Sludge Dryer: The Green Solution for Global Sludge Disposal

The world is facing a sludge crisis. Every city and every factory produces it, a wet, heavy, and hazardous byproduct of wastewater treatment. For too long, the solution was to simply move the problem somewhere else. At Durable, we see this differently. We believe that sludge disposal is not an end-of-pipe problem, but a resource recovery opportunity. The sludge dryer is the key technology that makes this possible.

A modern sludge dryer does more than just remove water. It transforms a costly liability into a valuable asset. It is the heart of a circular economy for sludge treatment, enabling you to reduce costs, protect the environment, and turn waste into worth. This guide will explain how.

Table of Contents

- What’s Wrong with Traditional Sludge Disposal Methods?

- How Energy-Intensive is a Sludge Dryer?

- How Do You Dry Sticky, High-Moisture Sludge Without Clogging?

- What Can You Do With Dried Sludge? (Sludge Resource Recovery)

- How Do You Control Odor and Dust During Drying?

- What’s in a Complete Sludge Drying Production Line?

- Common Questions About Sludge Drying

- Summary and Recommendations

- About Durable

- Contact Us

What’s Wrong with Traditional Sludge Disposal Methods?

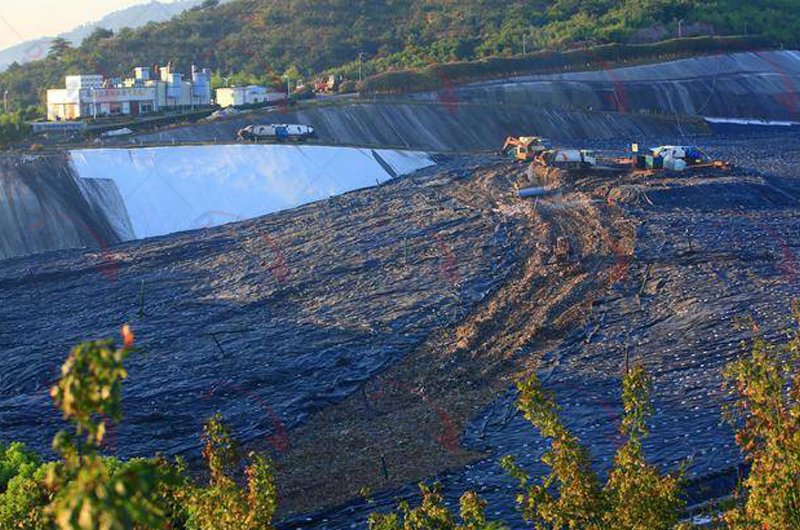

The old ways of handling sludge—landfilling and incineration—are becoming unsustainable, expensive, and environmentally unacceptable. If you are managing a treatment plant, you are already feeling the pressure from rising sludge disposal fees and stricter regulations.

- Landfilling: This is the most common but most flawed method. You are essentially paying to transport and bury water, as wet sludge is 80-99% water. This leads to massive transportation costs, rapid consumption of valuable landfill space, and significant environmental risks. Wet sludge in a landfill can leak contaminated liquid (leachate) into groundwater and release methane, a greenhouse gas 25 times more potent than CO2.

- Incineration (of Wet Sludge): Burning wet sludge requires an enormous amount of energy simply to boil off the water before the solids can even begin to combust. This makes it incredibly expensive and energy-intensive, with a large carbon footprint and the need for complex air pollution control systems.

These methods treat sludge as a problem to be hidden. A sludge dryer treats it as a solution waiting to be unlocked.

How Energy-Intensive is a Sludge Dryer?

This is the first question every plant manager asks, and it’s a critical one. The answer is: it depends entirely on how intelligently you source your heat. While evaporating water always requires energy, a modern sludge drying system is designed for maximum efficiency.

The truly “green” solution lies in low-temperature sludge drying technology that is designed to use waste heat. This is a game-changer for the economics of sludge drying cost.

Here are your primary heat source options:

- Waste Heat (The Ultimate Green Solution): Many facilities, like power plants, cement kilns, or large industrial factories, vent huge amounts of low-grade heat (80-150°C) into the atmosphere. A low-temperature belt dryer or paddle dryer can capture this “free” energy and use it to dry your sludge. This turns two waste streams—sludge and heat—into a valuable product.

- Biogas: If your wastewater treatment plant has an anaerobic digester, you are already producing biogas (methane). This biogas can be used to fire a furnace, creating a closed-loop, self-sustaining energy system for your drying operation.

