Pellet Making Machine

A pellet machine, also often called a pelletizer or pellet forming machine, is a piece of mechanical equipment that uses powerful physical extrusion to compress loose, low-density powdered or fragmented raw materials into high-density, uniformly shaped cylindrical pellets.

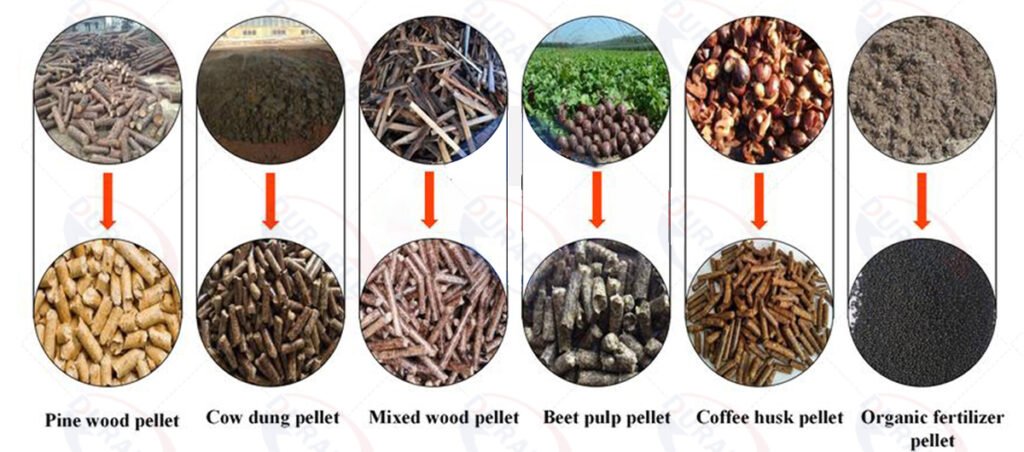

Applicable Materials:The range of materials applicable for pellet machines is very broad and can be mainly divided into two major categories: biomass fuel pellets and feed pellets.

Biomass Fuel Pellets:Sawdust,Wood Shavings,Branches,Bamboo Scraps,Waste Wood.

Agricultural Residues: Straw,Rice Husk,Peanut Shell,Sugarcane Bagasse,Palm Kernel Shell,Palm Kernel Shell.

Other Biomass:Municipal Solid Waste,Sludge,Herbal Residue, Energy Crops.

Table of Contents

- What is a Pellet Making Machine?

- What materials does a Pellet Making Machine use?

- How does a Pellet Making Machine work and what are its features?

- What other equipment is needed for a complete production line?

- How dry does my material need to be? What happens if the moisture is wrong?

- What are the advantages of pellets compared to raw materials?

- How long do the core parts (die, rollers) last? Are they expensive?

- FAQs

What is a Pellet Making Machine?

Pellet Making Machine, also often called a granulator or pellet forming machine, is a piece of mechanical equipment that uses strong physical extrusion to compress loose, low-density powdered or fragmented raw materials into high-density, regularly shaped cylindrical pellets. Its core working principle is to utilize the immense pressure and frictional heat generated by high-speed rotating rollers and a die to forcibly extrude pre-treated raw materials into the die holes for shaping. After being cut and cooled, they become solid finished products. The core purpose of this process is not only to significantly reduce the volume of the raw materials for convenient storage and transportation and to standardize their form to facilitate automated use, but more importantly, to transform low-value waste materials like wood chips and straw into high-calorific-value biomass fuel or high-nutrition animal feed, thereby achieving resource value-addition and efficient utilization.

What materials does a Pellet Making Machine use?

A pellet making machine is very versatile and can process a wide range of organic materials. The materials are generally divided into two main categories: biomass for fuel and compound ingredients for animal feed. The specific machine setup, especially the die, must be matched to the material.

For Biomass Fuel Pellets:

- Wood Materials: Sawdust, wood chips, and shavings from pine, oak, beech, and other woods are the most common.

- Agricultural Residues: Straw from wheat or rice, corn stover, rice husks, and sugarcane bagasse are widely used.

- Forestry Waste: Small branches, bark, and other residues from logging operations can be processed.

- Other Biomass: Materials like empty fruit bunches (EFB) from palm oil production, grass, and alfalfa are also suitable.

For Animal Feed Pellets:

Grains: Corn, wheat, barley, and sorghum provide energy.

- Protein Sources: Soybean meal, fish meal, and cottonseed meal are common.

- Fibers and Fillers: Ingredients like bran, alfalfa meal, and grass meal are included.

- Additives: Vitamins, minerals, and other supplements are mixed into the formula.

The key is that any material must first be ground to a consistent, fine powder before it can be successfully pelletized.

