Profitable Charcoal Production: Airflow Carbonization

I have seen many changes in mineral processing and biomass handling over the years. I know “carbonization” is more than just a physical change. It turns waste into useful products. The Airflow Hoisting Carbonization Furnace charcoal making process is a modern way to do this. This article will explain how it works. I will cover its principles, its process flow, and where it can be used. This information will help you understand this important technology.

Table of Contents

- How is the airflow hoisting carbonization process different from traditional methods?

- How does biomass raw material pretreatment affect carbonization efficiency?

- What is the role of airflow hoisting technology in raw material conveying?

- What happens during raw material drying, preheating, and deep carbonization inside the furnace?

- How are combustible gases produced during carbonization recycled and reused?

- What are the methods for cooling and discharging finished charcoal?

- How are carbonization tail gases purified to achieve compliant emissions?

- How are smart systems used to control carbonization temperature, airflow, and time parameters?

- How do we adjust carbonization process parameters for different biomass raw materials?

- How does the airflow hoisting process affect wood charcoal’s fixed carbon and ash content?

- How does the airflow hoisting carbonization process ensure production safety?

- What are the benefits of airflow hoisting charcoal making technology for production operations?

- FAQs

- Conclusion

- About Durable

How is the airflow hoisting carbonization process different from traditional methods?

The airflow hoisting carbonization process is very different from old ways. Many traditional methods often burn biomass directly. This causes a lot of smoke and pollution. They are also usually batch processes. This means they stop and start. The airflow hoisting method is much cleaner and more efficient. It is a type of continuous carbonization process.

Traditional methods use direct heating. Fires touch the biomass. This can cause uneven heating. Some biomass burns instead of turning into charcoal. This reduces the charcoal yield. It also releases much smoke and tar. This is bad for the environment. My experience shows these older ways are harder to control. The airflow hoisting carbonization furnace uses indirect heating. Hot gases do not touch the biomass directly. Instead, they circulate around a sealed inner tank. This heats the biomass in an oxygen-free space. This is very important. It ensures the biomass breaks down into charcoal, gases, and liquids without burning. This indirect heating makes carbonization more uniform. It leads to a higher yield of high-quality charcoal production.

The “airflow” here has two main jobs. It helps with auto-ignition. It also helps with efficient heat transfer. This makes the carbonization process self-sustaining. The system also recycles gas. Traditional methods often release smoke into the air. This furnace captures combustible gases. It burns them to provide heat for the process itself. This makes the system more energy efficient. It is an eco-friendly charcoal making process. The “hoisting” part also means we can move tanks in and out. This makes it more like a continuous process. It is not a simple batch system.

How does biomass raw material pretreatment affect carbonization efficiency?

Biomass raw material pretreatment is very important for carbonization. It greatly affects how well the furnace works. It also impacts the quality of the charcoal. If you skip this step, your carbonization efficiency will be low.

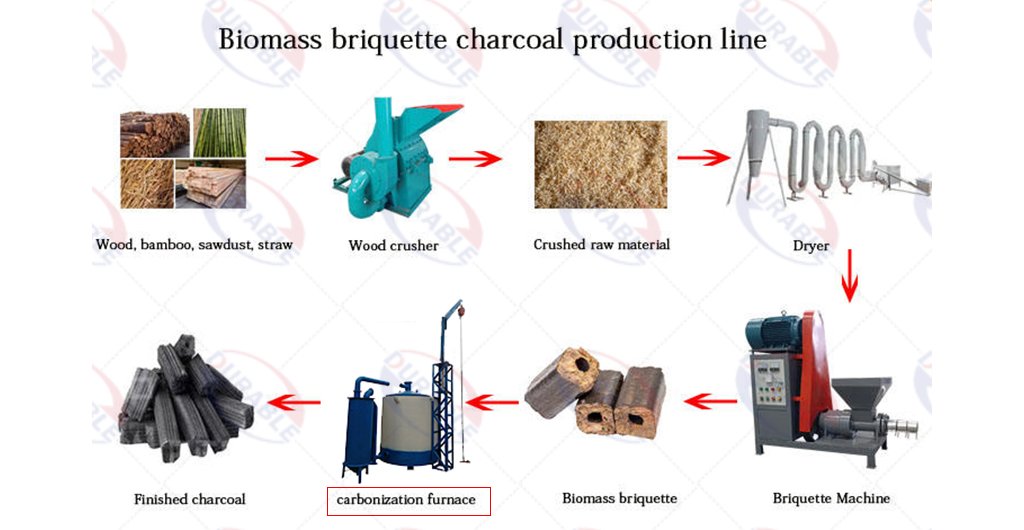

First, moisture content is vital. Biomass often contains much water. If raw material is too wet, the furnace must use energy to dry it first. This wastes much heat. It also makes the whole process longer. This increases your costs. I have seen that ideal moisture content for most biomass should be below 15%. Often, 10-12% is best. You can use a dryer, like a wood chips dryer or a sawdust dryer, to get the right moisture.