- Natural Gas / Other Fuels: If waste heat or biogas is unavailable, highly efficient furnaces can be used. Modern sludge drying equipment from manufacturers like Durable is designed to maximize heat transfer and minimize fuel consumption, keeping your operational costs as low as possible.

How Do You Dry Sticky, High-Moisture Sludge Without Clogging?

Municipal sludge and many types of industrial sludge are notoriously sticky, especially as they transition from wet to semi-dry. This “sticky phase” can cause material to build up, clog the dryer, and bring your entire operation to a halt. As experienced engineers, we solve this problem with smart design.

The key is mechanical agitation and pre-conditioning:

- Advanced Internal Design: The inside of a high-quality sludge dryer is not just an empty drum. It is equipped with specially designed agitators. For example, our paddle dryers use interlocking, heated paddles that not only transfer heat but also constantly chop, turn, and break up the sludge. This prevents clumps from forming and keeps the material moving freely.

- Back-Mixing: This is a simple but highly effective technique. A portion of the final, dry, granular product is mixed back in with the incoming wet sludge at the dryer inlet. This immediately lowers the overall moisture content and stickiness of the feed material, allowing it to flow smoothly through the system without buildup.

- Mechanical Dewatering First: Before thermal drying, sludge should be mechanically dewatered using equipment like a screw press or centrifuge. This can reduce the moisture content from 99% down to 75-80%. This step alone dramatically reduces the amount of water that the thermal dryer has to evaporate, saving significant energy and reducing the load on the machine.

What Can You Do With Dried Sludge? (Sludge Resource Recovery)

This is where the magic happens. The sludge dryer is the key that unlocks the value within the waste. Sludge resource recovery turns a disposal cost into a potential revenue stream. The dry, sterile, granular product is no longer waste; it is a feedstock.

| End Use | Description | Your Key Benefit |

|---|---|---|

| Biofuel | Dried sludge has a calorific value similar to low-grade coal. It can be used in cement kilns or power plants. | Reduces reliance on fossil fuels; can be sold as an alternative energy source. |

| Fertilizer / Soil Conditioner | The drying process kills pathogens, creating sterile “biosolids” rich in nitrogen and phosphorus. | Creates a valuable agricultural product; reduces the need for chemical fertilizers. |

| Construction Material | Can be used as a lightweight aggregate in the production of bricks, blocks, or ceramsite. | Turns waste into building materials; creates a new product line. |

| Landfill Cover | The stable, inert material is excellent for daily cover at landfills, preventing odors and pests. | Provides a beneficial reuse even if other markets are not available. |

How Do You Control Odor and Dust During Drying?

A sludge drying plant must be a good neighbor. Controlling foul odors and dust is non-negotiable for both environmental compliance and community acceptance. This is achieved through a fully integrated and enclosed system.

Odor treatment and dust control involve three key principles:

- Completely Enclosed System: The entire process, from the sludge feeder to the final product discharge, is sealed. The equipment, including the sludge dryer itself, operates under a slight negative pressure. This means that if there are any small leaks, clean air is drawn into the system rather than odorous air leaking out.

- High-Efficiency Dust Collection: The air stream leaving the dryer carries fine dust particles. This air is sent to a high-efficiency baghouse or cyclone dust collector, which captures over 99% of the particulate matter.

- Dedicated Odor Treatment Unit: The cleaned, dust-free air is still hot, humid, and smelly. It is ducted to a dedicated odor treatment system before being released. Common methods include passing the air through a condenser (to cool it and remove water) followed by a bio-filter, activated carbon tower, or chemical scrubber to eliminate the odorous compounds.

