Investing in a Ready Mix Concrete Plant? A Guide to the 5 Core Systems

A wise concrete plant investment means seeing it as a synchronized system of interconnected parts, not just by its final product.Think of it as a large-scale industrial kitchen. Each component’s seamless integration is key to producing consistently high-quality concrete. My global experience designing these plants confirms that a successful operation starts with a solid understanding of its core anatomy. This guide breaks down the five essential concrete plant systems you need to know.

Table of Contents

- What is the Material Storage System?

- How Does the Conveying System Work?

- Why is the Weighing System So Critical?

- What is the Central Mixing System?

- How Does the Control System Automate Everything?

- Stationary vs. Mobile Plant: Which is Right for You?

- Frequently Asked Questions

- Summary and Recommendations

- About Durable

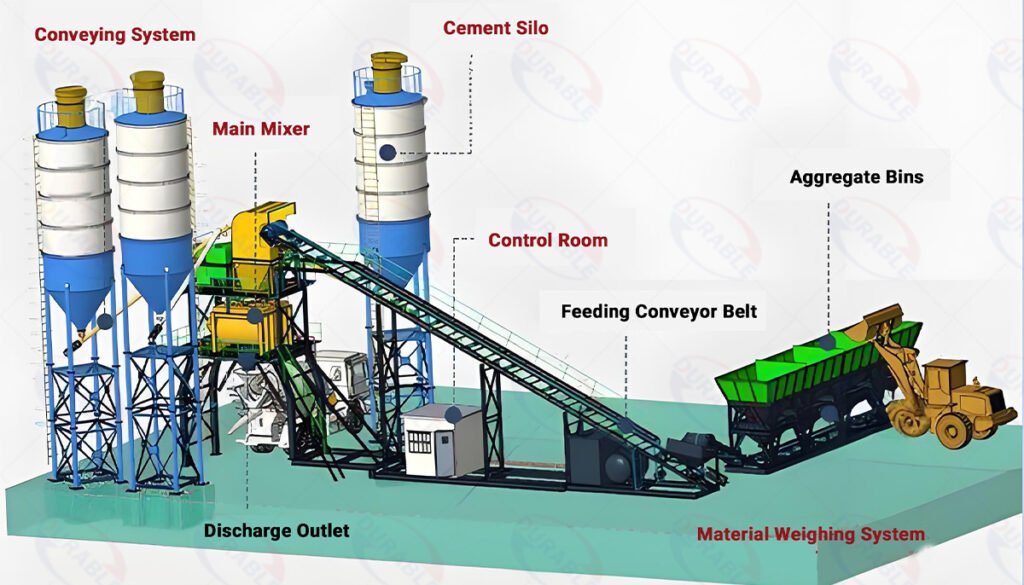

What is the Material Storage System?

Every ready mix concrete plant begins with the material storage system, where the plant safely stores primary ingredients like aggregates and powders before processing them. Proper storage is fundamental to quality control. You must keep aggregates separate and clean to prevent contamination of the final mix. Large, open-topped steel bins, known as aggregate hoppers, achieve this separation. They typically have three to six compartments for different materials such as fine sand, coarse sand, 10mm stone, and 20mm stone. A wheel loader continuously fills these bins from larger ground stockpiles.

Powdered materials, on the other hand, require a completely different approach. Keeping cement and additives like fly ash perfectly dry prevents premature hydration, which would otherwise cause them to harden and become useless.For this, we use tall, weatherproof, and sealed cement silos. These silos include crucial safety features like pressure relief valves to handle pressure changes during filling and level indicators to monitor inventory. This “pantry” of the plant protects all raw materials and keeps them ready for use, forming the first critical link in the production chain. Without a well-organized and properly functioning storage system, producing consistent concrete is impossible.

How Does the Conveying System Work?

The conveying system is the logistical network that moves stored ingredients for weighing and mixing. The efficiency and reliability of your concrete plant components are heavily dependent on this workflow. For aggregates, we use two primary methods.

