Mobile vs Stationary Block Machine: An Insider’s Guide (2025)

The selection between a mobile and a stationary concrete block machine is a foundational decision that dictates a company’s production capabilities and operational framework. This choice extends beyond initial equipment cost and advertised output, requiring a thorough evaluation of site requirements, long-term operational expenditures, final product quality, and specific application suitability. This guide offers a direct, technical comparison to assist buyers in making an evidence-based investment decision aligned with their business objectives.

Table of Contents

- Operational Principles of Mobile and Stationary Block Machines

- Installation and Site Requirements for Each Machine Type

- Production Capacity and Automation of Concrete Block Machines

- Concrete Block Quality and Material Compatibility

- Total Cost of Ownership: An Economic Analysis

- Application Suitability: Mobile vs. Stationary Block Machines

- How much is the machine price?

- How to maintain the machine?

- Which factors should I consider when choosing a supplier?

- Conclusion: Make a Business Decision, Not a Machine Decision

- Why Choose DURABLE for Block Making Solutions?

Operational Principles of Mobile and Stationary Block Machines

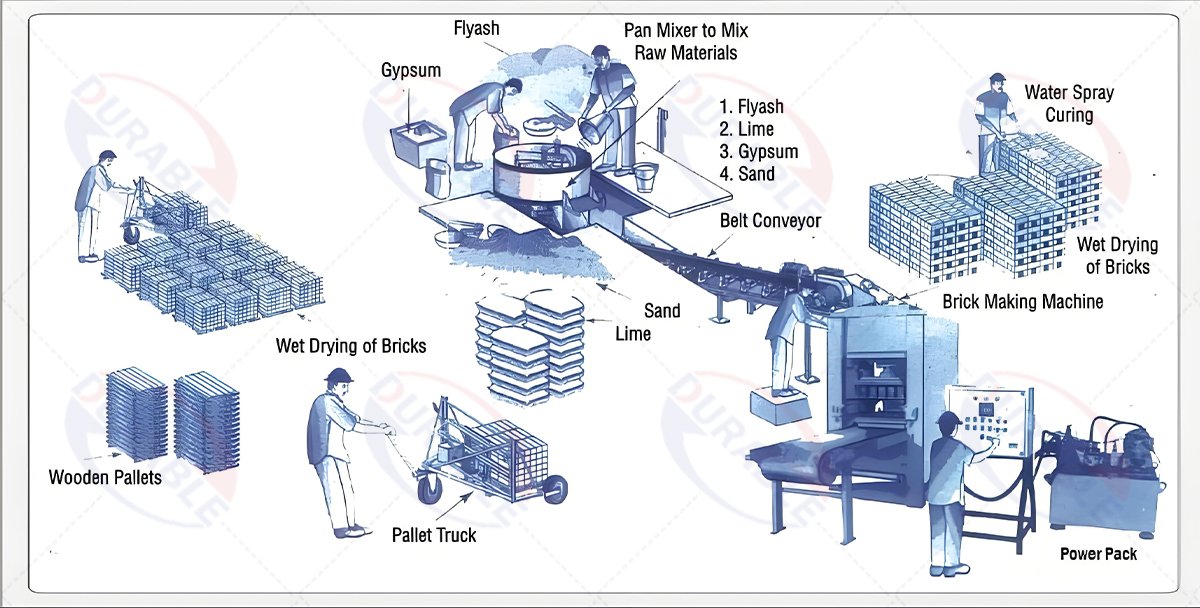

A stationary concrete block machine is the central component of an integrated production line, typically housed within a dedicated facility. This configuration incorporates automated systems for material batching, mixing, block forming, curing, and packaging. The system is engineered for continuous, high-volume manufacturing of diverse concrete products in a controlled industrial setting. A central PLC control system typically manages the entire production sequence for precision and consistency.

A mobile concrete block machine is a standalone piece of equipment designed for decentralized production directly at a construction site. It manufactures blocks on a prepared concrete floor and advances with each production cycle, leaving the newly molded blocks behind to cure. This operational method removes the requirement for production pallets but necessitates a large, unobstructed, and level area for both manufacturing and curing.

Installation and Site Requirements for Each Machine Type

The site preparation and installation for each machine type represent a primary differentiator in capital expenditure and logistics.