Second, particle size also matters a lot. Biomass needs to be a consistent size. If pieces are too big, they will not carbonize evenly. The outside might char, but the inside stays raw. If pieces are too small, they can pack too tightly. This can block gas flow. This makes it hard for heat to spread. A hammer mill crusher can reduce biomass to a uniform size. This includes wood scraps or agricultural waste. Sometimes, materials like sawdust need to be pressed into briquettes or pellets. This makes them denser. This allows for better heat transfer and more efficient carbonization. Proper pretreatment is a key step for raw material pretreatment for charcoal. It sets the stage for a successful charcoal making process flow.

What is the role of airflow hoisting technology in raw material conveying?

The term “airflow hoisting” in this furnace mainly refers to the heating method. It describes how hot gas circulates to heat the carbonization tanks. However, the “hoisting” part also refers to how raw material conveying is made efficient. This uses detachable carbonization tanks. This is part of the overall charcoal making process flow.

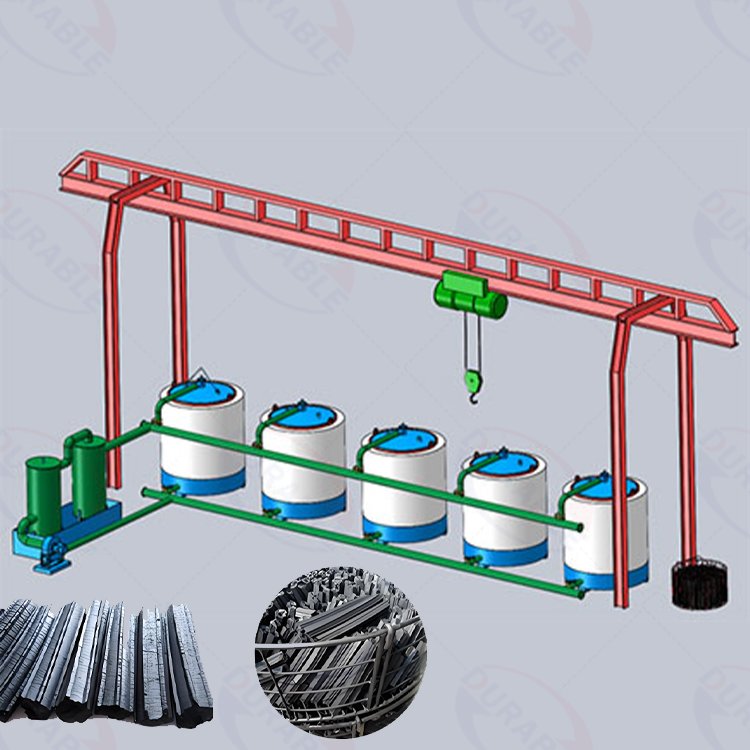

This system usually has one main heating furnace. It uses several removable inner tanks. These tanks hold the biomass raw material. After preparing the raw material, we load it into these tanks outside the furnace. Then, a crane or a lifting mechanism lifts these loaded tanks. It then lowers them into the main heating furnace.

Once carbonization is done, the same mechanism lifts the hot tanks out. It moves them to a cooling area. While one tank is carbonizing, another can be cooling. A third tank can be loading new raw material. This system allows for a continuous flow of batches. It uses mechanical hoisting to move large batches of raw material in tanks. This makes the continuous carbonization process possible. It saves time and allows for efficient material handling. This is how the “hoisting” aspect supports airflow hoisting conveying. It helps maintain a smooth production cycle. This is different from systems that move loose material.

What happens during raw material drying, preheating, and deep carbonization inside the furnace?

Inside the airflow hoisting carbonization furnace, raw material goes through three main stages. These are drying, preheating, and deep carbonization. These stages are key for the charcoal making process flow. They ensure biomass turns into high-quality charcoal. I have seen that controlling each stage well is vital.

First is the Drying Stage. When we put the loaded tank into the furnace, the raw material still has moisture. The furnace temperature starts to rise. In this first stage, usually around 100-200°C, the main goal is to remove water. Water turns into steam and leaves the tank. It is important for temperature to rise slowly here. If it rises too fast, water inside the biomass turns to steam too quickly. This can make biomass crack or even break apart. This hurts charcoal quality.

