Sludge Dryers: The Solution for Municipal Sewage Sludge Treatment

As an engineer with decades of experience in thermal processing, I can tell you that for most Wastewater Treatment Plants (WWTPs), their biggest headache is sludge. The cost of municipal sewage sludge treatment and disposal is a massive, uncontrolled expense. You are paying huge sums of money to haul and bury what is essentially just water. But there is a better way. A Sludge Dryer is the key to transforming this problem. It is a powerful tool for sludge drying that turns a costly waste into a valuable resource.

This guide is our expert advice on how you can take control of your sludge disposal cost. We will explain how a modern sludge dryer works, how it achieves massive sludge volume reduction, and how it creates new revenue streams through sludge resource utilization. By the end, you will understand the technology, the real-world costs, and the path to achieving full environmental compliance while boosting your bottom line.

Table of Contents

- Why Is Wet Sludge the Biggest Cost Center for WWTPs?

- How Do Sludge Dryers Reduce Volume by Over 75%?

- What Are the High-Value Uses for Dried Sludge?

- Which Dryer Type Avoids Sticking and Clogging?

- How Does Low-Temp Drying Solve Odor and Dust Problems?

- What Is the Real Energy Cost to Dry One Ton of Sludge?

- What Is Needed for a Complete Sludge Drying System?

- Common Questions About Sludge Drying

- Summary: Turn Your Biggest Cost into a New Asset

- About Durable

- Get a Custom Sludge Treatment Proposal

Why Is Wet Sludge the Biggest Cost Center for WWTPs?

Wet sludge, with a water content of 80%, is the biggest cost center because you are primarily paying to transport and dispose of water. This makes your sludge disposal cost incredibly high and inefficient.

At our company, we have seen this problem firsthand at countless municipal sites. A Wastewater Treatment Plant (WWTP) does a great job of cleaning water, but it creates a byproduct: sludge. Even after mechanical dewatering, this sludge is still about 80% water and only 20% solid material. This means that for every 5 trucks of sludge you send to a landfill, 4 of them are just carrying water. You pay for the fuel to transport that water. You pay for the driver’s time. And most importantly, you pay landfill “tipping fees” that are based on weight. The heavier and more voluminous the material, the more you pay. On top of that, wet sludge is biologically active. It produces foul odors, attracts pests, and is considered a biohazard, which can lead to stricter regulations and even higher handling costs.

How Do Sludge Dryers Reduce Volume by Over 75%?

A sludge dryer works by using thermal energy to evaporate the water from the sludge, reducing the moisture from 80% down to 10% or less. This simple step results in a massive sludge volume reduction of over 75%.

The math behind this is simple but powerful. Let’s start with 100 tons of wet sludge at 80% moisture. This means you have 80 tons of water and 20 tons of solid material. After processing it through a Sludge Dryer, you aim for a final moisture content of 10%. The final product will still contain the original 20 tons of solids. But now, it only holds about 2.2 tons of water. The total weight of your final product is just 22.2 tons. You have eliminated almost 78 tons of water. This is a weight and volume reduction of nearly 78%. This reduction has a direct and immediate impact on your sludge disposal cost. Your transportation costs are cut by more than 75%. Your landfill fees are cut by more than 75%. You have turned 5 truckloads of waste into just 1 truckload of a manageable product.

What Are the High-Value Uses for Dried Sludge?

Beyond just saving on disposal, sludge drying turns waste into a valuable product. Dried sludge has a high calorific value, making it a renewable fuel, and it is rich in nutrients, making it an excellent organic fertilizer.

This is the most exciting part of sludge resource utilization. You stop paying to get rid of a problem and start creating a product that people will pay for. This creates a true circular economy for your Wastewater Treatment Plant (WWTP). The first major use is as a fuel. The sludge calorific value of the dried biosolids is similar to that of lignite or low-grade coal. Cement kilns and some power plants will purchase this material to use as a co-firing fuel, helping them reduce their use of fossil fuels and lower their carbon footprint. The second major use is in agriculture. The heat from the sludge drying process sterilizes the sludge, killing pathogens and making it safe to handle. The resulting dry granules are rich in nitrogen and phosphorus, two key components of fertilizer. This creates a slow-release organic fertilizer that can be sold to farming operations, improving soil health and reducing the need for chemical fertilizers.

| Resource Use | Key Benefit | Potential Revenue Stream |

|---|---|---|

| As a Fuel | High calorific value, reduces fossil fuel use. | Selling to cement kilns, power plants. |

| As a Fertilizer | Rich in N & P, improves soil health. | Selling to agricultural companies. |

| As a Filler | Lightweight and stable material. | Use in brick making or land reclamation. |

Which Dryer Type Avoids Sticking and Clogging?

