Raymond Mill

A Raymond Mill is a highly efficient industrial grinding machine. It is not a crusher like the hammer mill, but a grinder designed specifically to produce fine and ultra-fine powders.

Key Features & Applications

Output Fineness: Highly adjustable, typically from 80 to 325 mesh (approximately 45 to 180 microns). Can be set to produce very uniform powder.

Materials Processed: Ideal for non-flammable, non-explosive, brittle materials with a Mohs hardness below 7. Common materials include:Limestone , Calcite, Barite, Gypsum,Talc, Kaolin Clay.

As a manufacturer with over two decades of experience at Durable, we’ve seen grinding technologies evolve. The Raymond Mill, or Raymond grinding mill, is a classic machine, a true workhorse in the powder processing industry. You might wonder if this established technology can still compete with newer machines. The answer is a definite yes, but its value depends entirely on your specific needs. This guide is for you, the plant owner or manager, who needs straight answers. We will explore how to get the most out of a Raymond Mill, from adjusting the fineness to understanding its real-world operational costs.

Table of Contents

- What Minerals Can a Raymond Mill Process, and What’s the Hardness Limit?

- How Do You Precisely Adjust for 80 to 400 Mesh Fineness?

- What Are a Raymond Mill’s Wear Parts, and What Is Their Lifespan?

- Raymond Mill vs. Vertical Roller Mill (VRM): What Are the Real Differences?

- Why Is My Raymond Mill Not Reaching Its Theoretical Output?

- What Does a Complete Raymond Mill System Include?

- FAQs

What Minerals Can a Raymond Mill Process, and What’s the Hardness Limit?

A Raymond Mill is primarily designed for grinding non-flammable, non-explosive, and brittle materials. The key operational limit is the material’s Mohs hardness, which should be below 7. It excels at processing a wide range of common industrial minerals. Some of the most typical materials you can process efficiently include limestone, calcite, barite, dolomite, potassium feldspar, marble, talc, gypsum, kaolin, bentonite, and phosphate rock. The reason for this hardness limit is not because the mill lacks the force to break harder materials, but because of abrasive wear. The grinding action in a Raymond Mill relies on pressure and friction as rollers grind material against a stationary ring. When you process highly abrasive materials with a hardness above 7, like quartz or granite, the wear rate on the grinding rollers and ring increases dramatically. This makes the operational cost, specifically your cost per ton for wear parts, uneconomically high and leads to frequent downtime for maintenance. For these harder materials, you would be better served by a different type of mill, like a Ball Mill, which uses a different grinding principle.

How Do You Precisely Adjust for 80 to 400 Mesh Fineness?

Achieving your target particle size, from a coarse 80 mesh to a fine 400 mesh, depends on the precise tuning of the classifier, also known as the analyzer. The classifier sits on top of the main mill and acts as a quality control gatekeeper. It uses a combination of airflow from the blower and centrifugal force from its own rotation to separate particles. Finer, lighter particles are carried by the air through the classifier to the collection system, while coarser, heavier particles are thrown to the side and fall back into the grinding chamber for further processing. You can think of it as a bouncer at a club, only letting the “right-sized” particles through.

You have two primary controls to achieve your ideal fineness:

- Classifier Speed: This is your main adjustment. The classifier is driven by its own motor. Increasing the rotational speed of the classifier’s vanes generates more centrifugal force. This force makes it harder for particles to pass through, so only the very finest powder can escape. This gives you a higher mesh number (finer product). Conversely, decreasing the speed reduces the separating force, allowing coarser particles to pass through easily, resulting in a lower mesh number.

- Blower Air Volume: The main blower creates the airflow that lifts the ground powder from the mill chamber up to the classifier. Adjusting the damper on the blower changes this airflow. Increasing the air volume creates a stronger upward draft that can carry heavier (coarser) particles. Decreasing the air volume creates a gentler draft that can only lift the lightest (finest) particles. You must balance the blower’s air volume with the classifier’s speed to maintain stable production and achieve the desired fineness.

| Setting Combination | Expected Fineness | Key Consideration |

|---|---|---|

| High Classifier Speed + Moderate Airflow | Fine Powder (300-400 Mesh) | This creates high internal circulation, which can reduce overall output. |

| Low Classifier Speed + Moderate Airflow | Coarse Powder (80-150 Mesh) | This setting maximizes output because material passes through easily. |

| High Classifier Speed + High Airflow | Unstable; high airflow may force coarse particles through. | This can lead to an inconsistent product with a wide particle size distribution. |

| Low Classifier Speed + Low Airflow | Inefficient; low airflow may not be able to lift enough material. | This will significantly lower your production capacity. |