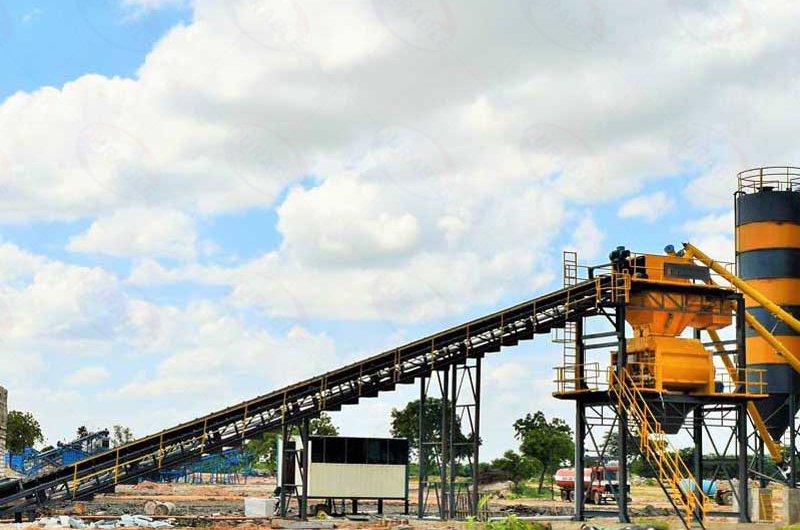

Larger, high-output stationary plants almost always use an inclined belt conveyor. This long conveyor belt efficiently transports the aggregates from the batcher up to the mixing tower. It offers high speed and continuous flow, which is ideal for large-scale production demands.

For compact layouts, skip hoists use a bucket on an inclined rail to batch-feed aggregates, saving space. For powders like cement, screw conveyors (augers) are standard, using a rotating screw for precise, dust-free transport. A well-designed conveying system ensures a smooth material flow, which is key to maximizing plant productivity.

Why is the Weighing System So Critical?

The weighing system, or batching system, is arguably the most critical part of a ready mix concrete plant for ensuring quality. This is where the plant’s control system executes the “recipe” for the concrete with digital precision.In modern concrete production, consistency is everything, and that consistency comes from accurately measuring every single ingredient for every single batch. Every component—aggregates, cement, water, and admixtures—is weighed using highly sensitive electronic sensors called load cells. This eliminates the guesswork and volume-based inaccuracies of older methods, guaranteeing that each batch meets the exact design specifications.

The weighing system consists of several dedicated hoppers:

- Aggregate Weigh Hopper: This large hopper weighs the different sands and stones, either cumulatively or separately, before sending them to the mixer.

- Cement Weigh Hopper: A smaller, fully enclosed hopper, suspended on its own load cells, receives cement from the screw conveyors.

- Water Weigh System: This system weighs water in a dedicated hopper (the most accurate method) or measures it with a high-precision digital flow meter.

- Admixture Scales: These small, highly precise scales measure chemical admixtures, which are used in small quantities, to ensure exact dosing.

The accuracy of these scales is non-negotiable. It directly impacts the concrete’s strength, workability, and durability. This system is the quality control center of the entire operation.

| Component | Function | Why It’s Critical for You |

|---|---|---|

| Aggregate Weigh Hopper | Accurately weighs sand and stones | Ensures the correct structural composition and strength |

| Cement Weigh Hopper | Precisely measures cement and powders | Directly controls the concrete’s binding properties |

| Water Weigh System | Measures the exact amount of water | Determines the water-cement ratio, crucial for strength |

| Admixture Scales | Doses small amounts of chemical additives | Modifies properties like setting time and workability |

What is the Central Mixing System?

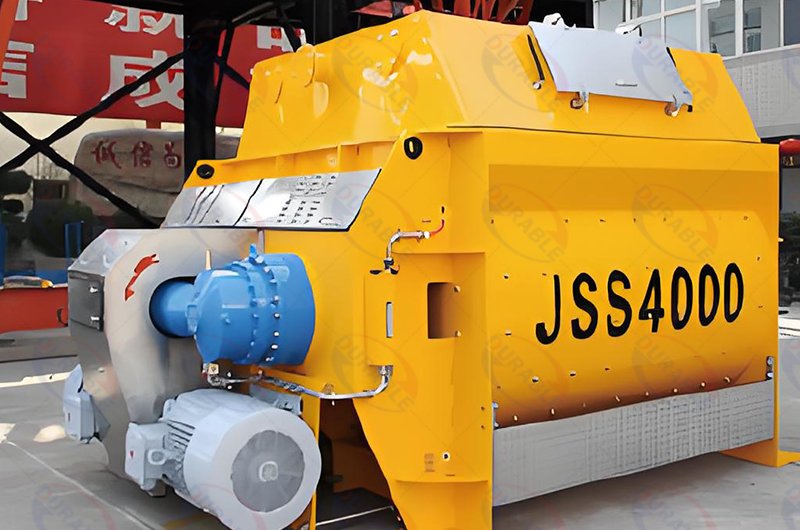

The mixing system is the heart of the entire operation. This is where the mixer finally combines all the accurately weighed ingredients to create concrete.The quality of the mixer directly determines the quality of the final product. A poor mixer can result in a non-homogenous product with inconsistent strength, even if all the ingredients were weighed perfectly.

For ready mix concrete plant applications, the industry standard is the twin-shaft concrete mixer. This type of compulsory mixer is far superior to older drum-style mixers because it forces the materials to combine through intense mechanical action.

