Scaling Up: Guide to Profitable Charcoal Kilns

Moving beyond small-scale methods to begin commercial charcoal production is a significant business decision. This process transforms low-cost biomass into a high-value product. However, a common critical mistake is viewing an industrial charcoal kiln as a simple oven. With deep experience in high-temperature processing equipment, it’s clear that a modern furnace is a precision chemical reactor. Success in mass producing charcoal lies in mastering the science of pyrolysis, not just the art of “burning wood.” This guide explains how to achieve this.

Table of Contents

- Which Industrial Carbonization Furnace Is Best for Scale Production (Continuous vs. Batch)?

- How to Maximize the Charcoal Yield Rate and Ensure Stable Quality?

- How to Maximize the Charcoal Yield Rate and Ensure Stable Quality?

- What Is the Investment Budget for a Complete Industrial Charcoal Production Line?

- How Do You Handle the Smoke Produced During the Process to Meet Environmental Standards?

- How to Adjust the Carbonization Process for Different Raw Materials?

- What Are Some Methods to Reduce Operational Costs and Labor Dependency in Mass Production?

- FAQ

- Conclusion: Your Success is Built on an Efficient System

- About Durable

Which Industrial Carbonization Furnace Is Best for Scale Production (Continuous vs. Batch)?

When planning to mass produce charcoal, the biggest enemy is not the carbonization time itself, but the “downtime.” This is the time spent loading, cooling, and unloading. A traditional kiln might hold a large volume, but if it takes two days to cool down, production comes to a standstill.

The best furnace for scale production minimizes downtime, not just maximizes batch size. It is essential to consider the total cycle time. For industrial scale, there are two main choices:

- Modern Batch Systems (e.g., Hoisting Furnaces): These are the best entry point for industrial production. A system like the Vertical Hoist Biomass Carbonization Furnace uses multiple inner pots. While one pot is processing inside the furnace, another is cooling safely outside, and a third is being loaded. The furnace itself never stops working. This drastically reduces “ineffective time” and multiplies daily output.

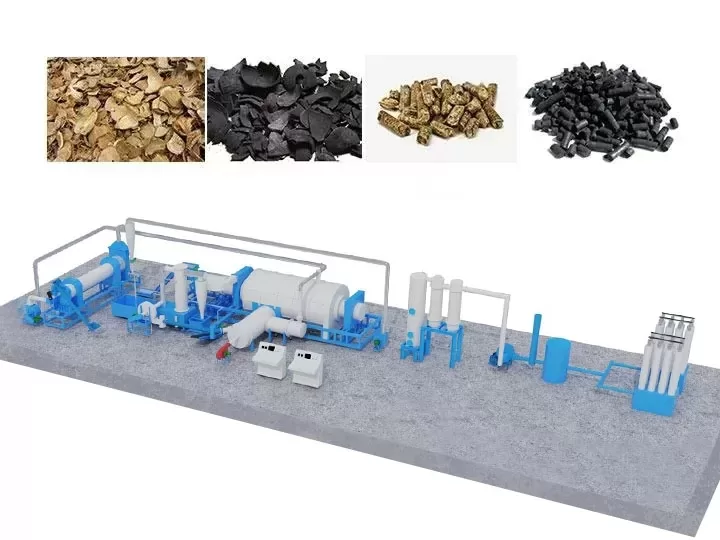

- Continuous Carbonization Furnaces: This is the ultimate solution for large-scale, automated production. Raw material is continuously fed into one end of a rotating drum or furnace, and finished charcoal is continuously discharged from the other. A rotary drum biomass carbonization furnace requires minimal labor and offers the highest daily throughput, making it ideal for a major charcoal production line.

The choice depends on the investment level and target output. For any serious commercial operation, the goal is to keep the heat source working 24/7.

How to Maximize the Charcoal Yield Rate and Ensure Stable Quality?

Industrial biomass carbonization is a systematic process. Each step is designed to prepare the material perfectly for the next, ensuring a stable and high-quality final product.

The process flow of a modern charcoal making machine system is as follows:

- Raw Material Preparation: Your raw material (wood logs, briquettes, coconut shells) must have a moisture content below 15-20%. If it is too wet, you will waste a huge amount of energy just boiling off water. For logs or large pieces, they are typically cut to a uniform size.

- Loading: The prepared material is loaded into the inner pot of a batch furnace or the feed hopper of a continuous furnace.

- Carbonization (Pyrolysis): The material is heated in an oxygen-free environment. As the temperature rises, the biomass breaks down chemically. It releases moisture, then wood vinegar and tar, and finally a combustible gas (syngas).