For the high-moisture, sticky nature of municipal sludge, an indirect heat paddle dryer is the superior choice. Its unique self-cleaning design prevents the sludge from building up and causing blockages.

This is a critical engineering detail we have focused on for years. As sludge dries, it passes through a “sticky phase” between 40% and 60% moisture, where it has the consistency of thick glue. In a standard direct-fired rotary dryer, this sticky material can build up on the inner walls, leading to poor heat transfer, blockages, and even fire risks. A Paddle Dryer, however, is specifically designed to handle this. It works through indirect heating. A hot medium like steam or thermal oil flows through hollow paddles that rotate and mix the sludge. The key is that the paddles are intermeshed. As they rotate, they constantly scrape the surface of each other and the dryer walls. This continuous shearing and scraping action provides a self-cleaning effect that keeps the heat transfer surfaces clean and prevents any buildup. This makes the paddle dryer extremely reliable and efficient for municipal sewage sludge treatment.

How Does Low-Temp Drying Solve Odor and Dust Problems?

Low-temperature sludge drying, especially when using an indirect heat system like a paddle dryer, solves odor and dust issues at the source. It produces a very small volume of exhaust gas, making treatment easy and affordable.

Achieving environmental compliance is non-negotiable. Odor is often the biggest public complaint about a Wastewater Treatment Plant (WWTP). A traditional direct-heat rotary dryer works by blowing massive volumes of hot air over the sludge. This huge volume of air becomes filled with foul-smelling compounds and fine dust particles. Cleaning this large air stream requires a very large, complex, and expensive air pollution control system, often including a thermal oxidizer that burns natural gas. In contrast, low-temperature sludge drying with an indirect paddle dryer is a much cleaner process. Because it heats the sludge by contact, not with hot air, the only exhaust gas is the water vapor boiled off from the sludge, plus a very small amount of non-condensable gas. This low volume of exhaust can be easily treated with a much smaller and cheaper system, such as a simple condenser and a carbon filter. This dramatically reduces both the initial capital cost and the ongoing operational cost of your system.

What Is the Real Energy Cost to Dry One Ton of Sludge?

The real energy cost depends on your local utility prices, but an efficient system typically requires 600-800 kWh of thermal energy and 30-50 kWh of electrical energy to dry one ton of 80% moisture sludge.

Understanding the operational cost is key to calculating your return on investment. The total energy cost for sludge drying has two main parts. The largest part is the thermal energy needed to evaporate the water. The most economical source for this is waste heat from another process, but it can also be supplied by a dedicated boiler using natural gas, biomass, or other fuels. To evaporate the roughly 0.7-0.8 tons of water in one ton of wet sludge, you will need a significant amount of heat. An efficient indirect Sludge Dryer will be much better at transferring this heat to the product with minimal loss. The second part is the electrical energy. This is what powers the motors that turn the dryer’s paddles, as well as the pumps and conveyors that move the material. While smaller than the thermal cost, it is still an important factor. To get an accurate estimate, we would analyze your specific sludge characteristics and local energy prices to calculate a precise cost per ton for your facility.

What Is Needed for a Complete Sludge Drying System?

