Silica Sand Dryer Guide: How to Choose the Right Model and Avoid Costly Losses

Choosing a silica sand dryer is a critical investment for your plant. Unlike drying common minerals, the silica sand drying process demands extreme precision. The final moisture content of silica sand is not just a target; it is a strict quality requirement for high-value industries like glass, foundry, and electronics. Selecting the wrong dryer can lead to uneven drying, product contamination, and ultimately, massive financial losses from rejected batches.

This silica sand dryer guide is designed to walk you through the essential factors in silica sand dryer selection. We will help you understand the different technologies, how to minimize dryer energy consumption, and how to ensure the purity of your final product. Making the right choice from the start ensures high product quality, low operating costs, and a strong return on your investment.

Table of Contents

- Why Is the Final Moisture Content of Silica Sand So Critical?

- Rotary vs. Fluid Bed: Which Dryer Is Best for Your Sand?

- What’s the Smartest Heat Source to Minimize Operating Costs?

- How Do You Prevent Contamination of High-Purity Sand?

- What Other Equipment Do You Need for a Complete Line?

- How to Get an Accurate Quote from a Manufacturer?

- Common Questions About Silica Sand Dryers

- Summary: Your Partner in High-Quality Sand Production

- About Durable

- Get a Professional Solution for Your Plant

Why Is the Final Moisture Content of Silica Sand So Critical?

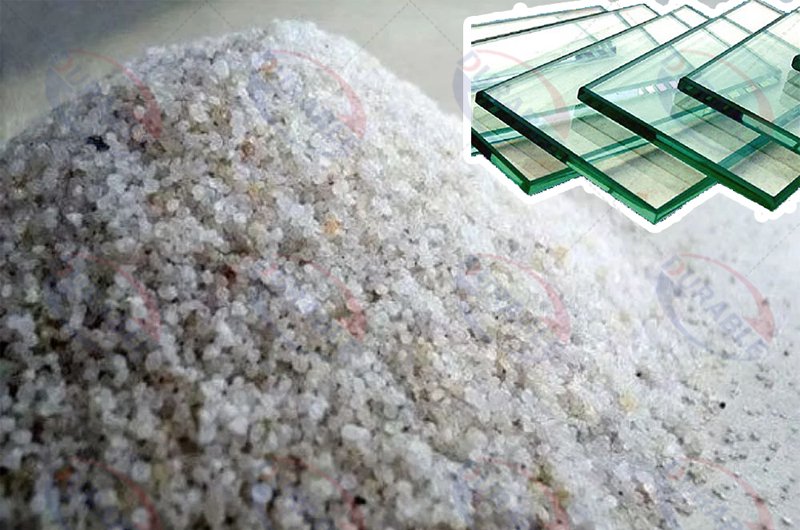

Silica sand, or quartz sand, is a crucial raw material where consistency is key. Industries that use it have zero tolerance for moisture variations.

- Glass Manufacturing: For glass sand drying, even a tiny amount of residual moisture (target is often <0.1%) can cause bubbles and imperfections, rendering the final glass product useless.

- Foundry Casting: In foundry sand drying, precise moisture control is essential for creating strong, stable molds. Inconsistent moisture can lead to casting defects, which are extremely costly to fix.

- Electronics and Solar: For high-purity quartz used in semiconductors and solar panels, any moisture can interfere with complex chemical processes and lead to component failure.

Uneven drying means an entire batch of sand could be rejected by your customer. This is why investing in a dryer that provides precise, uniform heating is not a luxury—it is a necessity to avoid catastrophic financial loss.

Rotary vs. Fluid Bed: Which Dryer Is Best for Your Sand?

Choosing between the main types of silica sand dryers depends on your material’s particle size, your capacity needs, and your final product requirements.

Triple-Pass Rotary Dryer

The three-pass dryer is often the workhorse for silica sand. The material travels through three concentric cylinders, effectively extending its travel distance in a compact machine.

- Best for: A wide range of particle sizes, higher moisture removal, and large capacities.

- Advantages: High thermal efficiency due to its long material residence time. It is robust, reliable, and excellent for reducing initial moisture from over 15% down to less than 1%. Its gentle tumbling action also minimizes particle breakage.

Fluid Bed Dryer

A fluid bed dryer passes hot air up through a perforated plate, causing the sand to behave like a fluid. This provides extremely fast and uniform heat transfer.

- Best for: Fine, uniformly sized particles and applications requiring extremely low final moisture content (e.g., <0.05%).

- Advantages: Very efficient for low moisture removal and provides a very consistent final product. It is ideal as a final-stage “polishing” dryer after a primary rotary dryer.

| Dryer Type | Best Application | Key Advantage | What This Means For You |

|---|---|---|---|

| Triple-Pass Rotary | General purpose, various particle sizes, high initial moisture | High Thermal Efficiency | Lower fuel consumption, ideal for primary drying stage. |

| Fluid Bed | Fine, uniform particles, ultra-low final moisture | Extremely Uniform Drying | Guarantees consistent quality for the most demanding applications. |

What’s the Smartest Heat Source to Minimize Operating Costs?

Energy is the largest operating cost in any drying operation. Your choice of heat source should be based on what is cheapest and most available at your location.

