Sawdust Drying: Key Strategies for Precise Moisture Control, Boosting Efficiency and Quality?

Moisture control in sawdust drying is absolutely crucial. My experience confirms this. This process is complex, but vital for success. Incorrect moisture levels impact everything. They affect your product quality. They waste your energy. They can even create fire hazards. Sawdust, by its nature, has inconsistent initial moisture. It can range from very wet to quite dry. Your final product requires a precise moisture target. This article will show you how to manage this accurately. We will guide you to achieve optimal control. This helps you get the best possible results.

Table of Contents

- Why Is Precise Moisture Control Essential for Sawdust Drying Success?

- How Do We Measure and Pre-treat Initial Sawdust Moisture?

- How Do Dryers Efficiently Remove Sawdust Moisture Internally?

- How Do Sensors and Automation Precisely Control the Drying Process?

- How Do We Quickly Detect and Ensure Final Sawdust Moisture Compliance?

- What Design Features Should You Look for in a Sawdust Dryer?

- How Do We Balance Drying Efficiency and Energy Consumption for Optimal Moisture Control?

- What Are Common Moisture Fluctuation Problems and Their Precise Solutions?

- How Are Smart Drying and Big Data Revolutionizing Sawdust Moisture Control?

- Frequently Asked Questions

- About Durable

Why Is Precise Moisture Control Essential for Sawdust Drying Success?

Precise sawdust drying machine moisture control is critical. It directly impacts your product quality. It also affects operational safety. Sawdust varies greatly in moisture content. Its final use depends on exact moisture levels. Getting this wrong impacts everything. It affects pellet density and briquette strength. It increases energy consumption. It causes machine wear. Most dangerously, it raises the risk of fire or explosion. Sawdust, by its very nature, is highly inconsistent in its initial moisture. This control ensures both safety and quality. This ensures your operation runs smoothly and profitably.

How Moisture Affects Product Quality and Value?

I have seen sawdust moisture range from 10% to 60%. Each final product needs a very narrow range. For biomass pellets, the target is often 8-12% moisture. Too much water makes soft pellets. They break easily during handling. They also have lower energy density. Too little water makes brittle pellets. These also do not hold together well. They crumble. Incorrect moisture also means poor combustion for biomass fuel production. This reduces its heating value. This affects the final customer’s use. Consistency in biomass pellet moisture is key for market acceptance. It also guarantees consistent performance. This precise moisture level directly influences the quality and market value of your final product.

Why Moisture Control Is Crucial for Operational Safety?

Over-drying sawdust is dangerous. It becomes very dry and powdery. This creates fine dust in the air. This dust can easily explode under certain conditions. We must manage air flow and temperature carefully. Wet sawdust also causes issues. It can clog equipment. It can cause mold growth in storage. Mold leads to product spoilage. It also causes machine downtime. Uncontrolled moisture affects machine wear too. It makes machines less efficient. It can even cause explosions. So, precise moisture control keeps things safe. It avoids costly problems. It prevents accidents. This approach protects both your equipment and your personnel. It helps you maintain a safe working environment at all times.

How Do We Measure and Pre-treat Initial Sawdust Moisture?

Accurate measurement and proper pretreatment of initial sawdust moisture are essential. They minimize variability in the raw material. This prepares the material for efficient drying. You cannot control what you do not measure. Incoming sawdust can be very wet from fresh wood. Or it can be somewhat dry from other sources. I always emphasize testing samples. This tells us what we are starting with. Pre-drying steps also help. They reduce the burden on the main dryer. This saves a lot of energy. These steps make the whole process smoother. It means better sawdust drying efficiency. This foundation is crucial for successful operation. It addresses the core challenge of sawdust’s inherent variability.

Technologies for Measuring Incoming Sawdust Moisture?