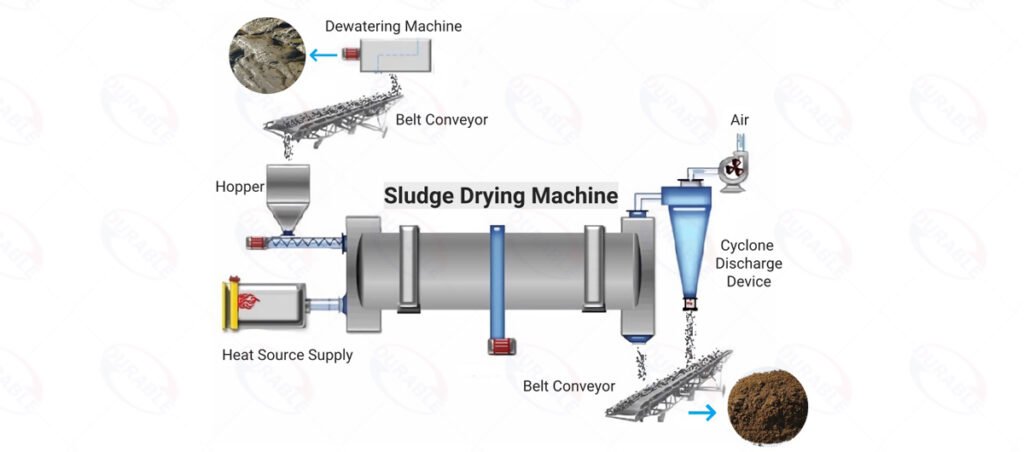

A complete sludge drying system is an integrated plant, not just a single machine. It requires carefully selected ancillary equipment for feeding, heating, cooling, and exhaust treatment to ensure safe and efficient operation.

When you partner with us, we provide an EPC (Engineering, Procurement, and Construction) solution. We look at the entire process from start to finish. A typical system includes several key components working together:

- Dewatering Unit: The process starts here. A screw press or centrifuge takes the sludge from 99% moisture down to 80%.

- Wet Sludge Hopper and Feed Pump: This holds the dewatered sludge and feeds it into the dryer at a steady, controlled rate.

- Heat Source: This could be a natural gas boiler, a Biomass Burner, or a heat exchanger to capture waste heat from your plant.

- The Sludge Dryer: The core of the system, typically a paddle dryer, where the thermal drying takes place.

- Dry Product Discharge System: A cooling screw is essential. It receives the hot, dry product (often over 100°C), cools it to a safe temperature for storage, and prevents dust issues.

- Exhaust Gas Treatment System: This unit condenses the water vapor and treats any remaining odors to ensure you meet all environmental compliance regulations.

- Central Control Panel (PLC): The brain of the operation, which automates the entire system for safe, efficient, and reliable performance.

Common Questions About Sludge Drying

Question 1: What is the difference between sludge dewatering and sludge drying?

Dewatering is a mechanical process, like squeezing a sponge with a press, that typically reduces moisture to around 80%. Drying is a thermal process that uses heat to evaporate the remaining water, reducing moisture to 10% or less.

Question 2: Can the dried sludge be used to power the dryer itself?

Yes, this is possible with an advanced process called gasification. The dried sludge is turned into a syngas, which can then be burned to provide heat for the drying process, creating a highly self-sufficient system.

Question 3: What kind of maintenance does a paddle dryer require?

Paddle dryers are very robust. Routine maintenance includes checking the gearbox oil, inspecting the integrity of the paddles, and ensuring the steam or thermal oil joints are secure. Because they operate at low speeds, wear and tear is minimal.

Summary: Turn Your Biggest Cost into a New Asset

Your municipal sewage sludge treatment does not have to be a drain on your budget. The high sludge disposal cost you are paying today can be drastically reduced. By investing in an efficient Sludge Dryer, you can achieve massive sludge volume reduction, cutting your transport and landfill fees by up to 90%. More importantly, through sludge drying, you begin a process of sludge resource utilization. You can create a valuable, safe, and marketable product that generates new revenue. A modern paddle dryer system is the key to making this transition safely, reliably, and in full environmental compliance.

About Durable

For over 20 years, Durable (Durablemac) has been a global leader in manufacturing industrial processing equipment. We apply our deep expertise in thermal drying from the mining and mineral industries to solve the toughest challenges in sludge management. Our robust and efficient drying systems are helping municipalities and industrial clients around the world turn waste into value.

Get a Custom Sludge Treatment Proposal

Are you ready to take control of your sludge costs? Contact our engineering team today. We will provide a free analysis of your current situation, recommend a custom-designed drying system, and give you a detailed report on your potential cost savings and return on investment. Let us be your partner in building a more sustainable and profitable future.

Durable Machinery

Durable Machinery