- Natural Gas: This is the preferred choice for high-purity applications. It provides clean, controllable heat, which is essential to prevent contamination of the silica sand. While the fuel can be expensive, the purity it guarantees is often non-negotiable.

- Coal or Biomass: If using an indirect heating method (where the combustion gases do not contact the sand), these can be very cost-effective fuel sources. A heat exchanger is used to generate clean hot air. This adds to the initial capital cost but can significantly reduce long-term fuel expenses.

- Diesel/Oil: A viable option in areas where natural gas is not available. It provides good temperature control but is often more expensive than other options.

Careful analysis of your local fuel costs is crucial. The savings from choosing the right heat source will impact your profitability for years to come.

How Do You Prevent Contamination of High-Purity Sand?

For high-purity silica sand, preventing contamination during drying is just as important as removing moisture. Any foreign material, especially iron, can ruin the product.

- Stainless Steel Construction: For the most sensitive applications, the internal parts of the dryer that come into contact with the sand should be made from stainless steel. This prevents iron contamination from the machine itself.

- Indirect Heating: Using a heat exchanger or a clean fuel like natural gas ensures that the byproducts of combustion (ash, soot) do not mix with your sand. For foundry sand drying, this is a standard requirement.

- Sealed System: The entire drying line, from the feed inlet to the product outlet, must be properly sealed. This prevents dust and other airborne contaminants in the plant from entering the system.

Discuss your purity requirements with your dryer manufacturer. A reputable supplier will understand these needs and design a system with the right materials and configurations to protect your product’s value.

What Other Equipment Do You Need for a Complete Line?

A silica sand dryer is the heart of the system, but it doesn’t operate alone. You must budget for the essential auxiliary equipment that makes the entire line functional and compliant.

- Feeding and Discharging Equipment: This includes belt conveyors, bucket elevators, and vibrating feeders to move the sand into and out of the dryer smoothly.

- Environmental Dust Removal Equipment: This is mandatory. A high-efficiency dust collection system, typically a cyclone followed by a baghouse filter, is required to capture the fine silica dust. This not only ensures compliance with environmental regulations but also improves workplace safety.

- Control System: A PLC control system allows for precise monitoring and adjustment of temperature, feed rate, and airflow, which is critical for achieving a consistent final moisture content.

How to Get an Accurate Quote from a Manufacturer?

To receive a precise and useful proposal from a dryer manufacturer like us, you need to provide clear information about your project. The more detail you give, the better the solution we can design for you.

Be prepared to share the following:

- Material Type: What kind of silica sand are you drying? (e.g., glass sand, foundry sand, frac sand).

- Processing Capacity: How many tons per hour do you need to process?

- Moisture Content: What is the initial moisture (%) of the wet sand and the target final moisture (%) of the dried sand?

- Particle Size: What is the size distribution of your sand?

- Heat Source: What fuel do you plan to use? (e.g., natural gas, coal, diesel).

- Purity Requirements: Are there specific requirements for purity, such as needing stainless steel contact parts?

Providing this data will allow us to engineer the right size and type of dryer for your needs, ensuring the quote you receive is realistic and tailored to your plant. Check out our sand dryer solutions for more information.

Common Questions About Silica Sand Dryers

Question 1: What is the typical energy consumption of a three-pass silica sand dryer?

A: A well-designed three-pass dryer is highly efficient. For example, to evaporate one ton of water, it typically consumes about 600,000 to 700,000 kcal of heat, which is significantly lower than a single-drum dryer. The exact consumption depends on the initial moisture and system configuration.

Question 2: Can a single dryer handle different types of sand?

A: Yes, a rotary dryer is quite versatile. However, the system must be designed for the most demanding sand type (e.g., the one with the highest moisture or finest particles). Adjustments to temperature and feed rate can then be made for other sand types.

Question 3: How long does a high-quality silica sand dryer last?

A: With proper maintenance, a heavy-duty dryer from a reputable manufacturer can last for 15-20 years or more. Key maintenance tasks include regular lubrication of bearings and gears, and inspection of wear parts like the internal flights and seals.

Summary: Your Partner in High-Quality Sand Production

Choosing the right silica sand dryer is a strategic decision that directly impacts your product quality, operational costs, and profitability.

- Prioritize Product Quality: The dryer must deliver precise and uniform moisture content to avoid costly rejections.

- Select the Right Technology: Choose between a three-pass rotary or fluid bed dryer based on your specific sand and requirements.

- Optimize for Energy Costs: Select the most economical fuel source for your location.

- Never Compromise on Purity: Ensure your system is designed to prevent contamination.

By carefully considering these factors, you can select a drying system that serves as a reliable and profitable foundation for your business for years to come.

About Durable

Since 2001, Durable has been a specialized Chinese manufacturer of industrial drying systems and mineral processing equipment. We have extensive experience in designing and building custom silica sand dryer lines for clients worldwide. Our factory-direct approach and full-service support, from initial design to installation and commissioning, ensure you receive a high-performance solution that meets the strictest quality standards.

Get a Professional Solution for Your Plant

Ready to discuss your silica sand drying needs? Contact our engineering team today. Provide us with your project specifications, and we will develop a detailed technical proposal and a competitive quote for a system designed to maximize your product quality and profitability.

Durable Machinery

Durable Machinery