Search the whole station liberty-fse

QMJ2-40 Small Cement Brick Machine

Capacity:2 pieces per mould; 1440 pieces per 8 hours

Power: Diesel Engine/Electric Motor

Workers Needed: 1-2 persons

Block size: Different sizes and shapes of cement bricks/ fly ash bricks including 4inch,6inch,8inch hollow blocks, solid bricks.

Introduction:

The QMJ2-40 is a compact and affordable block-making machine, perfectly suited for small-scale industries. Despite its small footprint, this concrete bricks machine delivers exceptional efficiency and high production capacity. Requiring only 100-300 square meters for installation and just 1-2 operators, QMJ2-40 blocks machine reduces space and labor costs. This machine cement bricks can produce a variety of products, including hollow blocks, interlocking bricks, and solid blocks, making this bricks laying machine a powerful and economical solution for your business.

DM4-40 Simple Concrete Brick Making Machine

Capacity: 4-14 pieces per mould;2200-6800 pieces per 8 hours

Power: Electric Motor

Pallet size: 850*450*22mm

Moulding Method: 35-40 seconds

Introduction:

The DM4-40 manual brick making machine is an ideal solution for manufacturers seeking efficiency in a compact form. With a minimal footprint of just 2050×1660×1900mm, this brick machines fit easily into smaller workshops without sacrificing performance, consistently producing certified, high-quality bricks. Its design prioritizes ease of use, making operation and maintenance straightforward for any user. To ensure you can start production immediately, this brick making machine comes as a complete package including a concrete mixer, two trolleys, spare parts, and a free hollow block mould. For added versatility, you can effortlessly switch the mould to produce a wide variety of other brick types, making the DM4-40 a highly adaptable and cost-effective investment.

DM4-35 Easy Operation Cement Bricks Machine

Capacity: 3000-9000 pieces per 8 hours depends on your brick size

Power: 9.7KW

Forming Cycle: 35-40 Seconds

Pallet Size: 850*450*22mm

Introduction:

DM4-35 manual concrete brick making machine represents a significant step forward in performance and capability. One of the most significant upgrades is the inclusion of a materials hopper. This crucial feature allows the DM4-35 to be paired with a 6-meter conveyor belt, paving the way for semi-automated loading and making it substantially more efficient than the DM4-40. Furthermore, the machine is equipped with a powerful, electricity-driven super vibration motor. This ensures that every brick produced is of superior quality, strength, and density, meeting the highest standards for construction. For a more powerful, efficient, and quality-focused operation, the DM4-35 is the clear choice.

DM2-40 Manual Mud Brick Making Machine

Capacity: 1-2 pieces per mould; 900-1400 pieces per 8 hours

Power: no need power

Workers Needed:1-2 persons

Weight: 260KGS

Introduction:

The DM2-40 is the perfect low-cost solution for brick production, designed for complete independence and reliability. As a fully hand-operated machine, it incurs zero operating costs—no need for diesel or electricity. This makes it the ideal choice for small enterprises and regions with no or erratic power supply.

Its power lies in a robust manual lever press system, which generates an impressive 10mpa of hydraulic pressure to form high-quality, dense interlocking blocks. Built for versatility, the DM2-40 can utilize a wide range of readily available materials, including clay, mud, soil, cement, or concrete.

M7MI Mobile Interlocking Brick Making Machine

Capacity: 1-2 pieces per mould; 2500-5000 pieces per 8 hours

Power: 12HP diesel engine

Forming Cycle: 15-20 seconds

Introduction:

The M7MI, a mobile brick clay machinery engineered for ultimate mobility and on-site production. Its most outstanding feature is the complete integration of the compression chamber, a high-capacity mixer, and the diesel engine onto a single, robust trailer. This “factory on wheels” design allows this mud bricks machine to be easily towed by a tractor or a large van, bringing the entire production line directly to any project site, no matter how remote. Operating entirely on diesel power, the M7MI offers complete independence from the electrical grid and comes equipped with a generous 180-litre mixer, eliminating the need to purchase and transport separate equipment. Despite its powerful capabilities, the machine is remarkably easy to operate, requiring no advanced technical skills.

