Single Drum vs. Three-Pass Dryer: Which One Should You Choose?

As an engineer at Durable, one of the most common questions I get from clients is about choosing between a single drum dryer and a three-pass dryer. On the surface, they seem similar, but choosing the wrong one can cost you thousands in wasted energy or lead to a system that simply doesn’t work for your material. This is not just a technical choice; it is a major financial decision. This guide will break down the key differences between these two workhorses of the industry. We will help you understand which one is the smart investment for your specific needs.

Table of Contents

- How Do Their Structures Affect My Plant Layout?

- Which Dryer is More Energy Efficient?

- How Do They Handle Different Materials?

- Which Materials Are Best for Each Dryer?

- Which Machine Offers Better Drying Performance?

- Which is Easier to Operate and Maintain?

- What Other Equipment Investments Are Necessary?

- FAQs

- Conclusion and Next Steps

- About Durable

How Do Their Structures Affect My Plant Layout?

The most obvious difference between a single drum and a three-pass dryer is their physical size and shape. This has a huge impact on how you design your facility.

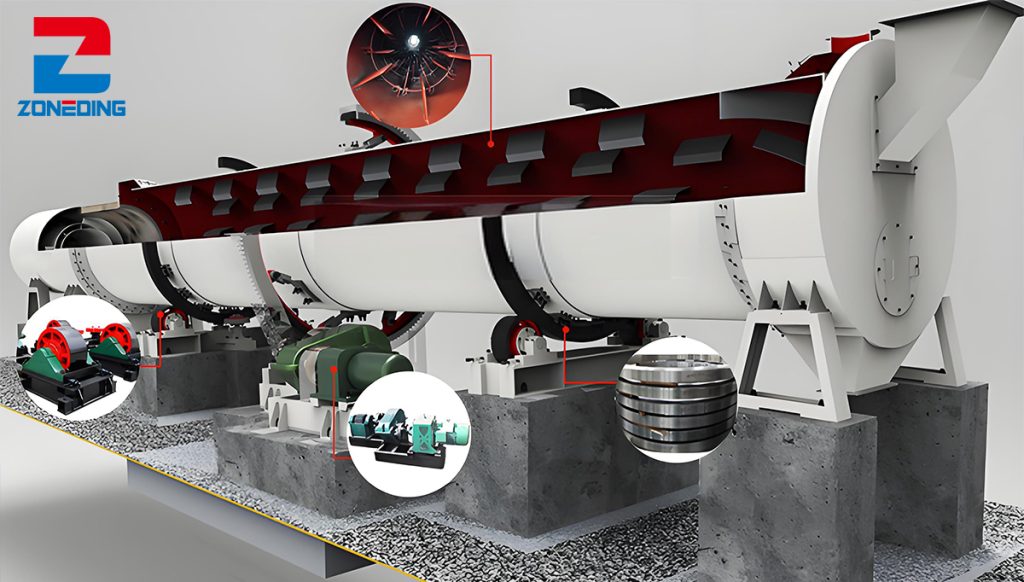

A single drum dryer is exactly what it sounds like: one long, slightly sloped cylinder. To get enough drying time, the material has to travel the entire length of this single tube. This means the machine is very long and takes up a large amount of floor space. It is a simple, robust design, but it is not compact.

