Profit from Waste: How to Build a Sustainable Briquetting Plant

You are considering a briquetting plant investment, a smart move in today’s world of rising energy costs and focus on recycling. But turning this investment into a profitable business is more than just buying a machine. At Durable, we have helped build hundreds of plants worldwide. We know that a successful plant operates like a complete ecosystem, not just a collection of equipment. The success of your project is decided long before you purchase the first machine. This guide will provide you with the ultimate briquetting plant business plan, showing you how to maximize profit by making the right decisions from day one.

Table of Contents

- What is the Market Demand and Profit Potential for Finished Briquettes?

- Which Raw Materials Can Be Briquetted, and How Do You Assess Their Cost and Stability?

- What Are the Core Processes and Equipment in a Complete Briquetting Line?

- How Do You Select the Right Briquetting Machine and Ancillary Equipment?

- How Do You Plan the Plant Layout for Maximum Production Efficiency?

- How to Structure the Total Investment Budget for a Briquetting Plant?

- What Common Investment “Traps” and Operational Risks Must You Avoid?

- How to Effectively Communicate with a Supplier to Get a Custom Solution and Accurate Quote?

- FAQ

- Conclusion: Your Success is in the System

- About Durable

What is the Market Demand and Profit Potential for Finished Briquettes?

The market for briquettes is large and growing. This is driven by two key factors: the rising cost of traditional fuels and the global push for sustainable energy and waste recycling. Briquettes are used as a fuel source in industrial boilers, power plants, and for heating. Specific types, like charcoal and mineral briquettes, are essential for processes like steelmaking, silicon metal production, and even for the consumer BBQ market. Your briquetting plant profit analysis begins by understanding this demand.

The profitability of your plant is a simple but powerful equation: (Selling Price per Ton of Briquettes) – (Total Cost per Ton to Produce) = Profit per Ton. The selling price is set by your local market. Your job is to minimize the production cost. This includes the cost of raw materials, labor, energy, and maintenance. A well-designed low-cost briquetting plant focuses relentlessly on keeping these operational costs down. For example, turning a waste product that costs you almost nothing into a briquette that sells for $100-$200 per ton creates a massive profit margin.

| Briquette Type | Common Uses | Profit Potential | What This Means For You |

|---|---|---|---|

| Biomass/Wood Briquettes | Industrial boilers, heating, power plants | Medium to High | You can turn cheap agricultural or wood waste into a valuable, eco-friendly fuel. |

| Charcoal Briquettes | BBQ, metallurgy, chemical industry | High | This is a value-added product. It requires an extra carbonization step but commands a much higher price. |

| Coal/Coke Briquettes | Steel mills, home heating, industrial fuel | Medium | You can utilize fine coal dust, a cheap waste product from mining, and turn it into a uniform fuel. |

| Mineral Powder Briquettes | Steelmaking (iron ore, mill scale), metallurgy | High | This process reduces waste and makes handling and transport of mineral fines much more efficient. |

Which Raw Materials Can Be Briquetted, and How Do You Assess Their Cost and Stability?

Your business is not “making briquettes.” Your business is “managing waste within a 50-kilometer radius.” This is the single most important concept for your briquetting plant investment. Most failed projects make the same mistake: they buy the machine first and then look for raw materials. The cost and availability of your raw material will determine your plant’s success or failure.

Before you even request a quote for a machine, you must map out all potential raw materials for briquetting near your proposed plant location. Transportation is a major profit killer. If your material source is too far, the shipping cost per ton can eliminate your entire profit margin, especially for low-density materials like sawdust. You need a stable, long-term supply of low-cost material.

Practical advice for you:

- Identify Sources: Look for furniture factories (sawdust), wood processing plants (shavings), farms (straw, stalks), and mines (coal dust, mineral fines).

- Assess Quantity & Stability: How many tons can they supply per month? Is it available year-round, or is it seasonal?

- Calculate “Landed Cost”: The real cost is the price of the material PLUS the cost to transport it to your factory gate.

- Test the Material: Not all materials are the same. The moisture content, particle size, and composition will affect your process. Always get a sample and have it tested. For materials like coal and minerals, you will also need to consider a binder. Learn more about our Charcoal & Coal Ball Press Machine to see how it handles different materials.