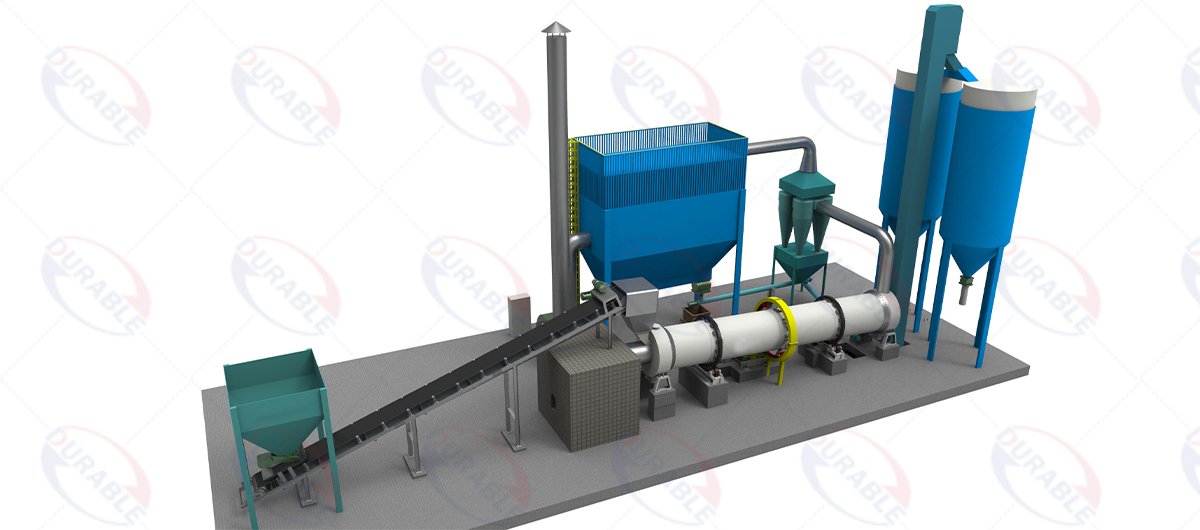

What’s in a Complete Sludge Drying Production Line?

A successful sludge drying operation is more than just the dryer itself; it’s a complete, engineered system. A typical production line includes:

- Wet Sludge Feeding System: A hopper or silo to receive the dewatered sludge, and a screw pump to feed it into the dryer at a controlled rate.

- Heat Source: A furnace, hot air stove, or heat exchanger to generate or supply the hot air for drying.

- Sludge Dryer: The core machine, selected based on your sludge type and capacity needs (e.g., paddle dryer, belt dryer).

- Discharge and Cooling System: A sealed conveyor to transport the hot, dry product, often incorporating a cooling screw to lower its temperature for safe storage.

- Dust Collection System: A baghouse or other collector to capture dust from the airstream.

- Odor Treatment System: A condenser and scrubber/filter to clean the exhaust air.

- Final Product Storage: Silos to store the dry, granular product.

- Central PLC Control System: A control panel that allows an operator to monitor and manage the entire line, from feed rate to temperature, ensuring optimal performance.

Common Questions About Sludge Drying

Q1: What is the typical sludge drying cost?

A: The cost varies greatly based on your heat source. If you can use “free” waste heat, the operational sludge drying cost is extremely low, consisting mainly of electricity for motors. If using natural gas, costs are higher but still far less than landfilling fees in many regions.

Q2: Can you dry both municipal sludge and industrial sludge?

A: Yes. Our sludge drying equipment can be adapted for a wide range of sludge types. However, industrial sludge (e.g., from chemical plants, paper mills) may require specific material considerations (like stainless steel construction) or different temperature profiles than municipal sludge. A thorough analysis of your sludge is the first step in designing the right system.

Q3: What level of sludge volume reduction can I expect?

A: You can expect a dramatic sludge volume reduction of 75-90%. A typical dryer takes sludge with 80% moisture content and reduces it to a final product with 10% moisture, cutting the total volume and weight by a factor of four or more.

Q4: Is low-temperature sludge drying effective at killing pathogens?

A: Absolutely. While it doesn’t use scorching heat, low-temperature sludge drying pasteurizes the sludge by holding it at a specific temperature (e.g., 70-90°C) for a prolonged period. This process is highly effective at destroying pathogens and creating a safe Class A Biosolid product.

Summary and Recommendations

The era of treating sludge as a valueless waste is over. The sludge dryer is the enabling technology for a modern, sustainable, and profitable sludge management strategy.

By implementing an efficient sludge drying system, you can:

- Drastically reduce your disposal volume and costs.

- Eliminate environmental risks associated with landfills.

- Control odors and dust to ensure compliance and community acceptance.

- Create valuable products like biofuel and fertilizer through sludge resource recovery.

This is not just an environmental decision; it is a sound economic one. It transforms a major operational liability into a center of efficiency and value.

About Durable

We are Durable, a leading Chinese manufacturer of mineral processing and industrial drying equipment since 2001. We specialize in B2B solutions and have extensive experience in designing and building complete sludge treatment systems. Our sludge dryers and production lines are operating in over 120 countries, helping municipalities and industries around the world adopt greener, more cost-effective disposal methods. As a direct manufacturer, we provide tailored engineering, competitive pricing, and full-service support.

Contact Us

Are you ready to transform your sludge disposal challenges into a resource recovery opportunity? Contact our team of drying experts today. We will analyze your specific sludge, evaluate your facility’s energy profile, and design a complete sludge drying solution that meets your environmental goals and financial objectives.

Durable Machinery

Durable Machinery