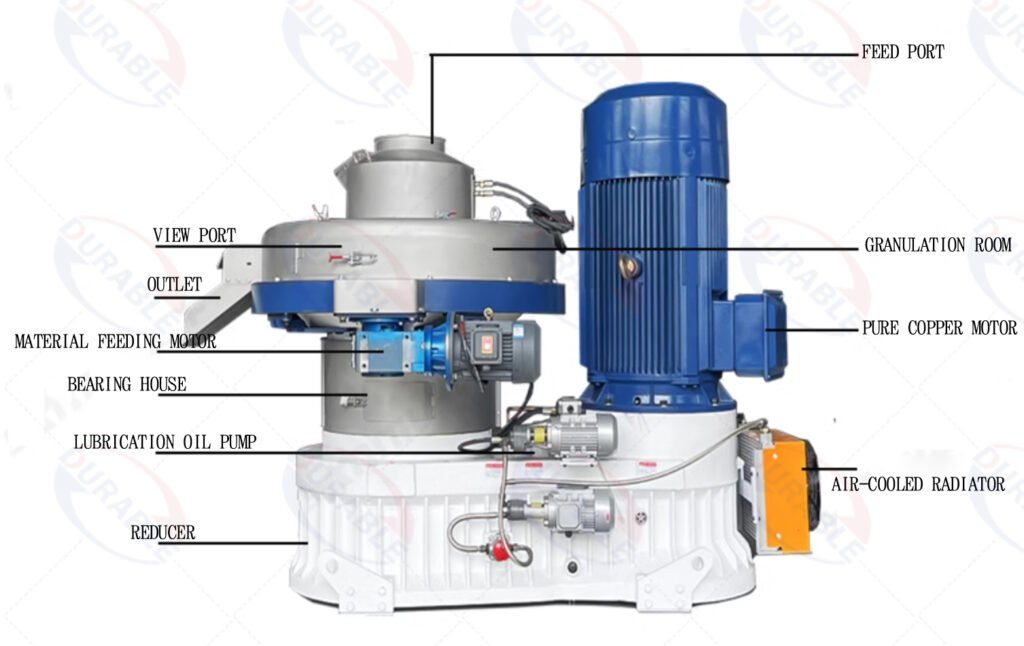

How does a Pellet Making Machine work and what are its features?

A pellet making machine works on the principle of extrusion. Finely ground raw material is fed into a pelleting chamber. Inside the chamber, rotating rollers force this material through small holes in a thick steel die. This process involves three critical actions: compression, friction, and extrusion. The immense pressure compacts the material, and the friction as it passes through the die holes generates intense heat, often reaching 80-100°C. This heat softens the natural lignin in biomass or gelatinizes the starch in feed, which then acts as a natural binder. As the compressed material is forced out of the other side of the die, a cutter knife slices it to a predetermined length, forming the final pellets.

The most critical technical feature is the compression ratio of the die. This is the ratio of the effective length of the die hole (L) to its diameter (d). This single parameter dictates the pressure and friction applied to the material.

- For Wood Pellets: You need a high compression ratio (e.g., 1:5 to 1:7) to generate enough heat and pressure to activate the lignin in wood. Using a low ratio will result in soft, crumbly pellets.

- For Animal Feed: You need a lower compression ratio (e.g., 1:10 to 1:12) to cook the starch without destroying heat-sensitive vitamins. Using a high ratio would burn the feed.

Another key feature is the gap between the rollers and the die, which must be precisely set to 0.1-0.3 mm. If the gap is too large, the rollers will slip, and production will stop. If it is too small, the metal-on-metal contact will rapidly destroy both the rollers and the die.

What other equipment is needed for a complete production line?

A pellet making machine cannot function alone. It is the heart of a larger system, and success requires investing in a complete Pellet Production Line. Each step prepares the material for the next, ensuring a high-quality final product.

The necessary equipment, in operational order, includes:

- Crushing Section: A Hammer Mill or Crusher is the first step. It takes large raw materials like wood chips, straw bales, or branches and grinds them into a uniform powder, typically less than 5mm in size.

- Drying Section: The ground material then goes to an industrial Sawdust Dryer. This machine reduces the moisture content to the optimal level for pelleting.

- Conditioning Section (Mainly for Feed): Before pelleting, feed materials pass through a conditioner. This machine injects steam to partially cook the starch, kill bacteria, and soften the material, which reduces the energy consumption of the pellet mill. For wood pellets, this step is usually not required.

- Pelleting Section: This is the pellet making machine itself, which forms the pellets.

- Cooling Section: Pellets exit the machine hot (80-90°C) and soft. A counter-flow cooler uses air to rapidly bring their temperature down. This hardens the pellets and removes excess moisture, preventing them from crumbling or molding in storage.

- Screening and Packing Section: A vibrating screen removes any fine powder or broken pellets, which are recycled back into the system. The finished, high-quality pellets are then weighed and packed into bags for sale.

How dry does my material need to be? What happens if the moisture is wrong?

The moisture content of your raw material is the single most important variable for successful pellet production. The optimal range is very narrow. For most biomass materials like sawdust and straw, the ideal moisture content is between 12% and 15%.