A mobile block machine does not require a permanent building structure, but its performance is entirely dependent on the quality of the production floor. The operation requires a large, perfectly flat, and highly durable concrete slab. The production surface itself serves as the base for the newly formed blocks, meaning any surface imperfections will directly affect block dimensions and quality, leading to a higher percentage of rejected products. Furthermore, the space must be large enough to accommodate several days of production, as blocks need to cure in place for 24-48 hours.

A stationary block machine has a more compact equipment footprint but requires the construction of a factory building or a suitable permanent shelter. This involves significant civil works, including foundations for the machine, mixer, and associated conveying equipment. The enclosed environment allows for uninterrupted, all-weather production and greater process control. The facility must also include designated zones for raw material storage, product curing, and inventory management.

Production Capacity and Automation of Concrete Block Machines

Stationary block production lines are engineered for high-volume output and scalability. A fully automatic production line can manufacture tens of thousands of concrete blocks per shift. High-level automation is a standard feature; Siemens PLC systems manage processes from aggregate weighing and water dosage to block transport and stacking. This level of control minimizes operational variance and maximizes production efficiency. DURABLE provides scalable solutions, from medium-capacity plants to large-scale industrial facilities.

Mobile block machines possess a lower production capacity. Their output is determined by the machine’s cycle time and the manual labor involved in material supply and finished product handling. Automation is limited, with operational consistency being heavily reliant on operator proficiency. These machines are effective for meeting project-specific quotas but are not structured for the continuous, high-volume manufacturing of a commercial block supplier.

Concrete Block Quality and Material Compatibility

The quality attributes of the finished concrete block are a direct result of the machine’s compaction and vibration technology.

Stationary machines produce high-density concrete blocks with superior structural characteristics. This is accomplished through a synchronized table and mold vibration system. The high-frequency vibration liquefies the concrete mixture, which facilitates the removal of entrapped air and achieves maximum material compaction. The resulting products exhibit high compressive strength, precise dimensional tolerances, and a uniform surface finish suitable for load-bearing structures and architectural applications.

Mobile machines produce standard-quality blocks for general construction. These machines typically employ a single vibration system located on the mold box. This method is sufficient for material consolidation but achieves a lower density compared to stationary systems. The blocks are appropriate for non-load-bearing walls, partition walls, and boundary fences but may not satisfy the technical specifications for high-strength structural engineering projects.

Total Cost of Ownership: An Economic Analysis

A comprehensive economic evaluation must consider the total cost of ownership (TCO) beyond the initial asset purchase.

The initial investment for a mobile block making machine is lower for the equipment itself. However, the TCO must factor in the significant expense of constructing the required high-specification concrete floor. Operational costs can be elevated due to increased labor requirements, higher potential for product rejection, and production interruptions from inclement weather.

The initial investment for a fully automatic stationary block plant is substantially higher, including the primary machine, auxiliary equipment like mixers and stackers, a large inventory of pallets, and factory construction. Conversely, the per-unit operational cost is typically lower due to automation reducing labor inputs, minimal product rejection rates (often below 2%), and consistent production schedules, resulting in greater long-term profitability.

Application Suitability: Mobile vs. Stationary Block Machines

The optimal machine choice is determined by the intended business model and application.

A mobile block machine is the indicated choice for:

- On-site Production: For large, fixed-term construction projects where producing blocks at the point of use is economically advantageous.

- Logistical Efficiency: In remote locations where raw materials are available but transport costs for finished blocks are prohibitive.

- Project-Based Operations: For contractors moving between various project sites.

A stationary block production line is the correct investment for: - Commercial Manufacturing: Establishing a business to supply a diverse catalog of concrete products to the construction market.

- Urban Market Supply: Operating in areas with consistent, high demand for quality-certified construction materials.

- Specialized Product Manufacturing: Producing premium items like architectural blocks, colored pavers, and retaining wall systems.

How much is the machine price?

This is a common question, but there is no simple answer. The price depends entirely on your needs. It is like asking, “How much does a car cost?” A simple manual machine is different from a fully automatic production line.

Here are the factors that determine the price:

- Automation Level: Manual, semi-automatic, or fully automatic. A manual block machine might cost a few thousand dollars, while a complete automatic line can be over $100,000.