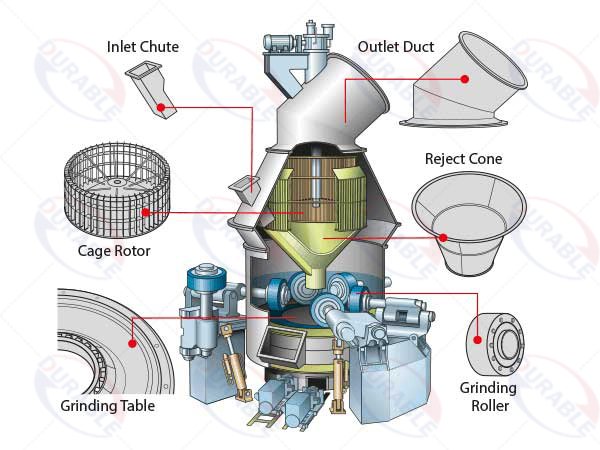

What Are a Raymond Mill’s Wear Parts, and What Is Their Lifespan?

Understanding the wear parts is crucial for you to accurately budget for maintenance and calculate your true production cost. In a Raymond Mill, the heavy lifting of grinding is done by just a few key components that are designed to be replaced. These are your primary consumables. The three main wear parts are the Grinding Roller, the Grinding Ring, and the Shovel Blade (also called a scraper). The Shovel Blade’s job is to scoop material from the bottom of the mill and toss it up into the gap between the rollers and the ring. The rollers then spin and press against the ring, crushing and grinding the material trapped between them.

The lifespan of these parts depends almost entirely on the hardness and abrasiveness of the material you are grinding. For a soft material like calcite (Mohs hardness 3), a set of high-manganese steel rollers and a ring might last for 400-500 hours. However, if you are grinding a harder material like barite (Mohs hardness 3.5 but more abrasive), that lifespan could be cut in half. That’s why we, as a manufacturer, always recommend using parts made from high-chromium alloy steel for tougher applications. While they have a higher initial price, their superior wear resistance can double or triple the service life, leading to a lower overall cost per ton and less downtime for your operation. You should always think in terms of Cost per Ton, not just the price tag of the spare part.

Raymond Mill vs. Vertical Roller Mill (VRM): What Are the Real Differences?

This is a critical decision when you are planning a new plant or an upgrade. The Raymond Mill is a classic, trusted technology, while the Vertical Roller Mill (VRM) is a more modern, integrated solution. They both make powder, but they are suited for very different scales of operation and budgets. The biggest advantage of the Raymond Mill is its lower initial investment and simplicity. The machine has a straightforward mechanical design, which means your local maintenance team can likely handle most repairs without needing highly specialized training. It’s a robust and forgiving machine.

However, the VRM is superior in terms of efficiency and scale. A VRM integrates crushing, grinding, drying, and classifying into a single unit. It consumes about 20-30% less electricity per ton compared to a Raymond Mill system producing the same product. Furthermore, a single large VRM can have a massive output, reaching hundreds of tons per hour, whereas a large Raymond Mill tops out at around 40-50 tons per hour. If you have a large-scale operation and high electricity costs, the long-term energy savings of a VRM can justify its much higher initial purchase price. For small to medium-sized plants, or for operations where capital is limited, the Raymond Mill often provides a much better and faster return on investment.

Why Is My Raymond Mill Not Reaching Its Theoretical Output?

This is one of the most common questions we hear from plant operators. You’ve bought a mill rated for 10 tons per hour, but you are only getting 7. The gap between theoretical capacity and actual output is almost always caused by one of a few key factors, and material moisture is the number one suspect. A Raymond Mill operates as a dry grinding system that uses air to transport the powder. If your raw material has a moisture content above 6%, the fine powder will become sticky. This sticky material will coat the rollers and ring, reducing grinding efficiency. Even worse, it will clog the small holes in the classifier and blind the filter bags in your dust collector, choking the entire system’s airflow. When the air can’t flow, the mill can’t produce.

Beyond moisture, you should also check these things:

Worn Parts: Are your rollers, ring, and shovel blades worn out? Even partial wear reduces grinding efficiency and lowers output.

- Inconsistent Feeding: The vibrating feeder must provide a steady, consistent flow of material to the mill. If you “slug feed” the machine (dumping in large amounts at once), you will overload it and hurt production.

- Incorrect System Settings: If your classifier speed is set too high for your target fineness, you are creating excessive internal circulation. This means the same material is being ground over and over, which consumes power and occupies mill capacity without creating new product.

- Air Leaks: The system relies on a closed-loop, negative-pressure airflow. Any leaks in the pipes or at inspection doors will reduce the blower’s ability to lift material, directly impacting your output.