The consequences of incorrect moisture are severe and lead to production failure.

- If Moisture is Too High (above 15%): When the wet material enters the high-pressure die, the excess water turns into steam. This steam creates back-pressure inside the die holes, preventing the material from compacting properly. The result is frequent die blockages, or “jams.” If any pellets are produced, they will be soft, have a rough surface, and will easily fall apart after cooling. The machine will be unable to run continuously.

- If Moisture is Too Low (below 12%): The material lacks the necessary lubrication that water provides. This causes extreme friction between the material and the die. The energy consumption of the machine will increase dramatically, and the temperature inside the die can become too high. This leads to very low output, as the material will not flow smoothly. It also causes rapid, premature wear on the die and rollers, significantly increasing your operational costs. The pellets may look scorched or burnt.

Therefore, investing in an accurate moisture meter and a reliable industrial dryer is not optional; it is essential for consistent operation.

What are the advantages of pellets compared to raw materials?

Converting loose raw materials into pellets provides significant, measurable advantages in handling, storage, and energy efficiency. The primary benefit comes from a dramatic increase in bulk density.

Loose sawdust has a bulk density of about 150-200 kg/m³. After being processed by a pellet making machine, the resulting wood pellets have a bulk density of 600-700 kg/m³. This four-fold increase in density creates several key advantages:

Reduced Transportation and Storage Costs: You can transport four times the amount of material (by weight) in the same truck volume. This drastically cuts logistics costs. Similarly, you need only one-quarter of the warehouse space to store the same amount of energy.

- Improved Handling and Automation: Pellets are uniform, small, and flow like a liquid. This makes them ideal for use in automated feeding systems for industrial boilers or residential stoves. Raw biomass is irregular and cannot be easily automated.

- Higher Energy Density and Efficiency: Because they are so dense and have low moisture, pellets burn much more consistently and completely than raw biomass. This results in higher thermal efficiency and less ash.

- For Animal Feed: Pelleting prevents animals from selectively eating only the ingredients they prefer, ensuring they receive a balanced diet with every bite. The heat process also gelatinizes starches, making them easier to digest, and kills harmful bacteria like salmonella.

How long do the core parts (die, rollers) last? Are they expensive?

The ring die and the rollers are the primary wear parts of a pellet making machine. They are expensive, and their lifespan is a major factor in your production cost per ton. Their durability depends on two things: the quality of the steel they are made from and the abrasiveness of the material you are processing.

The material of the die is critical.

- For Wood Pellets: Because of the high pressure and abrasion, the die must be made from high-quality alloy tool steel (like 20CrMnTi). It must undergo a specialized heat treatment process, including carburizing and quenching, to achieve a very high surface hardness (HRC 58-62) while keeping the core tough. A low-quality steel die will wear out very quickly.

- For Feed Pellets: The die is typically made from high-chrome stainless steel (like X46Cr13) to prevent corrosion and ensure food safety.

The manufacturing process also matters. High-quality dies are drilled using a gun drilling process, which creates extremely smooth holes. This reduces friction and extends the die’s life.

A high-quality alloy steel die processing clean pine sawdust might last for 800-1,000 tons. The same die processing rice husks, which are very high in abrasive silica, might only last for 200-300 tons. The roller shells have a similar lifespan. While these components represent a significant initial cost, investing in high-quality, properly manufactured parts results in a much lower cost per ton over the life of the machine.

FAQs

Q1: What is the difference between a flat die and a ring die pellet mill?

A: A flat die pellet mill has a stationary, flat die and rotating rollers that press material downwards. It is simpler and best for small-scale production. A ring die pellet mill has a rotating, vertical die and stationary rollers that press material outwards. It is more efficient and durable, making it the standard for industrial production.

Q2: Why do I need to “run-in” a new die before production?

A: A new die has microscopic burrs inside the holes from the drilling process. You must polish these holes by running a special mixture of oil, bran, and fine sand through the mill for several hours. If you skip this step, the material will stick inside the holes, and the die will immediately block, or “jam.”

Q3: Can I make both wood pellets and animal feed with the same machine?

A: You can use the same machine body, but you absolutely must use a different die. Wood pellets require a high compression ratio die to generate heat and pressure for lignin. Animal feed requires a low compression ratio die to cook the ingredients without destroying nutrients. Using the wrong die will result in complete production failure.

Q4: What is the most common cause of a pellet mill blocking?

A: The most common cause is incorrect moisture content in the raw material. If it is too wet, it will turn to steam and block the die. Other causes include material that is not ground finely enough or an incorrectly set gap between the rollers and the die.

Q5: Do I need a conditioner to make wood pellets?

A: Generally, no. A conditioner, which adds steam, is primarily used for making animal feed to help gelatinize starch. For wood pellets, the high pressure and friction inside a die with the correct compression ratio are sufficient to activate the natural lignin binder.

Durable Machinery

Durable Machinery