Inside a twin-shaft mixer, two horizontal shafts fitted with mixing paddles rotate in opposite directions. This creates a highly turbulent, three-dimensional mixing action that ensures every particle of aggregate is coated with cement paste. The result is a completely homogenous and high-quality concrete mix, achieved in a very short amount of time, typically 30 to 60 seconds. This speed and efficiency are vital for high-production plants. Once the mixing cycle is complete, a large hydraulic or pneumatic gate at the bottom of the mixer opens, allowing the fresh concrete to be discharged down a chute and into the waiting transit mixer truck. The power and reliability of this mixing system are what ultimately define your plant’s capacity and product quality.

How Does the Control System Automate Everything?

The control system is the brain of the modern ready mix concrete plant, orchestrating every action with digital precision. Housed in a dedicated control room, this system is what allows a single operator to manage the entire production process. It integrates all the other concrete plant systems into one automated workflow.

The core of this system is a PLC (Programmable Logic Controller), an industrial-grade computer that physically controls all the motors, gates, and pumps throughout the plant. The operator interacts with the system through a user-friendly PC interface running specialized batching software.

From this interface, the operator can input and store hundreds of different concrete “recipes,” manage customer orders, and initiate the automatic batching sequence. Once an order starts, the control system takes over completely. It precisely opens and closes gates to weigh the exact amounts of each material, controls the conveying systems, manages the mixing time, and discharges the final product. The system monitors every step in real-time, ensuring that each batch is identical to the last. It also generates detailed reports and delivery tickets, providing crucial data for quality control and business management. This high level of automation not only ensures incredible accuracy but also maximizes plant efficiency and minimizes labor costs.

Stationary vs. Mobile Plant: Which is Right for You?

When planning your concrete plant investment, one of the first major decisions is choosing between a stationary and a mobile plant. Your choice will depend entirely on your business model and operational needs.

A stationary concrete batching plant is a large, permanent installation designed for high-volume, continuous production in a fixed location. These plants are ideal for supplying concrete to a specific city or metropolitan area. They typically offer higher production capacities, larger material storage, and more robust configurations.

A mobile concrete batching plant, on the other hand, is designed for portability. The main components are mounted on a wheeled chassis, allowing the entire plant to be transported between job sites. These are perfect for large construction projects like highways, dams, or airports, where a dedicated on-site concrete source is more efficient than hauling it from a distant location.

| Feature | Stationary Concrete Plant | Mobile Concrete Plant |

|---|---|---|

| Best For | Permanent ready-mix suppliers in a fixed market | Large, temporary construction projects |

| Production Rate | Typically higher (60-240 m³/hr) | Generally lower to medium (25-120 m³/hr) |

| Footprint | Large, requires significant civil works | Compact, requires minimal foundation preparation |

| Setup Time | Weeks to months | Hours to days |

| Flexibility | Low (permanent) | High (can be moved between projects) |

Frequently Asked Questions

Question 1: What is the most important component in a concrete plant?

While all systems are vital for the plant to function, the weighing (batching) system and the mixing system are the most critical for determining the final quality of the concrete. Accuracy in weighing and homogeneity in mixing are non-negotiable.

Question 2: How much space does a typical concrete plant require?

This varies greatly. A compact mobile plant might fit on less than half an acre, while a large stationary plant with extensive ground stockpiles for aggregates could require several acres of land.

Question 3: How long does it take to produce one batch of concrete?

With a modern, automated plant featuring a twin-shaft mixer, a complete batch cycle (weighing, mixing, and discharging) typically takes only 2 to 3 minutes. This allows for high production rates throughout the day.

Summary and Recommendations

A ready mix concrete plant is a complex integration of five core systems: storage, conveying, weighing, mixing, and control. Each system plays a critical role in the journey from raw materials to a high-quality finished product. Understanding how these concrete plant components work together is the first step in making a smart concrete plant investment. By ensuring each system is designed to meet your specific production goals, you lay the foundation for an operation that is efficient, reliable, and profitable.

At Durable Machine, we have been manufacturing and supplying concrete machinery since 2001. We provide both stationary and mobile plant solutions tailored to your project’s scale and budget. If you are ready to take the next step in your concrete plant planning, contact our team of experts today. We can help you configure the perfect system to meet your business needs.

About Durable

As a professional manufacturer of construction machinery since 2001, Durable Machine is a China-based company specializing in B2B solutions. We focus on the research, development, and production of a wide range of equipment, including complete concrete batching plants, concrete mixers, and pumps. Our facilities are equipped for excellence, allowing us to implement strict quality control at every stage of production. With products exported to over 120 countries, we are committed to providing reliable, factory-direct solutions that ensure total customer satisfaction.

Durable Machinery

Durable Machinery