- Syngas Recycling: This is the key to an efficient furnace. The flammable syngas produced during carbonization is captured, purified, and piped back to the furnace’s burner. It becomes the fuel that sustains the carbonization process. After the initial preheating, a well-designed furnace requires almost no external fuel.

- Cooling: The hot charcoal must be cooled down completely in an oxygen-free environment. This is critical for preventing it from turning to ash and for ensuring its structural strength.

- Discharging & By-product Collection: Once cooled, the finished charcoal is discharged. During the process, the condensed smoke forms wood vinegar and tar, which are collected in separate tanks.

How to Maximize the Charcoal Yield Rate and Ensure Stable Quality?

Many beginners focus only on the charcoal yield rate, thinking that a higher yield is always better. This is a common mistake. The true value of your charcoal is determined by its quality, specifically its fixed carbon content.

Stop focusing on the highest yield; focus on the right fixed carbon content for your target market. The carbonization temperature and duration are the two levers you control to determine this balance. A higher final temperature leads to a lower yield but a much higher quality charcoal.

| Carbonization Temperature | Charcoal Yield Rate | Fixed Carbon Content | Characteristics & Use Cases |

|---|---|---|---|

| Low Temp (< 450°C) | High (e.g., 35-40%) | Low (e.g., 60-75%) | Contains more impurities, produces more smoke when lit. Suitable for basic industrial fuel. |

| Medium Temp (450-600°C) | Medium (e.g., 30-35%) | Good (e.g., 75-85%) | Good balance. Low smoke, high heat. Ideal for BBQ and restaurant use. This is the sweet spot for most commercial charcoal production. |

| High Temp (> 600°C) | Lower (e.g., 25-30%) | Very High (> 85%) | Extremely pure, hard, and long-burning. Premium product for high-end grilling or industrial uses like silicon production. |

To ensure stable quality, you must have a furnace with precise temperature control and a consistent raw material.

What Is the Investment Budget for a Complete Industrial Charcoal Production Line?

The carbonization furnace price is only one part of your total investment. To build a reliable and efficient charcoal production line, you need to budget for the entire system.

A typical investment budget includes:

- Pre-Processing Equipment (15-25%): This could include wood splitters, briquette machines if you are carbonizing briquettes, and dryers if your raw material has high moisture content.

- The Carbonization Furnace (40-50%): This is the core of your investment. The cost will vary significantly between a basic batch kiln and a fully automated horizontal charcoal carbonization furnace.

- Environmental & By-product Systems (15-20%): This includes the equipment for syngas purification and recycling, and the condensation system for collecting wood vinegar and tar. This is not an optional expense in modern operations.

- Post-Processing Equipment (10-15%): This might include a charcoal crusher and screening machine for sizing the charcoal, or a briquetting machine to press charcoal powder into uniform shapes.

- Site Works and Installation (10%): This covers the concrete foundations, shed or building, and the cost of professional installation and commissioning.

Always request a detailed quote from your carbonization equipment manufacturer that lists every component of the system.

How Do You Handle the Smoke Produced During the Process to Meet Environmental Standards?

Modern industrial carbonization is not a smoky process. A smokeless charcoal kiln works by intelligently managing the by-products of pyrolysis, turning a pollution problem into a fuel source.

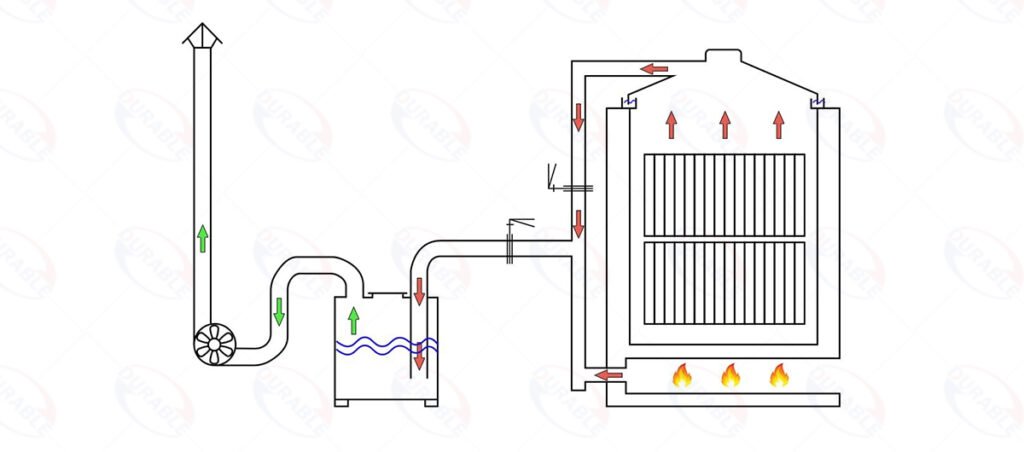

A modern furnace does not release smoke; it consumes it. The “smoke” is actually a mix of steam, condensable liquids (tar and acids), and flammable syngas. Here is how a modern system achieves clean operation and meets environmental standards:

- Condensation: The initial smoke stream is passed through a condenser. The steam and liquids turn into wood vinegar and tar, which are collected. This removes a large portion of the pollutants.