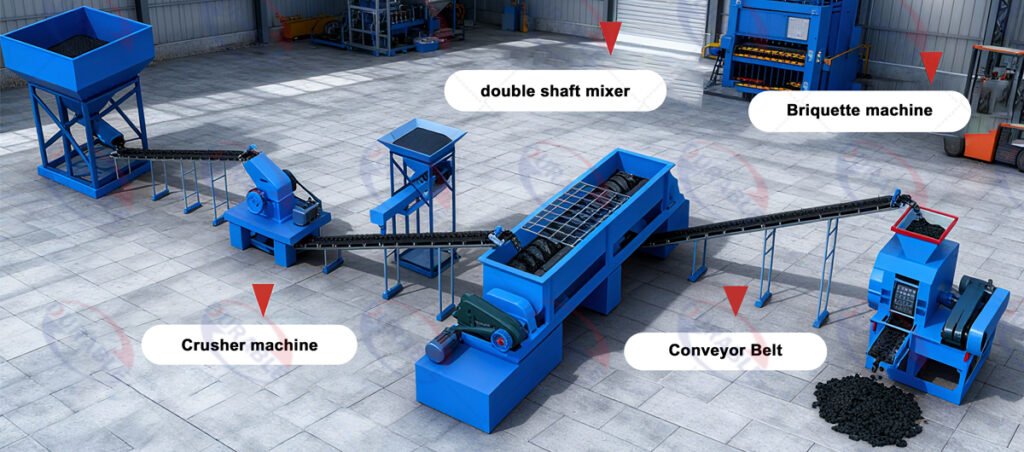

What Are the Core Processes and Equipment in a Complete Briquetting Line?

A complete briquetting process flow is a system where each machine prepares the material for the next. The final output quality depends on every single step being done correctly. Skipping a step to save money is the fastest way to guarantee failure.

The typical process includes:

- Crushing: If your raw material is too large (e.g., wood branches, large coal lumps), it must first be crushed into a smaller, uniform size. A hammer crusher is often used for this.

- Drying: This is the most critical step. Most materials need to have their moisture content precisely controlled. A rotary dryer is the heart of the production line, acting as a “process stabilizer.” It ensures that no matter what the initial moisture is, the material going into the briquette machine is perfect every time.

- Mixing: For materials that require a binder (like coal or mineral powders), a mixer is used to evenly distribute the binder and water throughout the material.

- Briquetting: This is where the magic happens. The prepared material is fed into the briquette machine, which uses immense pressure to form the final product.

- Drying/Cooling: The freshly pressed briquettes are often hot and may need to be cooled. Briquettes made with a binder will need to go through a final drying process to gain their full strength.

How Do You Select the Right Briquetting Machine and Ancillary Equipment?

You must invest for “balanced capacity,” not “peak capacity.” A common mistake is buying a 1 ton-per-hour briquette machine but only a 0.5 ton-per-hour dryer. The production line’s actual output is always limited by its slowest machine—the bottleneck.

You must design your line backward from your target output.

- Your Goal: To produce 1 ton of finished briquettes per hour.

- Briquette Machine: You will need a briquette machine selection with a capacity of 1 ton per hour.

- Dryer: To get 1 ton of dry material, you might need to feed in 1.5 tons of wet material (depending on initial moisture). Therefore, your dryer needs to have a capacity of at least 1.5 tons per hour.

- Crusher: Similarly, your crusher must be able to supply the dryer with at least 1.5 tons of raw material per hour.

Under-sizing your preparation equipment (crusher and dryer) to save money is the most common reason why a plant never reaches its designed capacity. It guarantees that your expensive briquette machine will be “starving” and operating inefficiently. For high-volume production, a complete charcoal briquetting plant setup is essential.

How Do You Plan the Plant Layout for Maximum Production Efficiency?

Your factory layout is an “invisible operational cost.” A poor layout increases labor costs, energy consumption, and maintenance time. A great briquetting plant layout makes your operation smooth, safe, and efficient.

Think about the “flow” of your plant:

- Material Flow: The path from raw material storage to the finished product warehouse should be as straight as possible. Every turn, every extra conveyor, is an additional cost and a potential point of failure.

- Personnel Flow: Operators need safe and easy access to all machines for operation and routine checks.

- Maintenance Access: You must leave enough space around each machine for repair and maintenance. Trying to save space here will cost you dearly in extended downtime when a repair is needed.

