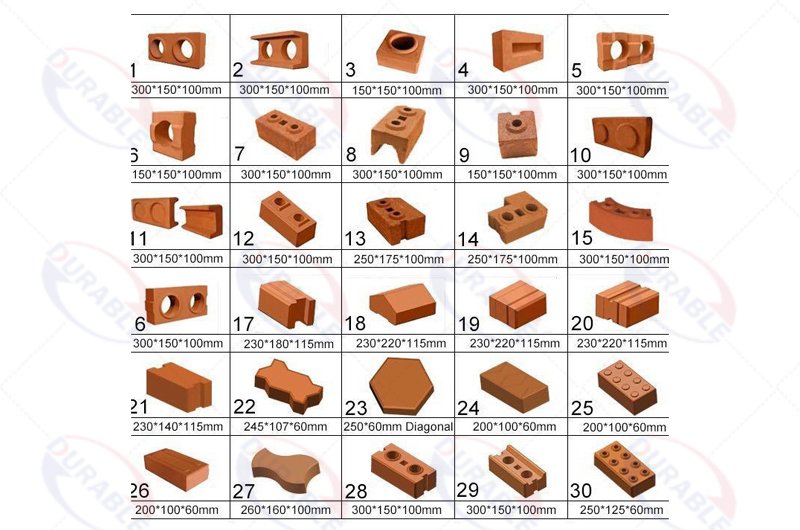

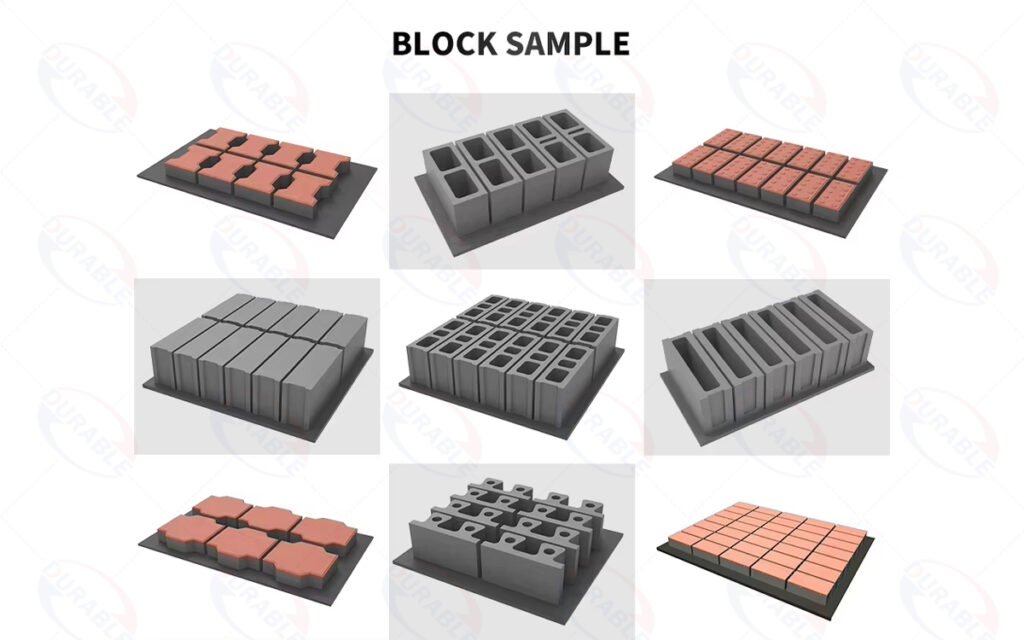

A hydraulic bricks made machine produces block designs by changing the molds, optimizing the brick mold press:

The versatility of automatic brick machines allows manufacturers to cater to construction needs and maintain a brick manufacturing machine price.

Bricks made with a hydraulic brick manufacturing machine are used in construction applications, increasing demand for brick making machines:

Their durability makes them a choice for building projects, leading to efficient brick manufacturing. The brick manufacturing machine ensures the production of quality bricks, ensuring automatic brick.

A hydraulic brick block making machine utilizes materials, making it a tool for the brick making factory:

The choice of material depends on the properties of the bricks, impacting the cost of brick making machine. The machine cement bricks production process is efficient.

The brick making machine price varies, so it’s important to consider needs and budget when purchasing brick making machines:

Consider budget, production needs, and level of automation when determining spending on a brick machine maker. A cheap brick making machine may seem attractive, but investing in a machine saves money through reduced downtime and improved brick quality with a brick manufacturing machine.

Choosing the right hydraulic brick making machines involves considerations to ensure bricks making machine:

DURABLE MACHINE has brick making machine for sale at rates, making investment in a brick machine maker worthwhile. A brick maker for sale can save time and money.

Regular maintenance keeps the hydraulic brick production machine in condition, ensuring bricks making machine:

Proper maintenance extends the lifespan of the machine, improving the brick manufacturing machine price. Hydraulic machines require maintenance, benefiting from a automatic brick factory.

Purchasing clay brick making equipment from China involves steps to ensure reliable brick making machines:

Purchasing from China can offer savings on brick making machines for sale, but it’s essential to conduct due diligence.

Choosing DURABLE MACHINE for brick-making equipment provides benefits, ensuring the best brick making machines:

DURABLE MACHINE is committed to providing brick-making solutions, helping to achieve brick making machines.