ECOBRB Clay Bricks Manufacturing Machine

Capacity:1-2 pieces per mould; 1900-3900 pieces per 8 hours.

Forming Cycle:20-25 seconds

Brick Size: Different sizes and shapes including interlocking bricks, lego bricks, etc..

Introduction:

Engineered for superior output, this ECOBRB brick press machine produces two bricks with each press, completing a full moulding cycle in just 20 seconds.This Clay brick making equipment shines through its ability to produce a wide variety of interlocking bricks in different shapes, sizes, and designs simply by swapping out the mould. To guarantee longevity and accuracy, the mould itself undergoes a specialized carburisation heat treatment, significantly increasing its surface hardness and wear resistance. Furthermore, the application of precise line cutting welding ensures a robust construction and dimensional accuracy, resulting in perfectly formed bricks every time.

Considering a manual brick making machine for your projects but unsure if it’s the right choice? Let’s explore the pros and cons to help you decide. Is a small brick making machine enough, or do you need something bigger to boost your bricks maker output? A manual brick making machine is a good option. And it is often a low-cost brick making machine. Can a hand operated brick machine meet your needs? Is a DIY brick making machine a good idea for your project? When making bricks, the making brick machine should achieve the desired output. DURABLE MACHINE provides various manual concrete block machines to meet different budgets and production goals.

Last Updated: June 2025 | Estimated Reading Time: 15 minutes

A manual brick making machine is hand-operated, producing bricks from clay or cement. It’s great where automation isn’t possible, offering a simple way to make bricks. Using a manual concrete block machine, you get quality bricks without needing electricity. A manual brick making machine is a machine for brick making powered by hand to create bricks. It’s typically used in areas where electricity is limited, and manual labor is abundant, proving useful in a variety of environments. The use of a DIY brick making machine allows builders and entrepreneurs to construct brick on a budget, making the making bricks machine an accessible option.

Key elements to understand about a manual brick making machine and what sets manual brick manufacturing machine apart from a fully automated bricks made machine:

DURABLE MACHINE provides strong manual brick machine to serve your brick making needs.

The variations available in brick machine maker models. Here are the main types of bricks machine making manually:

DURABLE MACHINE offers different types manual bricks making machines, so our machine can meet your requirements well.

Why choose manual operation for your brickwork machine?

Advantages of a manual brick compressor include low cost, simplicity of use, and independence from electricity. The low-cost brick making machine provides affordable brick on any jobsite, lowering the overall cost of brick making machine operation. A hand-operated block making machine may be just the right tool if you’re prioritizing simplicity and affordability.

Main advantages of a manual brick compressor include the making brick machine‘s simplicity and ease of use:

DURABLE MACHINE is a source supplier from China, so we can provide brick machine with low cost, and also we can design block making machine according to your request.

