Project Update: 1500TPD Coal Slime Dryer Begins Operation

For any large-scale coal washing plant, the management of coal slime is a critical operational and financial challenge. We recently completed the commissioning of a large-scale 1500TPD coal slime dryer project, a landmark achievement that showcases how modern coal slime treatment technology can transform an environmental liability into a significant revenue stream. This project case study details the challenges, our engineered solutions, and the tangible economic outcomes, providing a clear blueprint for potential investors.

The successful and smooth startup of this industrial dryer system was not an accident. It was the result of meticulous planning, robust engineering, and a collaborative partnership with our client. This project proves that with the right equipment and expertise, large volumes of waste coal slime can be efficiently converted into a valuable, marketable fuel product.

Table of Contents

- What Was the Client’s Initial Core Challenge?

- Why Was a 1500TPD Coal Slime Dryer the Chosen Solution?

- What Are the Real-World Results and Economic Benefits?

- How Did We Ensure Smooth Installation and Environmental Compliance?

- Where is the Final Dried Coal Slime Product Used?

- Common Questions About Coal Slime Drying Projects

- Summary and Key Takeaways

- About Durable

- Get Your Custom Project Proposal

What Was the Client’s Initial Core Challenge?

Our client, a major coal producer, operates a high-capacity coal washing plant. While the plant was efficient at producing high-grade coal, it also generated a significant byproduct: approximately 1,500 tons of coal slime every single day.

This material, with an initial moisture content often exceeding 28%, presented several critical problems:

- Economic Loss: The slime contained valuable fine coal particles, but its high water content made it unusable as fuel. It represented a significant loss of potential energy and revenue.

- High Disposal Costs: Storing the wet, sticky slime in large tailings ponds was expensive. It required significant land use and continuous maintenance to prevent environmental issues.

- Logistical Difficulties: Transporting the heavy, wet material was difficult and costly. Its sticky nature also posed challenges for handling equipment.

- Environmental Pressure: There was increasing regulatory pressure to find a more sustainable solution for this industrial waste product, moving away from simple storage.

The client needed a reliable, large-scale solution to dewater this material and unlock its economic value.

Why Was a 1500TPD Coal Slime Dryer the Chosen Solution?

After a thorough consultation and analysis of the client’s operations, we determined that a custom-engineered 1500TPD coal slime dryer was the optimal solution.

The capacity was not arbitrary. It was specifically calculated to match the daily output of their coal washing plant. This ensures that no backlog of wet slime is created, allowing the entire operation to run in a continuous, streamlined flow. A smaller dryer would create a bottleneck, while a larger one would be an inefficient use of capital.

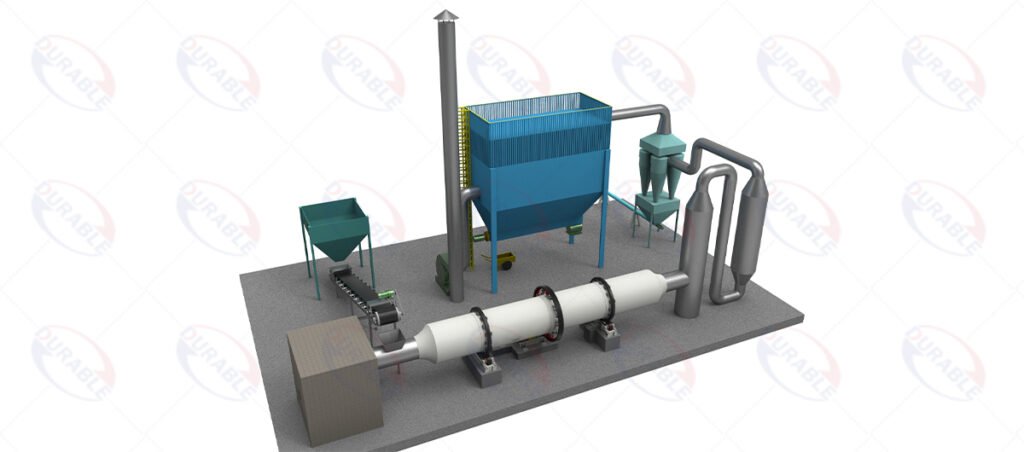

We proposed our heavy-duty rotary drum dryer system for this coal slime drying project for several key reasons:

- High Throughput: The rotary dryer design is proven for handling large volumes of bulk materials continuously.

- Custom Internals: We designed the internal lifters (flights) of the drum specifically for the sticky nature of coal slime. This unique design ensures the material is lifted and cascaded effectively through the hot air stream, preventing clumping and maximizing drying efficiency.

- Thermal Efficiency: The system was engineered with a highly efficient hot air furnace and excellent insulation to minimize fuel consumption per ton of water evaporated, directly impacting the project’s operational costs.

What Are the Real-World Results and Economic Benefits?

The success of any industrial project is measured by its performance and profitability. Since its smooth startup, the 1500TPD coal slime dryer has delivered exceptional results.