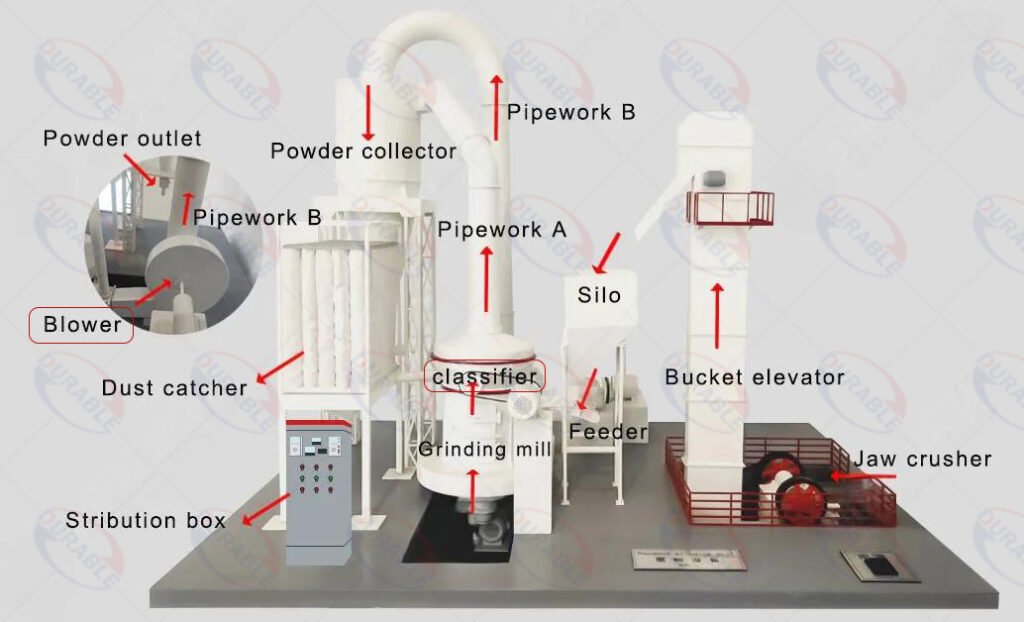

What Does a Complete Raymond Mill System Include?

When you invest in a Raymond Mill, you are actually investing in a complete grinding system. The mill itself is the heart, but it cannot function without its supporting cast of equipment. A standard, fully functional grinding production line is designed for continuous, automated operation and effective dust control.

Here are the essential components of a complete system we design for our clients:

- Primary Crusher: Usually a Jaw Crusher to break large rocks down to a size (< 30mm) that the Raymond Mill can accept.

- Hopper & Vibrating Feeder: The crushed material is stored in a hopper and then fed into the mill at a constant, adjustable rate by a vibrating feeder.

- Raymond Mill Main Unit: This is where the grinding happens, with its rollers, ring, and shovel blades.

- Classifier (Analyzer): Positioned above the mill, it separates the powder by size.

- Cyclone Collector: Air from the mill, carrying the finished powder, enters this cyclone. The cyclone uses centrifugal force to separate about 85-90% of the powder from the air, which then falls out the bottom.

- Blower: This large fan is the lungs of the system. It creates the airflow that moves the powder from the mill to the cyclone and dust collector.

- Pulse Jet Baghouse Dust Collector: The air leaving the cyclone still contains the finest dust particles. This air is passed through a baghouse filter, which captures the remaining dust before the clean air is released. This is absolutely essential for meeting modern environmental emission standards.

- Pipes, Support Structures, and an Electrical Control Panel: These connect everything and allow you to operate the entire system from one central point.

FAQs

Q1: Is a Raymond Mill still a good investment (ROI) for a new plant?

A: Yes, for small to medium-sized plants, it’s often the smartest choice. Its low initial capital cost and simple maintenance lead to a faster return on investment compared to more complex systems like a Vertical Roller Mill, especially if your target capacity is under 30 tons per hour.

Q2: How do you configure a dust collector to meet environmental standards?

A: You must use a two-stage collection system. A cyclone collector captures the bulk of the product first. Then, all air must pass through a high-efficiency pulse-jet baghouse filter before being discharged. The size of the baghouse is calculated based on the total system air volume to ensure low emission levels.

Q3: Can I change the fineness while the mill is running?

A: Yes. The fineness is controlled by the classifier’s speed, which is typically managed by a variable frequency drive (VFD) on its motor. You can adjust the speed from the main control panel while the system is operating to fine-tune your output powder.

Q4:What is the main cause of heavy vibration in a Raymond Mill?

A: Besides an un-level foundation, the most common cause is uneven wear on the grinding rollers or a broken shovel blade. This creates an unbalanced rotating mass, leading to severe vibration that can damage the main bearings and gearbox if not addressed quickly.

Q5: Why is the blower so important?

A: The blower does more than just move powder. It controls the system’s capacity. The volume of air directly determines how much material can be lifted from the grinding chamber to the classifier per minute. An undersized blower will starve the mill, even if the mill itself has more grinding potential.

Durable Machinery

Durable Machinery