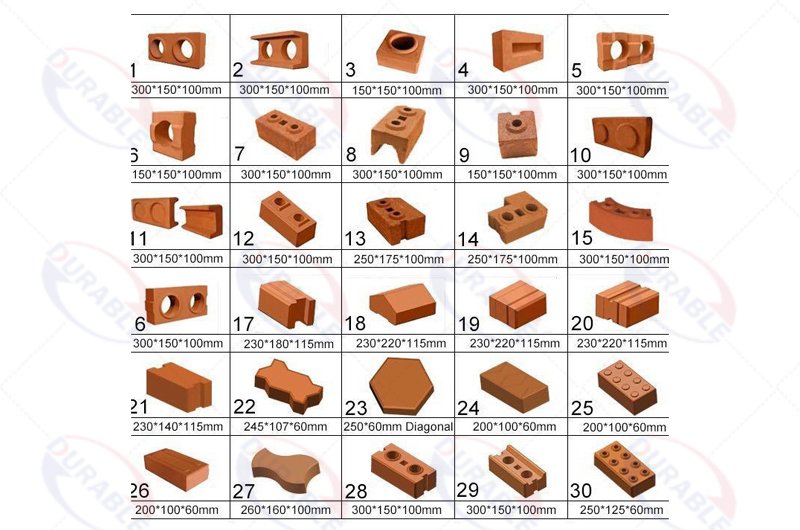

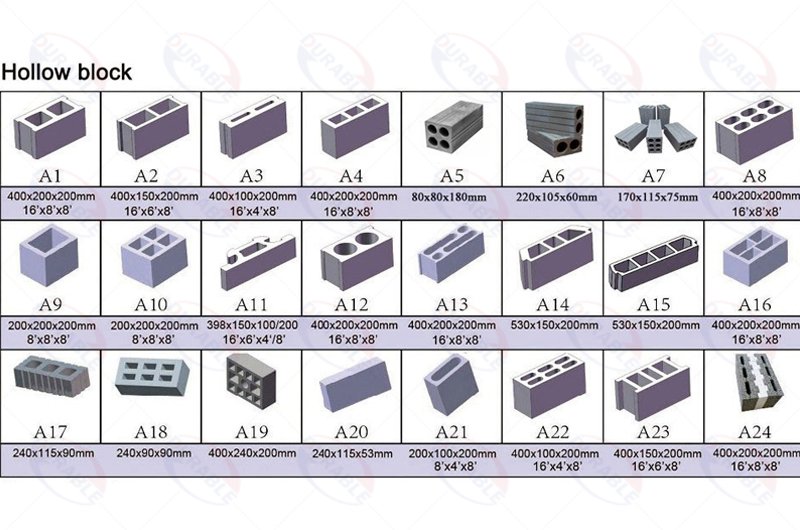

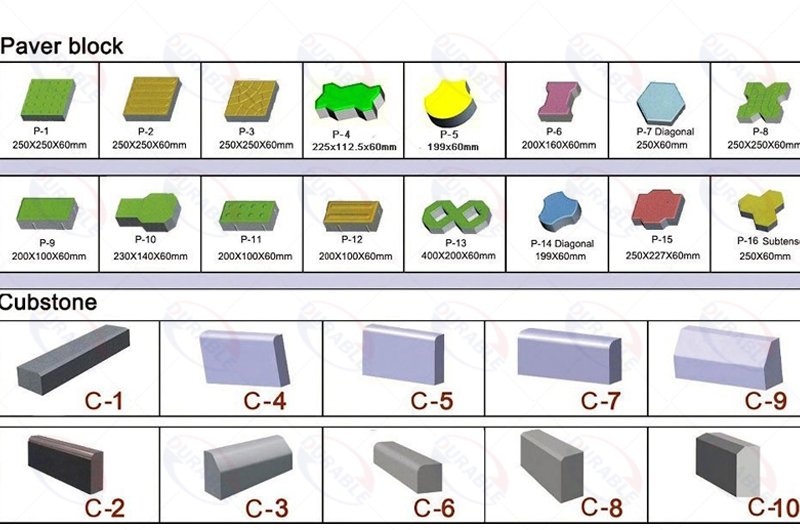

The range of possibilities with a block press machine.A manual brick block making machine can produce diverse bricks, catering to various construction needs: cement-hollow blocks, solid blocks, pavers, and kerbstones, all essential for building structures. It can also produce clay-lego bricks, solid clay bricks, and clay pavers, offering versatility in design and construction. With the right tool, you can achieve professional results with a hand-operated press, creating a wide range of brick types.

Types of bricks made by a manual brick block making machine, demonstrating its versatility:

You can give us the brick size you want to make, and as brick machine manufacturer , DURABLE MACHINE can design block mould and block machine for you.

Versatile uses in construction, achievable with your brick production machine. Blocks and bricks find uses in building walls, houses, pavements, and landscaping, showcasing their adaptability in construction projects. The brickwork machine products prove an invaluable tool in construction projects large and small, contributing to the structural integrity and aesthetic appeal of various structures.