We use several ways to measure incoming moisture. Sampling is key for accuracy. You need random, frequent, and representative samples. This prevents false readings. The oven-drying method is the most accurate. We take a sample. We weigh it. We dry it in an oven at 105°C. We weigh it again when it is dry. This method takes hours. So, it is for calibration and lab analysis. For real-time data, we use moisture sensors. These are often NIR (Near-Infrared) sensors. They sit over the conveyor belt. They give continuous readings. They are fast. They do not touch the material. But they need regular calibration against the oven method. Capacitance sensors are good for quick spot checks. They are less accurate. They are affected by material density. On-line microwave sensors penetrate deeper. These different tools combine for comprehensive dryer moisture detection.

| Measurement Method | Pros | Cons | Your Implication |

|---|---|---|---|

| Oven Drying (Gravimetric) | Most accurate, for calibration | Time-consuming, not real-time | Gold standard for calibrating online sensors |

| Near-Infrared (NIR) Sensors | Real-time, non-contact, continuous | Needs calibration, affected by dust | Key online monitoring tool, improves drying efficiency |

| Capacitance/Resistive | Quick spot checks, low cost | Less accurate, affected by density | Suitable for auxiliary or simple applications |

| Online Microwave Sensors | Highly accurate, less affected by dust/surface texture | More expensive, complex | Can penetrate deeper for consistent readings |

Effective Strategies for Sawdust Pre-treatment?

After measuring, we must manage the moisture. We aim to minimize the variability of the material entering the dryer. Blending different sawdust batches helps. It averages out the moisture content. We store materials in covered areas. This protects them against rain. This prevents moisture spikes. For very wet material (over 50% moisture), mechanical dewatering helps. A screw press can remove a lot of water before thermal drying. This saves significant energy in the main rotary dryer. Pre-shredding to a uniform particle size also makes drying better. It ensures even drying throughout the batch. These steps make the dryer’s job much easier. They reduce energy waste. This is crucial for efficient material pretreatment. A properly sized surge bin also helps. It ensures a consistent, regulated flow of material.

How Do Dryers Efficiently Remove Sawdust Moisture Internally?

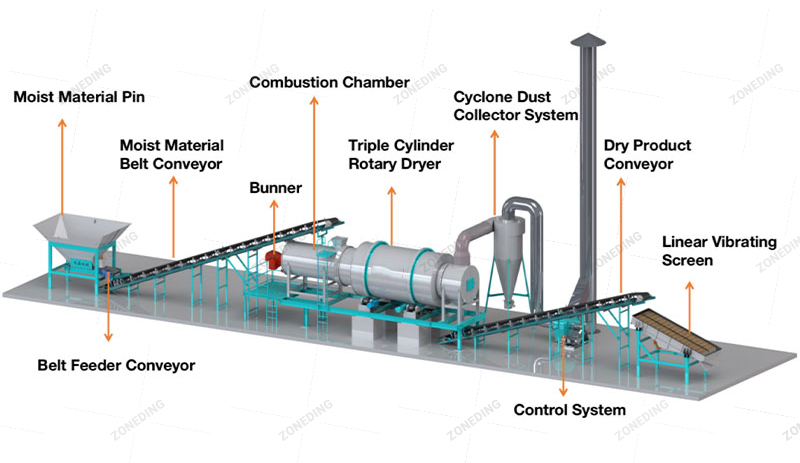

High-efficiency dryers, like rotary drum dryers, use a combination of heat transfer and material movement. This design maximizes contact between hot air and sawdust. It ensures thorough moisture removal. Inside a sawdust dryer, sawdust constantly tumbles. It mixes with hot air. The hot air usually comes from a biomass burner. Flights inside the drum lift the sawdust. They drop it through the hot air stream. This constant movement exposes all particle surfaces to drying. This ensures even drying. It prevents wet spots. This makes the drying process very efficient. This is crucial for achieving target biomass pellet moisture. It also boosts overall productivity. The secret lies in the optimized heat and material exchange.

The Secrets of Heat and Material Exchange?

The hot air usually flows in the same direction as the sawdust. This is called co-current flow. It helps dry very wet material faster. As the sawdust moves through the mineral dryer, it gradually loses moisture. The air also cools down. The design of the flights inside the drum is key. They control how long the material stays in the dryer. They also control how well it mixes. This ensures every particle gets enough drying time. It helps prevent over-drying of some parts. It also prevents under-drying of others. This balance is vital for efficient moisture removal. This optimized heat and material exchange is at the core of effective drying. It makes sure every piece of sawdust reaches the target moisture level consistently.

How Do Sensors and Automation Precisely Control the Drying Process?