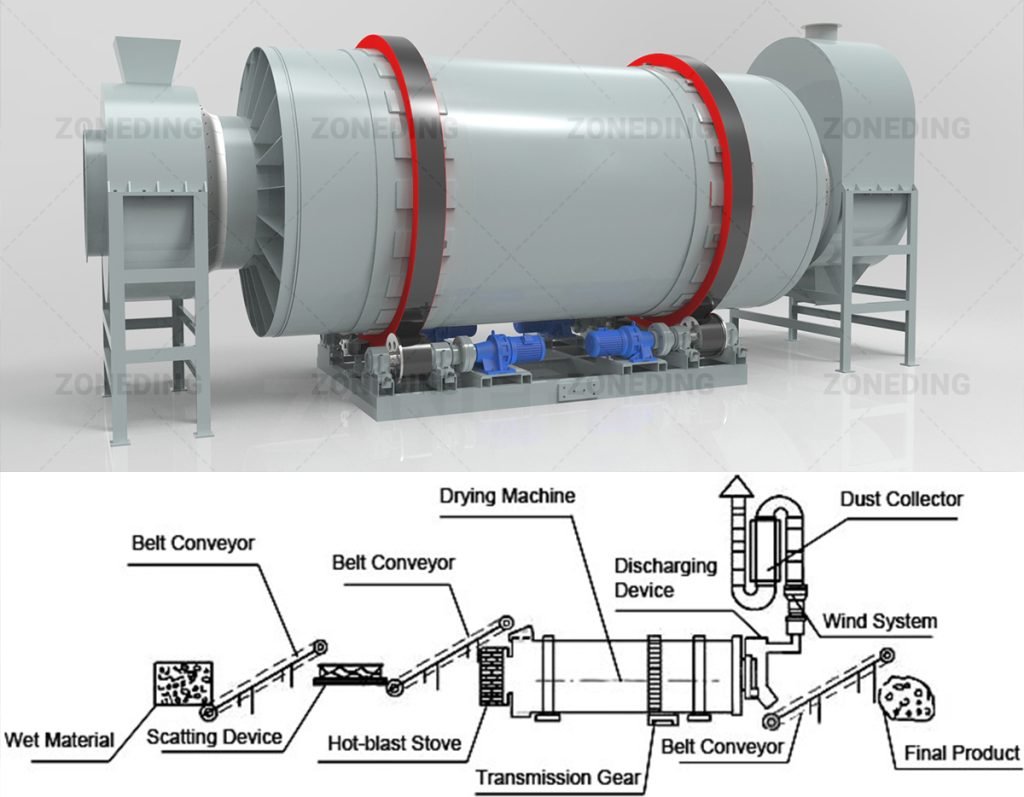

A three-pass dryer is much smarter in its design. It uses three concentric drums, one nested inside the other. Your material is fed into the innermost drum, travels to the end, then gets directed back through the middle drum, and finally travels through the outer drum. This means the material travels three times the length of the machine’s body. For a plant with limited space, this compact design is a major advantage, saving valuable square footage.

Which Dryer is More Energy Efficient?

This is where the difference between a single drum and a three-drum dryer becomes a critical financial issue. Your fuel bill is the largest part of your operating cost, and the two designs have very different levels of thermal efficiency.

The single drum dryer is less efficient. Hot gas flows through the drum once and then exits. The exhaust gas temperature is often still very high, which means a lot of heat is wasted. The large, single shell also loses a lot of heat to the surrounding environment.

The three-pass dryer is much more efficient. It can reduce your energy consumption by 30-50%. The triple-pass design forces the hot gas to stay in contact with the material for a much longer time. This allows more heat to be transferred to your material before the gas is exhausted. The inner drums are also insulated by the outer ones, which drastically reduces heat loss. While it costs more upfront, the fuel savings can be massive over the life of the machine. For more details on this design, you can review our Triple-Pass Rotary Drum Dryer specifications.

How Do They Handle Different Materials?

The way the material moves inside the dryer is also very different. This determines which dryer is suitable for your specific product.

In a single drum dryer, the material is lifted by steel fins and tumbles through a high-velocity stream of hot air. This is a straightforward and powerful process. It is excellent at handling large, lumpy, or even sticky materials like coal, mineral ores, and slag.

In a three-pass dryer, the movement is gentler. The material is lifted and scattered multiple times in each of the three drums. This design is perfect for finer and more granular materials like sand, mineral powders, or sawdust. These fine materials could be blown right out of a high-velocity single-drum dryer, leading to major product loss.

At-a-Glance Comparison

| Feature | Single Drum Dryer | Three-Pass Dryer | What This Means for You |

|---|---|---|---|

| Footprint | Very Large, Long | Compact, Short | Saves valuable plant space. |

| Thermal Efficiency | Lower | High (Saves 30-50% on fuel) | Significantly lower long-term operating costs. |

| Material Handling | Robust, for heavy/lumpy materials | Gentle, for fine/granular materials | You must match the dryer to your material type. |

| Initial Price | Lower | Higher | A classic trade-off between upfront cost and long-term savings. |

Which Materials Are Best for Each Dryer?

Based on these differences, the application for each dryer is quite clear. You must choose the right tool for the job. An incorrect choice will lead to poor performance and inefficiency.