Common applications of blocks and bricks, achievable through the consistent use of your brick manufacturing machine:

Achieving the right mix for your machine blocks. Material ratios vary significantly: Cement blocks typically use a mix of 1 part cement, 2 parts sand, and 4 parts aggregate, ensuring strength and stability. Clay bricks require a clay-rich soil mixture, often amended with sand to improve texture and firing characteristics, essential when using a clay brick making machine. The exact brick machine making process varies with the specific need and the quality of materials used.

Typical material ratios for creating quality machine bricks:

Understanding the investment in a making bricks machine.The price of a manual brick making machine ranges from a few hundred to several thousand dollars, depending on its capacity and features. Exploring a brick making machine for sale can lead to different options at various price points. You may find a cheap brick laying machine price, but more expensive models provide greater utility and longevity in production.

Cost factors for a manual brick making machine:

DURABLE MACHINE has diffent price range for brick machine. Contact us, and get the latest price. We will recommend suitable machine according to your budget. If you are looking for brick making machines for sale, consider checking Durable Machine for options. The cost of brick making machine varies based on its features and capacity.

Making the right selection in the brick making machines for sale market. To select a suitable manual block making machine, consider the type of bricks you plan to produce, the volume you need, and the machine’s durability, ensuring it aligns with your project requirements. Before purchasing a brick machine for sale in usa, take into account the price and maintenance. If the production is going to be a major enterprise, you may need more equipment for mixing and handling materials. Check out a making brick machine demonstration to help determine what equipment you will need and what it can achieve.

Key considerations for choosing a suitable manual block making machine:

When browsing brick making machines for sale in USA or elsewhere, these considerations are crucial. You will want to compare the making brick machine options to see which one will save you time and money in the long run.

Selecting a trustworthy partner for your brick machine. To find a reliable supplier for your manual brick machine, seek suppliers with good reviews, warranties, and responsive customer service, ensuring you’re purchasing from a reputable source. Purchasing a brick machine for sale from a reliable partner is a must. You want a reliable brick manufacturing machine supplier that can provide support and replacement parts when needed.

How to choose the right supplier for your brick machine:

DURABLE MACHINE has many years of experience as a brick machine maker. If you’re looking for a reliable brick machine for sale, check what Durable Machine has to offer. Ensure the brick machine maker has good reviews. Looking for a making bricks machine, ensure the supplier is credible.

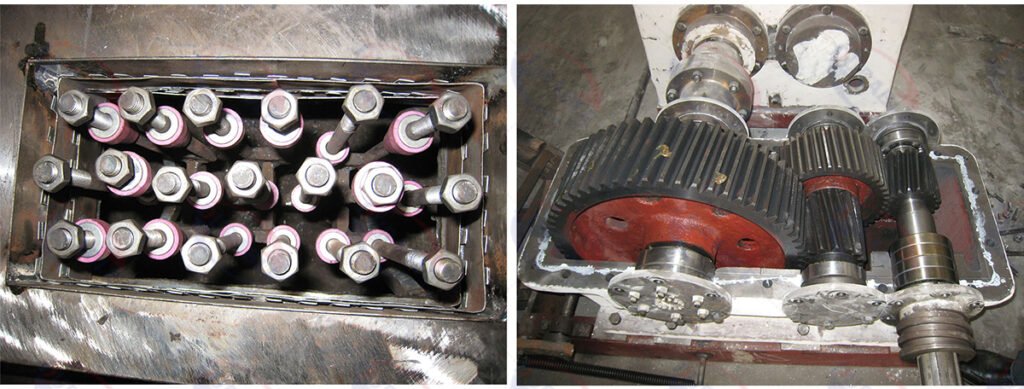

Keeping your making brick machine running smoothly. Maintenance for a manual block mould machine involves cleaning the molds regularly, lubricating moving parts, and inspecting for wear. Ensuring your making brick machine operates correctly is key. Regular maintenance of a brick machine maker product will help it operate properly and extend its lifespan. If you’re going to be relying on this heavily, regular maintenance is a must to prevent costly downtime and maintain consistent brick quality.