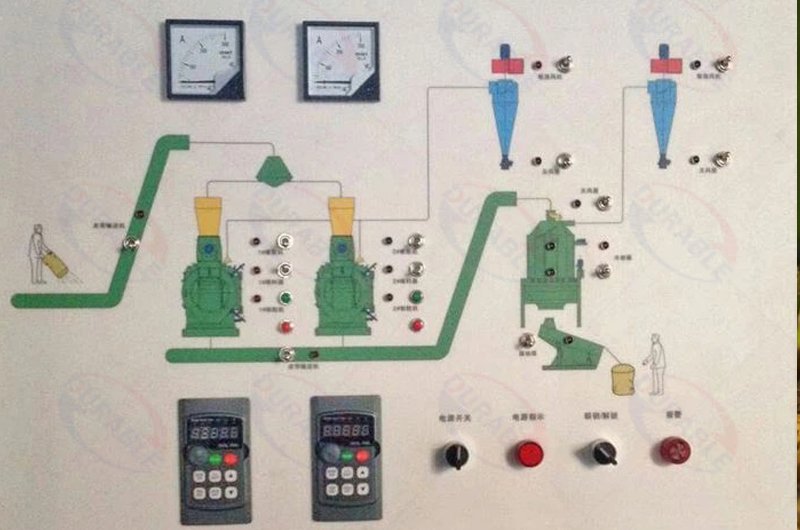

Sensors provide real-time data on moisture and temperature. This data feeds into automated control systems. These systems make dynamic adjustments. They ensure optimal drying conditions. Modern biomass dryers are not manually controlled. We use advanced sensors. These sensors constantly check conditions inside the dryer. For example, NIR sensors measure final moisture. Temperature sensors monitor exhaust gas. This information goes to a PLC (Programmable Logic Controller). The PLC then adjusts parameters. It changes feed rate. It changes burner output. This constant feedback loop means precise sawdust drying machine moisture control. It maximizes sawdust drying efficiency. It also ensures consistent product quality batch after batch. This is where the dryer’s control system and operational parameters truly come into play.

Real-Time Sensor Technologies in Action?

Online moisture sensors are critical. They are placed at the dryer’s output. They tell us the exact moisture of the dried sawdust. Exhaust gas temperature is also important. As material gets drier, exhaust gas tends to get hotter. This tells us if we are over-drying the product. This is an indirect measure but crucial for safety and efficiency. These sensors help prevent wasting heat. They also help stop potential fire risks from overheating. The data from these sensors helps the control system. It makes tiny adjustments to the dryer settings. This keeps the final moisture very stable. This is crucial for hitting specific biomass pellet moisture targets. These technologies are at the heart of dryer automation. Product temperature monitoring also gives an indication. Overly hot product suggests over-drying.

Automated Systems and Key Dryer Adjustments?

Our PLC-based control systems are very smart. They take sensor data. They compare it to the set target moisture. Then, they adjust dryer parameters in real time. This is the “how” of active control. The goal is to dynamically adjust dryer parameters based on the measured incoming and outgoing moisture. If the final moisture is too high, the system might slow the feed rate. This gives material more residence time. Or it might increase burner fuel. This adds more heat. If moisture is too low, it does the opposite. It increases feed rate. It reduces heat. This continuous adjustment loop ensures the dryer always performs at its best. It optimizes drying process optimization. This saves energy. It ensures consistent product quality. The material feed rate is often the first and most effective adjustment. Heat input and burner control are secondary. Airflow and dryer rotational speed are also adjusted.

How Do We Quickly Detect and Ensure Final Sawdust Moisture Compliance?

After drying, quick and accurate final sawdust moisture detection is vital. It verifies product quality. It confirms the drying process was successful. The drying process ends when the material leaves the sawdust dryer. But our job is not finished. We need to confirm the final moisture. This step is about quality assurance. It makes sure the dried sawdust is ready for the next step. For example, ready for making biomass pellets. This final check uses quick methods. It also uses traditional lab tests for verification. This dual approach ensures high confidence in the product. It meets all specified quality standards and ensures customer satisfaction.

Online Versus Offline Detection Methods?

For online detection, we use NIR moisture sensors at the discharge point. They provide continuous feedback on the material exiting the dryer. This is the primary check for continuous operations. For offline or spot checks, we still use the oven drying method. We take samples from the final product stream regularly. We weigh them. We dry them in an oven. This confirms the accuracy of our online sensors. These checks are done routinely. This dual approach ensures high confidence in our final product’s moisture content. It supports the quality of biomass fuel production. It is part of our standard quality control. This combination of methods gives you both real-time insights and verifiable accuracy.

