Make Charcoal from Wood Waste | Compare 2 Production Lines (2025)

At Durable, we speak with business owners like you who have a valuable resource: woodworking waste. You see piles of sawdust, shavings, and offcuts, and you know there’s potential to make charcoal from woodworking waste. But this is where the critical questions begin. Should you make briquettes first? Or carbonize the waste directly? Choosing the wrong charcoal production line can be a costly mistake. This guide is your practical roadmap. We will compare the two main technological paths, helping you understand which one is the right investment for your specific situation.

Table of Contents

- Can My Sawdust, Shavings, and Offcuts Really Become Valuable Charcoal?

- Path 1: How Does the “Briquette First, Then Carbonize” Line Work?

- Path 2: What About the “Carbonize First, Then Briquette” Line?

- The Ultimate Showdown: Which Path is Better for You?

- What is the Best Solution for My Mixed Wood Waste?

- What is the Complete Equipment List and Budget?

- Will the Market Really Accept Charcoal From “Waste”?

- Can Smoke and Wood Vinegar Generate Extra Income?

- Conclusion: Your Path to a Profitable Charcoal Business

- About Durable

Can My Sawdust, Shavings, and Offcuts Really Become Valuable Charcoal?

Yes, but this is the first and most important step. You must strictly audit your raw material. Not all woodworking waste is created equal.

This is a critical safety and quality rule. Your waste falls into two categories, and the market only accepts one.

- A-Grade (Clean Waste): This is sawdust, shavings, and offcuts from natural, solid wood like pine, oak, or fruitwood. This is the perfect raw material for high-quality BBQ or industrial charcoal.

- B-Grade (Toxic Waste): This is waste from MDF, particleboard, or plywood. These materials contain glues and resins. When carbonized, these glues release toxic chemicals like formaldehyde into the charcoal. This charcoal is illegal to sell in most markets, has a terrible smell, and is completely unsuitable for any use.

Before you invest a single dollar, you must ensure your supply of woodworking waste is 100% A-Grade. If you cannot guarantee this, the project is not viable.

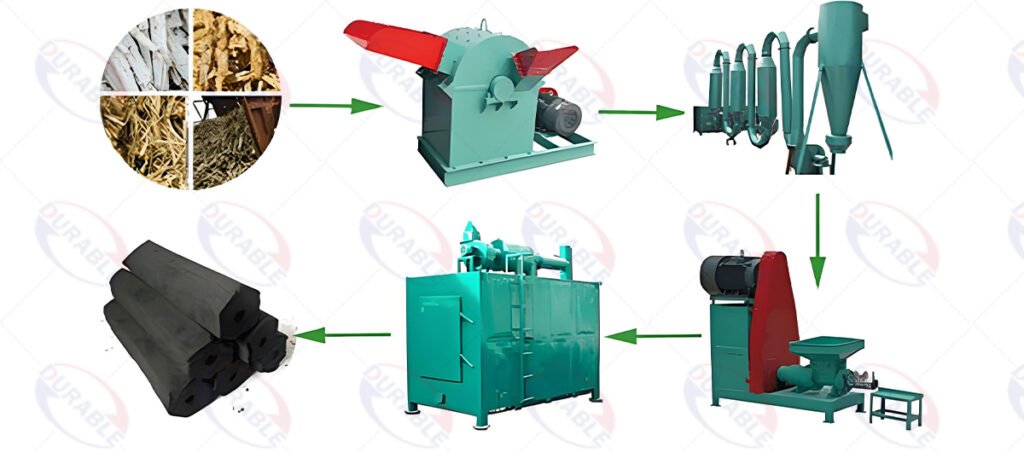

Path 1: How Does the “Briquette First, Then Carbonize” Line Work?

This is the most popular and professional method for processing fine materials like sawdust and shavings into high-quality sawdust charcoal. It is a four-step industrial system.

- Crushing: Any wood scraps larger than 6mm are first put into a hammer mill crusher. This turns everything into a uniform, fine powder.

- Drying: The powder is fed into a rotary dryer to reduce its moisture content to a precise 8-12%. This step is mandatory and consumes significant energy, but it is the key to making strong briquettes.

- Briquetting: The dry powder goes into a biomass briquette machine. This machine uses immense pressure and high temperatures (around 300°C) to melt the natural lignin in the wood, which acts as a glue. It extrudes the powder into very dense, hollow-core logs. No chemical binders are needed.