A Single Drum Dryer is the best choice for:

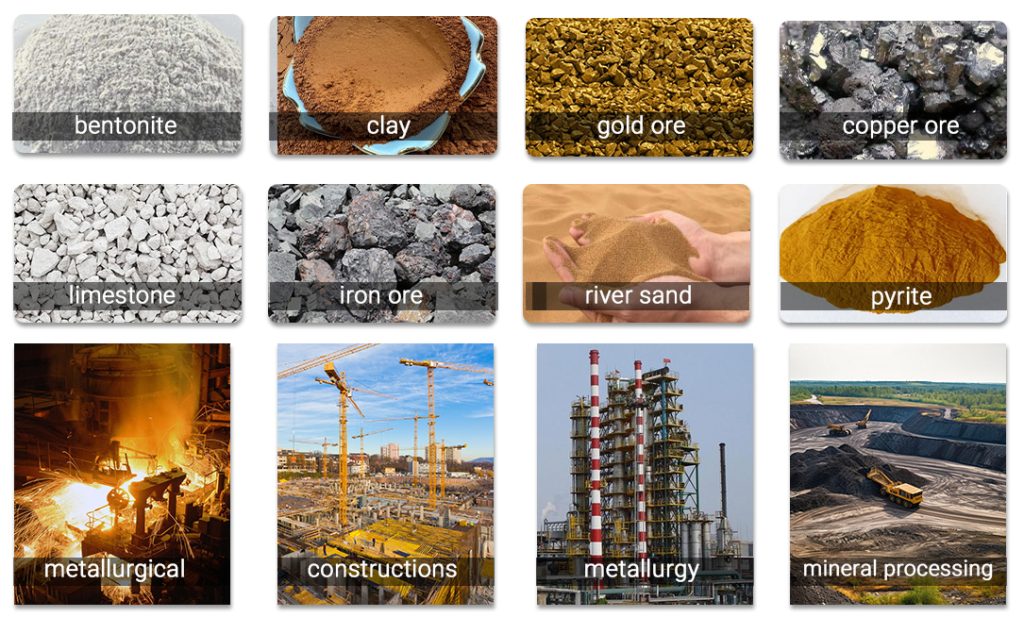

- Heavy-duty materials: Coarse coal, mineral ores, limestone, clay, and slag.

- Large particles: It can handle bigger chunks of material without issue.

- Very high moisture removal: It is effective at removing large amounts of water from very wet materials.

- Projects with a lower initial budget: When the upfront capital cost is the most important factor.

A Three-Pass Dryer is the best choice for:

A Three-Pass Dryer is the best choice for:

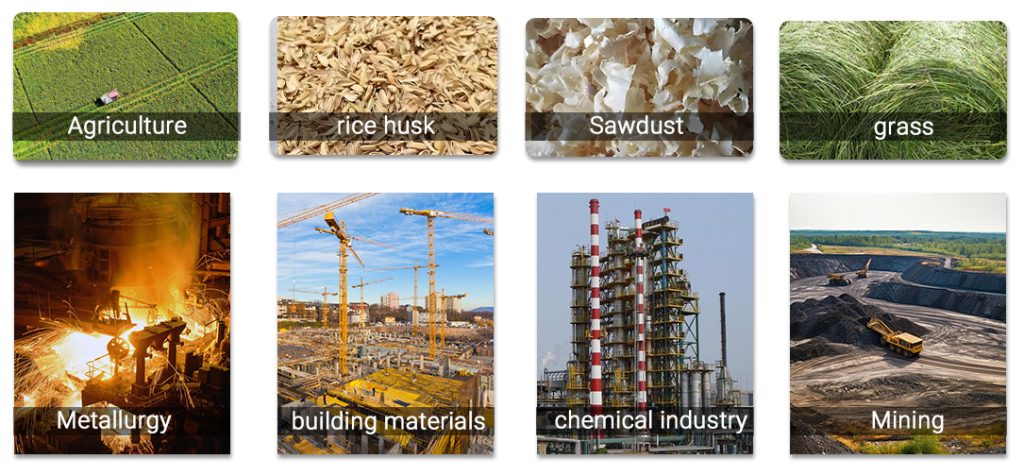

- Fine granular materials: This is the ideal choice for a Sand Dryer, as well as for mineral powders, sawdust, and fertilizers.

- Energy-conscious operations: If you are in a region with high fuel costs, the long-term savings are significant.