What Design Features Should You Look for in a Sawdust Dryer?

Key design features like drum type, heat source, and control system directly impact moisture accuracy. They also affect sawdust drying efficiency. Not all dryers are the same. A well-designed biomass dryer makes moisture control much easier. For sawdust, rotary dryers are common. Their internal flight design is very important. It ensures good mixing and material flow. The heat source matters too. A stable heat source helps prevent temperature swings. A good control system is vital. It must connect to sensors. It must make precise adjustments. These features combine to ensure reliable sawdust drying machine moisture control. This leads to optimal performance. The dryer itself must be appropriately sized and designed for the material and desired throughput. A poorly designed dryer will inherently struggle with control.

Adapting Different Dryer Types for Sawdust?

For sawdust, a triple pass rotary drum dryer is highly efficient. It has three drums placed inside each other. This design greatly increases the contact area. It extends the drying path for the material. This maximizes heat transfer. It means less energy use for the same output. Flash dryers are good for very fine, wet sawdust. They use high-velocity hot air to quickly dry the material. Choosing the right type depends on your specific sawdust characteristics. It depends on your required output volume. It also depends on your desired final sawdust moisture level. We help you choose the best fit. This choice impacts both drying performance and overall operational cost.

Heat Source Selection and Energy Reduction?

The heat source directly affects your operating costs. Biomass burners are popular choices. They use waste materials like wood chips or other biomass for fuel. This significantly reduces operating costs. They offer stable heat. This helps maintain consistent drying temperatures. We also look at heat recovery systems. These capture waste heat from exhaust gases. They use it to preheat incoming air. This significantly lowers energy consumption reduction. It improves overall drying efficiency. It makes the drying process more sustainable. This is an important consideration for many businesses. This helps you achieve a more environmentally friendly and economically sound operation.

How Do We Balance Drying Efficiency and Energy Consumption for Optimal Moisture Control?

Achieving optimal sawdust drying machine moisture control involves a delicate balance. You must maximize sawdust drying efficiency while minimizing energy consumption. High efficiency often means lower energy use per unit of product. But sometimes, pushing too hard for speed can waste energy. It can also lead to inconsistent moisture in the product. The goal is to find the sweet spot. This means using a good dryer design. It also means having smart control systems. You pre-treat material. You recover heat. All these actions contribute to this balance. This is the core of drying process optimization. It requires careful planning and continuous monitoring to maintain peak performance and cost-effectiveness.

Strategies for Optimizing Feed and Heat Management?

We continuously monitor the initial sawdust moisture content. If it is very wet, we reduce the feed rate. This gives it more time in the dryer. If it is drier, we can increase the feed rate. This maintains output. We also carefully manage burner temperature. It should be hot enough to dry effectively. But not so hot that it wastes energy. Or causes over-drying. Exhaust gas temperature helps us control this. Keeping it stable means stable drying. It avoids energy waste. These precise adjustments keep the system running efficiently. This balances output with resource use. It optimizes both the throughput and the quality of the dried sawdust.

Combining Automation with Energy Reduction?

Automated control systems are key here. They make continuous small adjustments. This keeps the dryer running at peak efficiency. They react to changes in incoming material moisture. They respond to ambient conditions. This proactive approach prevents large swings in temperature or moisture. This prevents energy waste. It helps achieve consistent final sawdust moisture. This is vital for biomass pellet moisture and overall efficiency. This proactive approach saves fuel and electricity. This directly leads to energy consumption reduction. It enhances both environmental and economic performance. A well-programmed PLC/DCS with PID loops is essential. Manual control simply cannot achieve this level of accuracy or energy efficiency.

What Are Common Moisture Fluctuation Problems and Their Precise Solutions?

Moisture fluctuations are common during sawdust drying. We use targeted solutions to maintain stability. These solutions address issues from inconsistent feed to equipment wear. Even with good systems, problems can arise. Raw material moisture can change suddenly due to different sources. Equipment can wear down over time. Sensors might get dirty. These issues cause moisture fluctuations. We identify these problems quickly. Then we apply specific solutions. This ensures our sawdust dryer keeps running smoothly. It maintains consistent output. This proactive problem-solving is part of our commitment to quality. It ensures your operation remains efficient despite challenges.

How to Address Sudden Changes in Feed Moisture?