- Carbonizing: These finished briquettes are then neatly stacked inside a charcoal making machine, or carbonization furnace. They are heated in an oxygen-free environment and transformed into high-purity, uniform charcoal briquettes.

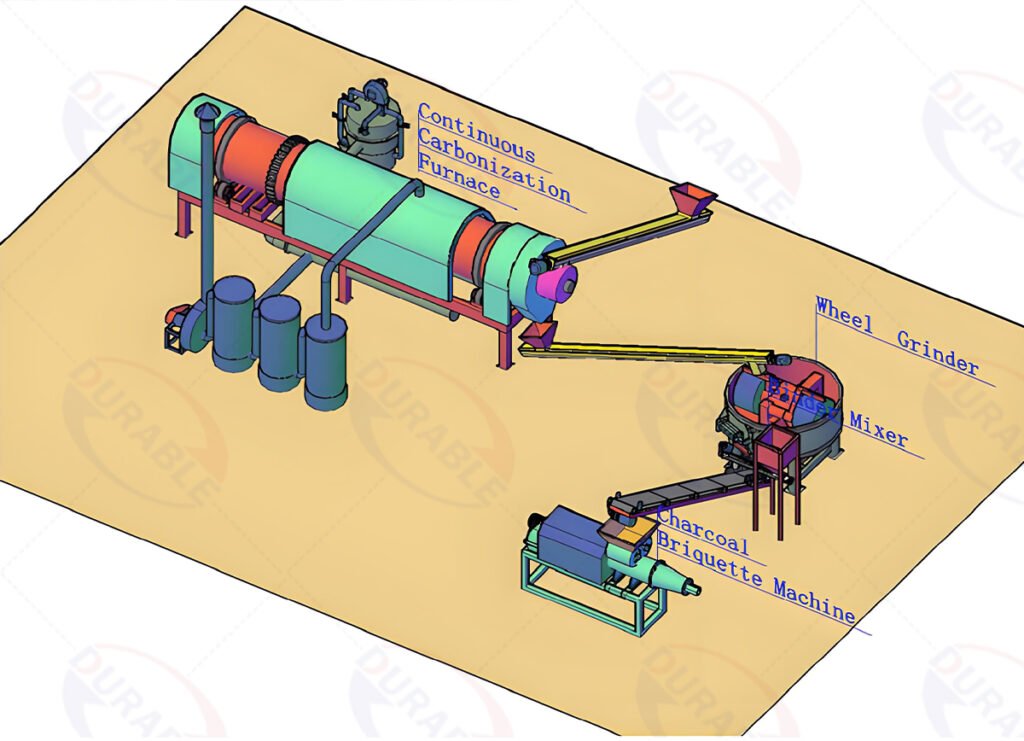

Path 2: What About the “Carbonize First, Then Briquette” Line?

This is an alternative path, often seen in smaller-scale operations. The process is reversed and involves different machinery.

- Carbonizing: The loose sawdust and small wood chips are first placed directly into a carbonization furnace. This turns the biomass into a brittle, low-density charcoal powder.

- Grinding & Mixing: The charcoal powder is then ground to be very fine. Critically, it must be mixed with a binder (like starch) and water to create a paste-like consistency. The binder is necessary because the natural lignin was destroyed during carbonization.

- Briquetting: This paste is then fed into a charcoal coal ball press machine. This machine uses rollers with molds to press the paste into pillow shapes, balls, or other small forms.

- Drying: The final, wet charcoal briquettes must be dried for 24-48 hours to remove the moisture added during the mixing stage.

This method can be cheaper to start, but the final product is generally considered lower quality due to the added binder, which can increase smoke and ash.

The Ultimate Showdown: Which Path is Better for You?

Choosing between these two charcoal production lines depends entirely on your budget, quality goals, and target market. Let’s compare them head-to-head.

| Feature | Path 1: Briquette First | Path 2: Carbonize First |

|---|---|---|

| Raw Material | Best for uniform fine powder (sawdust). | Can handle slightly more variation in initial size. |

| Binder Needed? | No. Uses natural lignin. | Yes. Requires starch or other chemical binders. |

| Final Product | High-density, high-purity, hollow-core charcoal briquettes. | Lower-density charcoal balls or pillows. |

| Best Use Case | Premium BBQ, restaurants, shisha. | Household heating, industrial fuel. |

| Process Control | High. Quality is very consistent. | Lower. Quality depends heavily on binder mixing. |

| Investment | Higher initial equipment cost. | Lower initial equipment cost. |

| Profit Potential | High. Sells at a premium price. | Medium. Competes in lower-price markets. |

Practical advice for you:

- If your goal is to produce high-quality, smokeless charcoal for the BBQ or restaurant market, Path 1 is the only professional choice.