Second is the Preheating Stage. As temperature goes up to 200-350°C, biomass starts to break down chemically. This is pyrolysis. It starts to release some gases and tar vapor. These gases are often combustible. This stage prepares the material for final carbonization. It also starts to produce gases that can be recycled for heat.

Third is the Deep Carbonization Stage. This is the most important stage. Temperature rises further, typically to 350-600°C, or sometimes even higher. At these temperatures, most organic matter in biomass breaks down. It releases much combustible gas and tar vapor. What is left is mostly fixed carbon, which is charcoal. Higher temperatures in this stage lead to higher fixed carbon content in the charcoal. This means better quality charcoal. But very high temperatures can slightly reduce the total amount of charcoal you get. This three-stage process ensures high-efficiency biomass charcoal making.

How are combustible gases produced during carbonization recycled and reused?

One of the best features of the airflow hoisting carbonization process is its ability to recycle gases. It reuses the combustible gases that are made during carbonization. This is a very important part of its charcoal making energy-saving technology. It also makes it an eco-friendly charcoal making process.

As biomass heats up inside the sealed inner tanks, it undergoes pyrolysis. This process breaks down organic material. It releases several types of gases. Some of these gases are non-condensable. They are also highly combustible. These are often called syngas or biomass gas. In traditional carbonization, these gases were often just vented into the atmosphere. This caused pollution. Our system collects these gases. It directs them through a pipe system. These gases then go into a secondary combustion chamber. This chamber is usually located outside the main heating furnace body.

Inside this chamber, the combustible gases mix with a controlled amount of air. They are then ignited. This creates a powerful, high-temperature flame. This flame provides the heat needed to warm the main furnace body. This heat then transfers to the carbonization tanks inside. This means that after initial startup heat, the carbonization process becomes self-sufficient. It uses its own generated gases as fuel. This significantly reduces the need for external energy. It cuts down on operating costs. It also eliminates the release of these gases into the air. This makes the entire process much cleaner and more sustainable. This is a core part of exhaust gas recycling carbonization.

What are the methods for cooling and discharging finished charcoal?

After the deep carbonization stage, finished charcoal is still very hot. Proper cooling and discharging are essential. This ensures the charcoal maintains its quality. It also ensures safety. This is a critical step in the charcoal making process flow.

Once carbonization is complete, the inner tank holding the hot charcoal is lifted out of the main heating furnace. This uses the “hoisting” technology. The hot tank then moves to a cooling area. It is very important that the tank remains sealed during this time. Hot charcoal will ignite immediately if it touches air. This would turn the charcoal back into ash.

Most systems use natural cooling. The sealed tank simply cools down slowly in the open air. This can take several hours. Some advanced systems use water cooling. This circulates water around the outside of the sealed tank. This speeds up cooling. Once the charcoal cools to a safe temperature, usually below 50°C, it is ready for discharge. The charcoal is then carefully unloaded from the tank. This can be manual or automated. During discharge, ensure good ventilation in the area. This helps disperse any remaining gases or dust. Operators must wear proper safety gear. This careful cooling and discharge process helps produce high-quality charcoal production.

How are carbonization tail gases purified to achieve compliant emissions?

Achieving compliant emissions is a top priority for any modern charcoal making process. The Airflow Hoisting Carbonization Furnace uses methods to purify its tail gases. This makes it an eco-friendly charcoal making process. I have seen how important this is for environmental rules.

During carbonization, biomass breaks down. It produces various gases. We recycle combustible gases for heat. But after these gases burn, some non-combustible gases and fine particles remain. These are the “tail gases” that need treatment. These gases leave the secondary combustion chamber. They go through a purification system.

One common method uses a dust collector. This device removes tiny particles from the gas stream. After dust removal, gases might pass through a scrubber system. Scrubbers use liquids, often water, to wash out any remaining harmful substances or acidic components. This process cleans the gases further. It ensures that when they are finally released into the atmosphere, they meet strict environmental standards. These standards are set by local and national regulations. This means emissions are clean. There is no visible smoke. There are no harmful pollutants. This commitment to environmental protection makes the Airflow Hoisting Carbonization Furnace a leader in smokeless carbonization technology. It helps businesses operate responsibly.

How are smart systems used to control carbonization temperature, airflow, and time parameters?

Smart systems are very important for the airflow hoisting carbonization process. They control temperature, airflow, and time parameters. This ensures consistent quality and efficient operation. This makes it an automated charcoal making equipment.