- Space-constrained plants: When you simply do not have the room for a long single-drum machine.

- Products needing precise moisture control: The uniform drying produces a very consistent final product.

Which Machine Offers Better Drying Performance?

Drying efficiency is about more than just fuel savings. It is also about the quality and consistency of your final product. The right dryer will give you a uniformly dried material, batch after batch.

The three drum dryer generally offers superior drying performance for suitable materials. Because the material is repeatedly lifted and scattered over a much longer travel path, every particle is exposed to the hot air more evenly. This results in a very consistent final moisture content across the entire batch. This is crucial for high-spec products like silica sand or fertilizers where uniformity is a key quality parameter. The compact dryer footprint also simplifies plant layout.

The single drum dryer is highly effective for its intended purpose: removing large amounts of water from bulk materials. Its simple and robust design is very reliable for heavy-duty applications. While it may not offer the same level of precision moisture control as a three-drum model, it provides the raw power needed for drying high-tonnage, high-moisture products where the primary goal is bulk water removal rather than fine-tuned moisture content.

Which is Easier to Operate and Maintain?

Simplicity often translates to easier maintenance, which is an important consideration for any plant manager.

A single drum dryer is mechanically simpler. It has fewer complex components. The bearings, drive system, and internal flights are straightforward and have been used in the industry for over a century. This makes troubleshooting and maintenance relatively easy for most mechanical teams. It is a time-tested, reliable design that is known for its durability.

A three drum dryer is a more complex piece of machinery. The nested drums require precise alignment and support systems. While modern designs from reputable manufacturers are very reliable, maintenance can be more involved. However, these systems are typically equipped with advanced PLC controls that automate the drying process, making day-to-day operation very simple. The system can automatically adjust temperature and feed rate to maintain a consistent output.

What Other Equipment Investments Are Necessary?

Remember, you are not just buying a dryer drum. You are investing in a complete drying system. Both single and three drum dryers require the same set of essential auxiliary equipment to function.

- Heat Source: A furnace or burner (e.g., coal-fired, gas, biomass) to generate the hot air.

- Feeding Equipment: Hoppers and conveyors to provide a steady, controlled feed of wet material.

- Discharging Equipment: Conveyors and seals to handle the hot, dried product.

- Dust Collection System: A cyclone and baghouse filter are mandatory to control emissions and recover fine product.

- Control Panel: A PLC system to monitor and control the entire process.

These auxiliary systems represent a significant portion of the total project cost and must be included in your budget from the start.

FAQs

1. Is a single-drum dryer always cheaper?

Yes, the initial purchase price for a single-drum dryer is almost always lower than for a three-pass dryer of the same capacity. However, you must calculate the total cost of ownership, which includes your fuel costs over several years.

2. Can a three-pass dryer handle sticky materials like clay?

Generally, no. The complex internal structure of a three-pass dryer can get clogged by very sticky materials. A single-drum dryer, sometimes fitted with special chain-breakers inside, is a much better solution for sticky products like wet clay or mineral sludge.

3. How do I decide if the extra cost for a three-pass dryer is worth it?

Calculate your expected annual fuel cost with a single-drum dryer. Then, reduce that cost by 30-40% to estimate the savings with a three-pass dryer. You can then see how many years it will take for the fuel savings to pay back the higher initial investment.

Conclusion and Next Steps

The choice between a single drum dryer and a three-pass dryer is a choice between a lower upfront cost and a lower long-term operating cost. The single-drum is a simple, robust workhorse for heavy materials. The three-pass is a modern, highly efficient machine perfect for granular materials where energy savings and a compact footprint are critical. The right decision depends entirely on your material, your budget, your fuel costs, and your plant layout.

Understanding these key differences is the first step. The next is to discuss your specific project with an experienced engineer.

About Durable

We are Durable Machine, a professional manufacturer of industrial drying and mineral processing equipment since 2001. We specialize in providing complete, customized B2B solutions for large-scale projects worldwide. As a factory-direct seller, we offer competitive pricing and full-service support, from initial material testing and plant design to manufacturing, on-site installation, and lifelong after-sales service. Our robust equipment is trusted by industrial clients in over 120 countries.

Contact us today with your project specifications, and we will provide a detailed, no-obligation proposal to help you make the smartest choice.

Durable Machinery

Durable Machinery