- Buffer Silos: A smart layout includes small storage silos between the main processing stages (e.g., between the dryer and the briquette machine). These “buffers” act as shock absorbers. If the crusher needs to stop for 10 minutes to change a blade, the buffer silo can keep feeding the briquette machine, so the entire line doesn’t have to stop.

How to Structure the Total Investment Budget for a Briquetting Plant?

Your briquetting plant cost budget is much more than just the price of the machines. A realistic budget is essential for a successful briquette plant project report.

Here is a typical breakdown of costs:

- Equipment Costs (50-60%): This includes the main machines (crusher, dryer, briquette press) and ancillary equipment (conveyors, silos, dust collectors).

- Site and Civil Works (20-25%): This covers the cost of the land (if purchased), factory building, foundations for the machines, and storage areas.

- Installation and Commissioning (5-10%): The cost of having engineers install the equipment and get the plant running correctly.

- Utilities (5%): Cost to bring sufficient electrical power to the site.

- Working Capital (10-15%): The money you need to have on hand to buy initial raw materials, pay salaries, and cover other operational costs before you start generating revenue.

What Common Investment “Traps” and Operational Risks Must You Avoid?

Before you launch your project, be aware of the common briquetting plant risks. Acknowledging them is the first step to mitigating them.

Here is your risk checklist:

- The Raw Material Trap: Falling in love with a machine before securing a stable, long-term, low-cost raw material supply. This is the #1 killer of new plants.

- The “Skip a Step” Trap: Trying to save money by not buying a crusher or a dryer. This will result in poor quality briquettes and an unreliable production line.

- The Undersizing Trap: Buying preparation equipment (dryer, crusher) that is too small for your briquette machine, creating a permanent bottleneck.

- The Wear Parts Trap: Forgetting that parts like propellers, rollers, and molds wear out. You must budget for their repair and replacement. Mastering the repair of these parts is a core skill for a profitable plant.

- The Environmental Trap: Ignoring dust and smoke emissions. Modern plants must have proper dust collection and emission control systems to operate legally and responsibly.

How to Effectively Communicate with a Supplier to Get a Custom Solution and Accurate Quote?

To get the best solution from a briquette machine manufacturer like us, you need to provide clear and detailed information. This allows us to design a plant that perfectly fits your needs and gives you an accurate price.

When you contact us, be prepared to answer these questions:

- What is your raw material? (e.g., sawdust, coal dust, iron ore fines)

- What is the initial size and moisture content of your material?

- What is your target production capacity? (in tons per hour)

- What is the final shape and size of the briquettes you want to make?

- What is the intended use of your final briquettes? (e.g., for fuel, for metallurgy)

- Do you have a factory building already? What are its dimensions?

Providing this information will help us move quickly from a general discussion to a concrete, customized proposal for your briquetting plant investment.

FAQ

Question 1: What is the estimated ROI for a briquetting plant?

The Return on Investment (ROI) varies greatly depending on your local raw material cost and the selling price of briquettes. However, because you are often turning low-value waste into a high-value product, many well-run plants can achieve an ROI in as little as 12-24 months.

Question 2: Do I always need a binder for my briquettes?

It depends on your raw material. Biomass materials like wood and straw contain natural lignin, which acts as a binder when heated. For materials without lignin, such as coal, charcoal, and mineral powders, you will need to add a binder (like starch, molasses, or sodium silicate) to ensure the briquettes are strong.

Conclusion: Your Success is in the System

A successful briquetting plant investment is not about having the single best machine; it is about creating the most efficient and balanced system. Your success starts with a deep understanding of your local raw materials and market. It is secured by investing in a complete and properly sized production line, with a special focus on the often-underestimated crushing and drying stages. And it is sustained by a smart plant layout and a proactive approach to maintenance. By thinking of your plant as an ecosystem, you move from just being an equipment owner to being a strategic producer, ready to turn waste into wealth.

About Durable

At Durable, we do more than just sell equipment. We are your partners in production. With over 20 years of experience, we have engineered and installed complete briquetting and processing plants across the globe. We use our expertise to help you plan, build, and operate a plant that is not just functional, but highly profitable and sustainable. Our direct-from-factory model ensures you get the best value, and our full-service support means we are with you every step of the way.

Ready to turn your vision into a profitable reality? Contact our team of expert engineers today for a customized solution and a detailed quote.

Durable Machinery

Durable Machinery