Modern airflow hoisting carbonization furnaces often have advanced control systems. These typically include a PLC (Programmable Logic Controller) and an HMI (Human Machine Interface). The PLC is like the brain of the system. It receives information from many sensors. These sensors monitor key process parameters. For example, temperature sensors continuously measure temperature inside the furnace and tanks. Pressure sensors monitor gas pressure. Flow sensors track air and combustible gas flow.

The HMI is a touch screen interface. Operators use it to set desired parameters. They can monitor the process in real-time. Based on sensor data, the PLC automatically adjusts various components. It can control fuel supply to the secondary combustion chamber. This regulates heat. It can also control dampers or fans. This manages airflow. It ensures that the three carbonization stages follow exact temperature curves. The system also precisely controls carbonization furnace temperature control over time. It makes sure each stage lasts for the correct duration. This minimizes human error. It also ensures consistent product quality. It optimizes energy use. This level of control is crucial for high-efficiency biomass charcoal making.

How do we adjust carbonization process parameters for different biomass raw materials?

Adjusting carbonization process parameters is key. It ensures optimal results for different types of biomass raw materials. Each material has unique properties. These properties affect how it carbonizes. This is an important part of raw material pretreatment for charcoal.

Raw materials differ in many ways. They have different moisture levels, particle sizes, and chemical makeups. For example, wood has much lignin. Lignin acts as a natural binder. It forms strong charcoal when heated. Rice husks have less lignin. They have higher silica content. This means they will produce more ash. Because of these differences, you cannot use the same settings for all materials. I always recommend testing different materials. This helps find the best settings.

- Moisture Content: If raw material is slightly wetter, you might need a longer drying stage. Or you might need a higher temperature during drying.

- Particle Size and Density: Denser materials, like briquettes, might need longer carbonization times. This ensures heat penetrates fully. Less dense materials, like wood chips, might need faster heating rates. This avoids excessive burning.

- Chemical Composition: Materials with high lignin content can use lower carbonization temperatures. This saves energy. They still produce good charcoal. Materials with lower lignin might need higher temperatures. Or they might need binders to get strong charcoal. If the goal is high fixed carbon charcoal process, you might need higher temperatures. If the goal is low ash charcoal production method, you need to start with low ash raw materials.

Smart control systems help with these adjustments. They allow operators to save recipes for different raw materials. This makes it easier to switch between materials. It ensures consistent high-quality charcoal production.

How does the airflow hoisting process affect wood charcoal’s fixed carbon and ash content?

The airflow hoisting carbonization process has a direct impact on charcoal quality. This includes its fixed carbon and ash content. These are two very important measures of charcoal quality. This process is key for high fixed carbon charcoal process.

Fixed carbon content measures how much pure carbon is in the charcoal. Higher fixed carbon means better charcoal. It burns hotter and longer. The airflow hoisting process promotes high fixed carbon. This is because it uses indirect heating. Biomass heats in a sealed, oxygen-free environment. This prevents carbon from burning away. Instead, it converts efficiently into fixed carbon. Also, precise carbonization furnace temperature control is important. Higher carbonization temperatures, especially in the deep carbonization stage (e.g., 500-600°C), break down organic matter more completely. This leaves more fixed carbon. This is why this process is great for high-quality charcoal production.

Ash content is the amount of inorganic material left after burning. Lower ash content is usually better. It means less waste and a cleaner burn. The airflow hoisting process itself does not reduce the natural ash in raw material. If your biomass has high ash, your charcoal will also have high ash. This is often called the “ash content curse.” However, this process does not add to the ash content. This is unlike direct burning methods. Direct burning can sometimes mix ash from the fuel source with the charcoal. To achieve low ash charcoal production method, you must start with low ash raw materials. For example, pure wood usually has lower ash than rice husks. So, while the process is excellent for fixed carbon, raw material selection is key for ash content. The process helps maintain the inherent ash level without adding more.

How does the airflow hoisting carbonization process ensure production safety?

Ensuring production safety is extremely important for the airflow hoisting carbonization process. Carbonization involves high temperatures and flammable gases. So, strict safety measures are always in place. This makes it an important part of carbonization furnace safe operation.

First, gas monitoring and ventilation are crucial. Carbonization produces gases like combustible gases and carbon monoxide (CO). CO is a dangerous, odorless gas. The facility must have good ventilation systems. It must also have CO detectors with alarms. These warn workers if CO levels are too high. Workers must wear personal protective equipment (PPE). This includes gas masks when needed. Second, the furnace design itself includes safety features. Inner carbonization tanks are sealed during operation. This prevents oxygen from entering. It also stops gases from leaking out. The main furnace body uses high-quality refractory materials. These handle high temperatures and prevent heat escape. This protects workers.