Essential maintenance steps for your brick making machine:

Regular maintenance ensures your bricks made machine keeps producing high-quality bricks.

Producing quality output from your brick maker.A manual brick machine makes high-quality bricks by compacting material tightly in a mold. Consistent pressure and proper material ratios are key to achieving strong, uniform bricks, suitable for construction purposes. If the brick is not well-made, it can create issues for the builder. This is the way to construct a brick maker machine operation for high-quality bricks, producing reliable building materials.

Key elements for making quality bricks with your brick maker machine:

The efficiency of the bricks making machine greatly depends on these steps.

Staffing considerations for your brick maker machine for sale. Operating a manual bricks machine typically requires 2-4 laborers for mixing materials, operating the machine, and handling the finished bricks. Accurately assess how many people will be on the jobsite to operate the brick laying machine. The exact brick production machine requirements vary based on output and the level of automation.

Typical labor requirements for a brick maker machine for sale:

Usually, a manual bricks machine needs 1-2 workers to work well. One person can use the machine, while another gets the materials ready and takes away the made bricks.

When pricing out a brick maker for sale, consider labor costs.

Manual vs. automated options available in the bricks making machine market. A manual brick making machine is less efficient and requires more labor than an automatic brick making machine, requiring more hands on the job. However, it is more affordable and suitable for small-scale production in areas with limited resources. It’s important to consider how important speed of production is for your bricks manufacturing machine goals. If you have the ability to go full automation, it could drastically improve output and efficiency, but it will also come with a higher initial cost.

| Feature | Manual Brick Making Machine | Auto Brick Making Machine |

|---|---|---|

| Cost | Costs less to start | Costs more to start |

| Production | Makes fewer | Makes more |

| Labor | Needs more workers | Needs fewer workers |

| Maintenance | Less maintenance | More maintenance |

| Complexity | Easy to use | Harder to use |

| Portability | Often can be moved | Usually stays in one place |

Comparison points for understanding the advantages of an automatic brick making machine and where a manual machine may be more appropriate:

If you are deciding between a brick manufacturing machine and a manual one, this table can help. When searching for a brick maker machine for sale, weigh these factors. The choice impacts the brick making machine price and operational efficiency.

Choose DURABLE MACHINE for your manual brick making machine needs because we offer:

DURABLE MACHINE is your supplier to help you get your brick production machine now and start making bricks! If you’re in the market for an automatic brick making machine, DURABLE MACHINE has options to consider.

Q: How many bricks can a manual brick making machine produce in a day?

A: The number of bricks produced depends on the machine’s capacity and the number of laborers involved. A typical manual brick making machine can produce anywhere from 300 to 1000 bricks per day.

Q: What materials are required to operate a manual brick making machine?

A: The materials required depend on the type of bricks you want to produce. Generally, you’ll need cement, sand, aggregate, and water for cement bricks, or clay-rich soil for clay bricks. The ratios vary based on the brick type and desired quality.

Q: Is it difficult to operate a manual brick making machine?

A: No, manual brick making machines are designed for simple operation. Minimal training is required to get started, making them accessible for various users.

Q: What is the lifespan of a manual brick making machine?

A: With proper maintenance and care, a well-built manual brick making machine can last for many years. Regular cleaning, lubrication, and inspection are key to extending its lifespan.

Q: Can I make different types of bricks with a manual brick making machine?

A: Yes, many manual brick making machines come with interchangeable molds, allowing you to produce various types of bricks, including solid blocks, hollow blocks, pavers, and more.

Q: What are the power requirements for a manual brick making machine?

A: Manual brick making machines do not require electricity, making them ideal for remote locations with limited or no access to power.

Q: Where can I purchase a reliable manual brick making machine?

A: You can purchase a reliable manual brick making machine from DURABLE. We offer a range of high-quality machines with expert support and training to help you get the most out of your investment.