- If your budget is extremely limited and you are targeting the local fuel market, Path 2 can be a starting point.

What is the Best Solution for My Mixed Wood Waste?

This is a common situation. Many woodworking factories produce both fine sawdust and larger, irregular offcuts and blocks. The most efficient and profitable solution is to run a hybrid system.

Do not mix them. Treat them as two separate raw material streams.

- For your sawdust and shavings: Invest in the “Briquette First, Then Carbonize” production line (Path 1). This is the best way to add value to your fine materials.

- For your wood blocks and offcuts: You do not need a briquette machine for these. You can load these directly into a modern horizontal charcoal carbonization furnace. This process will create traditional “lump charcoal,” which also has a strong market.

By separating your waste streams, you create two distinct, valuable products and maximize the profitability of your entire wood waste recycling operation.

What is the Complete Equipment List and Budget?

Planning your charcoal investment requires a clear checklist. For a professional “Briquette First” line (Path 1), your core equipment list will include:

- Raw Material Processing:

- Wood Crusher (like a hammer mill)

- Rotary Dryer System

- Core Production:

- Screw Conveyors (to move material)

- Biomass Briquette Machine

- Carbonization Furnace (hoist-type or horizontal)

- Auxiliary Systems:

- Smoke & Dust Purification System

- Cooling and Packaging Equipment

The total investment can vary widely based on capacity and automation level. However, a significant portion of your budget will be for the dryer and the carbonization furnace. These are the two most critical machines for ensuring quality and efficiency. Skimping on these will jeopardize your entire operation. The ROI charcoal production is high, but it requires a proper initial investment in robust, industrial-grade machinery.

Will the Market Really Accept Charcoal From “Waste”?

Yes, and in many cases, they prefer it. The term “waste” is misleading. You are using clean, 100% natural wood fiber.

Machine-made charcoal from a Path 1 production line is often superior to traditional lump charcoal because it is:

- More Uniform: Every briquette has the same size, shape, and density.

- More Consistent: It lights evenly and burns at a predictable temperature.

- Longer Lasting: It is denser than most lump charcoal, resulting in a longer burn time.

- Cleaner: It produces less smoke and ash, especially compared to charcoal made with binders.

Because of these qualities, your “waste-based” charcoal can be marketed as a premium product and often fetches a higher price than irregularly shaped lump charcoal.

Can Smoke and Wood Vinegar Generate Extra Income?

Yes. In a modern wood waste to energy system, nothing is wasted. The “smoke” produced during carbonization is not pollution; it is a resource.

This smoke, called syngas, is a flammable gas. A well-designed carbonization furnace will:

- Capture the Syngas: It captures 100% of the gas in a sealed system.

- Purify It: It runs the gas through condensers that extract valuable byproducts like wood vinegar (used in agriculture) and wood tar.

- Recycle It as Fuel: The cleaned, flammable gas is then piped back to the furnace and used as the main fuel source to continue the carbonization process.

This means that after the initial startup, your furnace can run with little to no external fuel. You eliminate pollution, reduce your energy costs, and create a new, sellable product (wood vinegar). This significantly improves your overall profitability.

Conclusion: Your Path to a Profitable Charcoal Business

Turning woodworking waste into “black gold” is a proven and profitable business model. Your success depends on choosing the right charcoal production line for your specific materials and market goals.

For fine materials like sawdust, the “Briquette First, Then Carbonize” path offers the most direct route to a high-quality, premium product with the best long-term profitability. While the initial investment is higher, it creates a superior product that the market values. By treating your waste as a valuable raw material and investing in a complete, integrated system, you are not just recycling; you are building a sophisticated and profitable manufacturing operation.

About Durable

At Durable, we are experts in engineering complete industrial systems. We understand that a successful charcoal making business plan requires more than just one machine; it requires a reliable, integrated line where every component works perfectly together. We provide robust, heavy-duty equipment, from crushers and dryers to advanced carbonization furnaces, designed for 24/7 operation.

Contact our engineering team today. Let’s discuss your raw materials and your vision, and we can help you design the production line that will become your path to fortune.

Durable Machinery

Durable Machinery