- Production Capacity: How many blocks do you need to produce per day? Higher capacity means a bigger, more expensive machine.

- Block Types: Do you need to make hollow blocks, solid bricks, pavers, and curbstones? The more complex the molds, the higher the cost.

- Configuration: Do you need mixers, a batching plant, a stacker, or other supporting equipment?

As a rough guide, a small mobile machine can start from $2,000 to $10,000. A medium-sized semi-automatic stationary machine can be between $15,000 and $50,000. A large, fully automatic production line from DURABLE, including all supporting systems, typically starts from $60,000 and can go up. The best way is to talk to our experts. We can give you a precise quote based on your exact requirements.

How to maintain the machine?

Proper maintenance is the key to a long machine life and consistent block quality. It is not complicated, but it must be done regularly.

Here is a simple checklist for you:

- Daily Cleaning: After production, you must clean the leftover concrete from the mold, pressure head, and mixer. Hardened concrete is very difficult to remove and can damage the machine.

- Check and Tighten: Vibration causes bolts and nuts to become loose. Every day, you should do a quick check and tighten any loose parts, especially around the vibration motors and mold.

- Lubrication: You need to grease all moving parts according to the manufacturer’s schedule. This includes bearings, guide posts, and chains. Proper lubrication reduces wear and tear.

- Inspect the Mold: The mold is a critical part. You should check it regularly for wear. A worn-out mold will produce blocks with incorrect dimensions.

- Hydraulic System: For stationary machines, check the hydraulic oil level and temperature. Look for any leaks in the hoses. Keeping the hydraulic system clean is very important for smooth operation.

At DURABLE, we provide a detailed maintenance manual and training for your operators. Following these simple steps will ensure your investment serves you well for many years.

Which factors should I consider when choosing a supplier?

Choosing the right machine is only half the battle. Choosing the right supplier is equally important. A bad supplier can leave you with a machine that does not work and no support.

Here is what you should look for:

- Experience and Reputation: How long has the company been in business? Do they have a good reputation? DURABLE was founded in 1990. With over 30 years of experience, we understand the challenges our customers face.

- Real Manufacturer, Not a Trader: You should buy directly from the factory. This gives you a better price and direct access to technical support. DURABLE is a direct manufacturer with an 8000 square meter workshop. You are welcome to visit our factory.

- Quality of Components: Ask about the brands of key components like PLC, hydraulic systems, and motors. We use high-quality parts from brands like Siemens, Schneider, and Omron to ensure reliability.

- Customization Ability: Can the supplier design the machine and layout to fit your specific site and needs? We offer full customization services.

- After-Sales Service: What happens after you buy the machine? Do they offer installation, training, and warranty? We provide a complete service package, including sending our engineers to your country for installation and training.

Conclusion: Make a Business Decision, Not a Machine Decision

To summarize, the choice between a mobile and stationary block machine is not about which is better. It is about which is better for your business.

- Choose a mobile machine if your primary need is for temporary, on-site production for specific projects where logistics are difficult.

- Choose a stationary machine if you plan to build a long-term commercial business, selling high-quality blocks to a diverse market.

Think about your long-term goals, your budget for the entire project (not just the machine), your local labor market, and the quality standards you need to meet. This thinking will lead you to the right answer.

If you are still unsure, that’s okay. Making the right investment is a big decision. Our team of experts is here to help you analyze your needs and recommend the perfect solution, with no obligation.

Why Choose DURABLE for Block Making Solutions?

DURABLE MACHINE offers integrated block production solutions backed by over 30 years of manufacturing experience since its establishment in 1990. As a direct manufacturer with an 8,000-square-meter facility, DURABLE maintains stringent quality control over the entire production process.

The company’s comprehensive product line includes all necessary equipment for a turnkey operation, from pan mixers and conveyor systems to robotic stackers. DURABLE machines are constructed with high-wear-resistant steel and components from globally recognized brands like Siemens, Schneider, and Omron, ensuring durability and operational reliability. With equipment deployed in over 120 countries, DURABLE has the proven global experience to engineer and support production solutions for any market.

For a technical consultation and a detailed quotation based on specific project requirements, contact the DURABLE engineering team.

Durable Machinery

Durable Machinery