- Purification: The remaining gas, which is the syngas, is passed through purifiers to remove any remaining tar and dust particles.

- Recycling: This clean, flammable syngas is then piped directly back to the furnace’s combustion chamber. It is burned as the primary fuel to provide the heat for the ongoing carbonization process.

Because all the combustible gas is burned cleanly at high temperatures, the only thing that comes out of the final chimney is colorless, odorless water vapor and carbon dioxide, similar to a natural gas boiler.

How to Adjust the Carbonization Process for Different Raw Materials?

Different raw materials have different densities, structures, and chemical compositions. To get the best results, you must adjust your carbonization process accordingly.

You must adapt the process to the material’s properties. A one-size-fits-all approach will lead to poor quality and inefficiency. Here are some general guidelines for common materials:

- Wood Logs/Blocks: This is a classic material for wood carbonization. Because of their large size and density, they require a longer carbonization time and a slower heating rate to ensure the inside is fully carbonized without the outside turning to ash.

- Coconut Shells: Coconut shell charcoal is a premium product known for its high density and heat value. Due to its hardness, it typically requires a higher final carbonization temperature (often >600°C) to achieve its full potential and high fixed carbon content.

- Biomass Briquettes (Sawdust, Straw): Since these are already uniform in size and density, they carbonize very evenly. The process is often faster than with natural wood logs. They are an ideal feedstock for a continuous furnace.

- Sludge/Other Wastes: Sludge carbonization is a growing application for waste management. These materials often have very high initial moisture content and require a powerful pre-drying stage. The carbonization process itself is focused on volume reduction and pathogen destruction.

What Are Some Methods to Reduce Operational Costs and Labor Dependency in Mass Production?

In commercial charcoal production, your long-term profitability depends on keeping your operational costs low. The biggest costs are typically labor and fuel.

Here are the key strategies to reduce costs:

- Automate Fuel Supply: The single biggest cost-saver is using a furnace with an efficient syngas recycling system. This practically eliminates your external fuel costs after the initial start-up.

- Automate Material Handling: Use conveyor belts, screw feeders, and automated loading/unloading systems to move material. This drastically reduces the need for manual labor, lowering your payroll and improving safety. A continuous furnace is the peak of this automation.

- Monetize Your By-products: Do not treat wood vinegar collection as a waste disposal problem. Treat it as a second product line. Purified wood vinegar can be sold to the agricultural sector, creating a new revenue stream that offsets your operational costs.

- Optimize Your Layout: A smart plant layout that minimizes the distance materials need to travel saves energy (electricity for conveyors) and time.

FAQ

Question 1: Which type of carbonization furnace is the most profitable?

The most profitable furnace is the one that best matches your scale and raw material. For medium to large scale, a hoisting furnace offers a great balance of investment and efficiency. For very large-scale, automated operations, a continuous furnace provides the lowest operational cost per ton, leading to the highest long-term profitability.

Question 2: Is industrial charcoal production environmentally friendly?

Yes, when done with modern equipment. A modern industrial furnace captures and burns its own smoke (syngas) for fuel, resulting in very clean emissions. It also turns waste biomass, which would otherwise rot and release methane (a potent greenhouse gas), into stable carbon (charcoal), a form of carbon sequestration.

Conclusion: Your Success is Built on an Efficient System

To succeed in industrial charcoal production, you must shift your mindset. You are not simply “burning wood”; you are managing a controlled thermochemical process. Your profitability is not determined by the size of your furnace, but by the efficiency of your entire system—from material handling and downtime management to energy recycling and by-product monetization. By choosing the right technology and focusing on building a balanced, automated production line, you can create a highly profitable and sustainable business that turns waste into valuable resources.

About Durable

At Durable, we are experts in high-temperature industrial processing. We engineer and build complete, integrated charcoal production lines that are designed for efficiency, reliability, and environmental compliance. We understand that every project is unique, and we work with you to design a system perfectly tailored to your raw materials and business goals. From initial planning to final commissioning, our team is here to ensure your investment is a success.

Are you ready to build a state-of-the-art commercial charcoal plant? Contact our engineers today for a comprehensive consultation and a detailed project proposal.

Durable Machinery

Durable Machinery