Sudden changes in initial sawdust moisture are a big challenge. Our online moisture sensors at the feed point help. They detect these changes fast. The automated system then immediately adjusts the feed rate. It might also adjust the heat input. This keeps the drying process stable. Blending incoming material more thoroughly also helps. It smooths out these sudden variations. This ensures a more consistent feed to the biomass dryer. Having sufficient raw material storage buffers also helps to manage variable incoming moisture. A “first-in, first-out” strategy for your raw material storage is essential to minimize variability.

The Importance of Equipment Maintenance and Sensor Calibration?

Over time, dryer components can wear. Flights inside the drum might get damaged. This affects material movement and mixing. This leads to uneven drying. Regular maintenance checks are essential. We replace worn parts promptly. Sensors also need regular calibration. Dust can cover them. This affects their accuracy. We routinely clean and calibrate all moisture sensors. This ensures they give correct readings. Correct readings are vital for precise control. They help prevent moisture fluctuations. This is a critical part of maintaining dryer moisture detection accuracy. Preventive maintenance keeps all mechanical and control components in top condition. Sensors that drift or are covered in dust are worse than no sensors at all.

How Are Smart Drying and Big Data Revolutionizing Sawdust Moisture Control?

Smart drying and big data are transforming sawdust drying machine moisture control. They offer predictive capabilities. They enable continuous optimization. The future of sawdust drying efficiency is smart technology. We are moving beyond simple automation. We use data from many sensors. We use historical performance data. This allows us to predict changes. We can then adjust dryer settings proactively. This minimizes deviations. It leads to even better consistency. It also reduces costs. This is the next step for biomass dryers. These innovations are creating more efficient and reliable systems. This integrated approach elevates control from reactive to proactive, ensuring superior results.

Predictive Maintenance and Performance Optimization?

Smart systems collect huge amounts of data. This includes sensor readings. It includes machine performance. It includes maintenance records. We use this data to predict equipment failures. We can schedule maintenance before a problem occurs. This prevents unexpected downtime. It also optimizes dryer settings. The system learns what works best over time. It continuously improves drying process optimization. This leads to consistent final sawdust moisture. It also leads to maximum energy savings. This predictive capability significantly extends equipment lifespan and improves overall operational uptime. It allows you to maximize your investment and ensure continuous, high-quality production.

Remote Monitoring and Expert Systems?

Modern systems allow remote monitoring. Our experts can check dryer performance from anywhere in the world. They can provide advice. They can even make adjustments remotely. This ensures continuous optimal operation. It also allows for quick troubleshooting without needing on-site personnel. Some systems include expert algorithms. These can suggest solutions to complex problems. They can even learn from new data. This means better control. It means more consistent biomass pellet moisture. This is a big step for the industry. This level of dryer automation enhances operational flexibility and responsiveness. Skilled operators are still vital. They monitor, troubleshoot, and make informed decisions when unusual conditions arise, working alongside the smart systems.

Frequently Asked Questions

Question 1: What happens if sawdust moisture content is too high during drying?

Too much moisture lowers drying efficiency. This increases energy consumption. It also hurts product quality. For example, biomass pellets become loose. They break easily. This lowers their market value. High moisture can also cause equipment to clog.

Question 2: How do I know if my sawdust dryer needs an upgrade?

If your dryer uses too much energy, or cannot reach stable final sawdust moisture, it may need an upgrade. Frequent breakdowns are a sign. Inconsistent product quality also points to this need. Consider using a more efficient biomass dryer and automated control systems.

Question 3: Can smart drying systems really save money?

Yes, smart drying systems can save significant costs. They precisely control moisture. They optimize energy use. They also reduce manual intervention. This lowers fuel and electricity bills. They also reduce product waste. This boosts sawdust drying efficiency.

Question 4: What is the target moisture range for dried sawdust?

The target moisture range for dried sawdust depends on its final use. For example, for making biomass pellets, ideal moisture is usually between 8% and 12%. Other uses may have different needs. Accurate moisture measurement is key to meeting the target.

About Durable

At Durable, we engineer and manufacture mineral processing and drying equipment. We have been doing this since 2001. We do not just sell machines. We build complete solutions. Our team of 15 engineers designs custom systems. We ensure excellence in quality control at every stage. We serve B2B clients globally. We deliver advanced equipment from Zhengzhou. We export to over 120 countries.

Durable Machinery

Durable Machinery