Third, controlled cooling and discharge are vital. After carbonization, charcoal is very hot. It will catch fire if it touches air. So, inner tanks cool carefully while sealed. They stay sealed until charcoal is at a safe temperature. This prevents accidental fires. Discharge areas must be well-ventilated. This removes any residual gases or dust. Fourth, emergency stop systems are standard. These systems can immediately shut down the process if a problem happens. This includes power failures or gas leaks. Finally, operator training is non-negotiable. All personnel must receive comprehensive training. This covers safe operation, emergency procedures, and equipment maintenance. This training prevents human error. It ensures everyone knows how to react safely. These steps make the airflow hoisting carbonization process safe to operate.

What are the benefits of airflow hoisting charcoal making technology for production operations?

The airflow hoisting charcoal making technology offers many benefits for production operations. These benefits lead to a more efficient, profitable, and environmentally friendly business. This makes it an excellent choice for charcoal production cost optimization.

First, it brings high efficiency and continuous operation. The “one machine, multiple tanks” design means you can load, carbonize, and cool tanks at the same time. This turns a batch process into a quasi-continuous one. This greatly increases daily output. It reduces the time between batches. This means you can produce more charcoal in less time. Second, it offers significant energy savings. The system recycles combustible gases produced during carbonization. It uses them as fuel to heat the furnace. This makes the process largely self-sufficient in energy. This greatly reduces your reliance on external fuel sources. This cuts down on operating costs. It is a true charcoal making energy-saving technology.

Third, it ensures consistent, high-quality product. Precise control of temperature, airflow, and time in an oxygen-free environment leads to uniform carbonization. This results in charcoal with high fixed carbon content and consistent quality. This meets market demands for premium products. Fourth, it is environmentally friendly. Self-ignition of tail gases and subsequent purification steps eliminate smoke and harmful emissions. This helps meet strict environmental regulations. It improves your company’s image. Finally, the design leads to lower maintenance and longer equipment life. Separated inner tanks reduce thermal stress on the main furnace. This extends its lifespan. Maintenance on individual tanks is easier. This reduces downtime. These benefits make the airflow hoisting carbonization process a smart investment for any charcoal production line process.

FAQs

Question 1: What is the main advantage of the airflow hoisting furnace’s indirect heating system?

The main advantage is that it heats biomass in an oxygen-free environment, preventing direct burning. This leads to higher fixed carbon content and better charcoal quality.

Question 2: Can I use raw biomass directly from the field in this carbonization furnace?

No, raw biomass usually requires pretreatment. This includes drying to ideal moisture content (e.g., 10-15%) and reducing particle size for efficient carbonization.

Question 3: How does the furnace handle the environmental impact of carbonization gases?

It uses exhaust gas recycling carbonization. Combustible gases are burned for heat, and remaining tail gases are purified through dust collectors and scrubbers to meet emission standards.

Question 4: What are the key parameters to control for optimal charcoal production?

The key parameters are carbonization temperature, airflow during the heating process, and the duration of each stage (drying, preheating, deep carbonization). Smart control systems help manage these.

Question 5: What is the benefit of the “one machine, multiple tanks” design?

This design allows for quasi-continuous operation. You can load, carbonize, and cool tanks simultaneously, maximizing daily output and improving overall efficiency.

Conclusion

The airflow hoisting carbonization furnace charcoal making process is a complete solution. It efficiently turns biomass into high-quality charcoal. It does this while also being good for the environment. I have seen how this technology improves every part of charcoal production. It starts with careful raw material handling. It continues with precise control of the carbonization process. It includes smart recycling of gases for energy. It also ensures safe and clean emissions. This system gives you a continuous carbonization process. It leads to high fixed carbon charcoal process and charcoal production cost optimization. By using this technology, you get consistent product quality. You also meet today’s strict environmental rules. This makes it a very good choice for modern charcoal production.

About Durable

Durable Machine, established in 2001, is a leading Chinese manufacturer. We specialize in mineral processing equipment and construction machinery. We also apply our industrial process knowledge to biomass energy equipment. Durable designs and builds complete, integrated biomass fuel production lines. We focus on briquette machines and carbonization solutions. Our solutions prioritize efficiency, reliability, and environmental responsibility. Durable’s team works closely with clients. We design systems to match specific biomass types, production needs, and business goals. From initial consultations and plant design to custom equipment manufacturing, installation support, operator training, and comprehensive after-sales service, Durable ensures your investment leads to successful outcomes.

For expert advice and a custom plan for your charcoal production line or vertical hoist biomass carbonization furnace project, contact Durable’s engineering team today.

Durable Machinery

Durable Machinery