Technical Performance:

- Moisture Reduction: The system consistently reduces the moisture content of the coal slime from an initial 28-30% down to a final, stable level of below 12%.

- Increased Calorific Value: By removing the excess water, the calorific value (heating value) of the material increased significantly, transforming it from a waste product into a high-quality industrial fuel.

Return on Investment (ROI):

The economic impact for our client was immediate and substantial.

- New Revenue Stream: The dried coal slime is now a sellable commodity. At a capacity of 1500 tons per day, even a conservative market price for this alternative fuel generates significant daily revenue.

- Eliminated Disposal Costs: The client no longer has to pay for the storage and management of wet slime, turning a daily operational cost into a daily profit.

- Fast Payback Period: Based on the new revenue generated and the operational savings, the initial capital investment in the drying system is projected to have a very attractive payback period, making it a financially sound decision.

How Did We Ensure Smooth Installation and Environmental Compliance?

Executing a project of this scale requires more than just high-quality equipment; it demands expert project management and a commitment to safety and environmental responsibility.

Installation and Commissioning:

Our role extended far beyond manufacturing.

- On-Site Supervision: Durable’s experienced engineers were on-site to supervise the entire installation process, ensuring that the foundation, alignment of the large rotary drum, and assembly of all components met our strict engineering standards.

- Systematic Commissioning: We followed a multi-stage commissioning process: mechanical “cold” runs to verify all moving parts, “hot” runs to test the thermal systems, and finally, a gradual ramp-up to full capacity with the actual coal slime. This methodical approach identified and solved minor issues before they could become major problems, ensuring the “smooth start” the client experienced.

Environmental Compliance:

Meeting local environmental standards was a top priority.

- Advanced Dust Collection: We equipped the coal slime dryer system with a multi-stage dust collection circuit. A high-efficiency cyclone collector captures the majority of larger particles, followed by a large baghouse filter that removes over 99.9% of the remaining fine dust.

- Clean Emissions: This robust system ensures that the air exhausted from the stack is clean and well below the permissible limits for particulate matter, allowing the client to operate in full compliance with environmental regulations.

Where is the Final Dried Coal Slime Product Used?

The successful coal slime utilization is the final step in this value-creation process. The dried, powdered coal slime is now a sought-after alternative fuel for various industrial applications.

The primary end-users for this product include:

- Cement Plants: Used as a supplementary fuel in cement kilns.

- Power Generation Facilities: Blended with higher-grade coal to reduce fuel costs in industrial power plants.

- Industrial Boilers: Used by factories for steam and heat generation.

By providing a consistent, low-moisture fuel source, our client has opened up new markets and created stable, long-term demand for what was once a waste product. For more information on our complete range of industrial dryer systems, please review our product specifications.

Common Questions About Coal Slime Drying Projects

Question 1: What is the typical energy consumption for a coal slime dryer?

A: Energy consumption is a key operational cost. It depends on the initial moisture content, target moisture, and the type of fuel used for the hot air furnace. Our systems, including the use of an efficient biomass burner, are designed for high thermal efficiency to minimize fuel usage per ton of water evaporated. We provide detailed consumption estimates during the project proposal phase.

Question 2: How does the dryer prevent sticky coal slime from clumping inside the drum?

A: This is a critical engineering challenge. We overcome this with a specially designed pattern of internal lifters and, in some cases, a chain-breaking device. This mechanical action continuously breaks up any potential clumps, ensuring the material remains free-flowing for uniform drying.

Question 3: What is the estimated Return on Investment (ROI) period for a project like this?

A: The ROI period varies based on the local market price for the dried slime, the cost of fuel for the dryer, and the client’s previous disposal costs. However, for large-scale projects like this 1500TPD system, the payback period is typically between 12 and 24 months due to the high volume of value being created daily.

Summary and Key Takeaways

This 1500TPD coal slime dryer project is a powerful demonstration of how targeted investment in the right technology can solve complex industrial and environmental problems.

- Problem: 1500 tons of wet coal slime per day created economic loss and environmental liability.

- Solution: A custom-engineered rotary drum dryer system from Durable, designed for high capacity and efficiency.

- Result: A new, profitable revenue stream, elimination of disposal costs, and full environmental compliance.

This case study proves that coal slime treatment is no longer just a cost center; it is a significant profit opportunity for coal washing plants willing to invest in modern drying technology.

About Durable

Since 2001, Durable has been a leading Chinese manufacturer of mineral processing and drying equipment. We specialize in providing robust, reliable, and efficient solutions for clients worldwide. Our factory-direct model and full-service approach—from initial design and manufacturing to on-site installation and support—ensure our partners receive the best possible equipment and expertise for their projects. We have successfully delivered equipment to over 120 countries.

Get Your Custom Project Proposal

If your facility is facing challenges with coal slime or any other high-moisture industrial byproduct, our team of experts can help. Contact us today to discuss your specific material and capacity requirements. We will provide a comprehensive, customized proposal, including technical specifications, pricing, and an ROI analysis for your own drying project.

Durable Machinery

Durable Machinery