Square Continuous Biomass Carbonization Furnace

The Square Continuous Biomass Carbonization Furnace is another mainstream technology for achieving efficient biomass carbonization. It solves the problem of continuous material processing through a static furnace body + internal conveying system. Compared to the rotary drum furnace, it has certain advantages in sealing, footprint, and processing of powdery materials, but it also faces challenges in the durability and maintenance of its internal mechanical structure. The choice of furnace type usually depends on the characteristics of the raw material, the processing capacity, and specific process requirements.

Biomass materials:

wood chips, sawdust, rice husk, peanut shell, Nut shell, forest waste, agri-waste etc.

Table of Contents

- How Does a Square Box-style Carbonizer Work, and How Is It Different from a Rotary Drum?

- In Terms of Footprint and Installation Flexibility, Which Furnace Has the Advantage?

- Which Design Better Guarantees Uniform Carbonization and Avoids Under-cooked Material?

- In the Long Term, Which Has Lower Maintenance Costs: Square or Rotary?

- Is My Raw Material (Lumpy, Powdery, Wet) Better Suited for a Square or Rotary Furnace?

- How Much Do the Two Options Differ in Cost for a Complete Production Line?

- How Do I Make the Smartest Choice Based on My Production and Site?

- FAQs

How Does a Square Box-style Carbonizer Work, and How Is It Different from a Rotary Drum?

A square furnace works by pushing a static bed of material through a heated box, which is fundamentally different from the tumbling action of a rotary drum. The core difference lies in how the material is moved and heated.

- Square Box-style Carbonizer: Imagine a long, insulated rectangular tunnel. The material is laid out on a conveyor system inside this tunnel—often a multi-layer mesh belt, a hydraulic pusher plate system, or screw augers. The material sits in a relatively still, flat bed as it is pushed from the cool inlet to the hot outlet. Heat is applied from heating plates located above and below the material bed. It’s a static heating process.

- Rotary Drum Carbonizer: This is a dynamic process. The cylindrical drum rotates, causing the material inside to constantly tumble and mix. This action, called “cascading,” ensures every particle is continuously exposed to the hot inner surface of the drum.

The veteran I spoke with called the material transport system in a square furnace its “Achilles’ heel.” This internal mechanism operates in a brutal environment of over 600°C, with no oxygen but plenty of corrosive gases. Metal belts stretch and jam, pusher plates warp in the heat, and augers wear down. The rotary drum’s drive system, in contrast, is located entirely outside the furnace, making it far more reliable and easier to maintain.

In Terms of Footprint and Installation Flexibility, Which Furnace Has the Advantage?

The square box-style furnace generally has a smaller footprint for the same production capacity. This is one of its primary marketing advantages and it is true. Because it can be designed with multiple layers of conveyors stacked vertically inside the insulated box, it can achieve a high throughput in a more compact, rectangular space.

- Square Furnace: Its boxy shape is easier to fit into existing buildings and alongside other rectangular equipment. The installation is often simpler as it doesn’t require the large, heavy-duty support rollers and massive ring gear that a rotary drum needs.

- Rotary Drum Furnace: A rotary drum is long and cylindrical. It requires a significant amount of linear space. It also needs a robust, precisely aligned foundation to support the heavy rotating drum and its drive mechanism.

However, the veteran warned me not to let footprint be the only deciding factor. “A small furnace that is always broken down takes up less space, but it also makes zero profit,” he said. While the Square Carbonization Furnace wins on footprint, this advantage can be quickly overshadowed by operational challenges if it’s not the right fit for your material.

Which Design Better Guarantees Uniform Carbonization and Avoids Under-cooked Material?

The rotary drum design provides vastly superior carbonization uniformity due to its continuous tumbling action. This is the most critical performance difference between the two types and it directly impacts your product quality and yield.

In a Box-type Carbonization Furnace, the material lies in a static bed. Heat has to travel from the outer heating plates down into the center of the bed. This creates an unavoidable problem:

- Uneven Heating: The material near the top and bottom gets cooked perfectly, but the material in the center of the bed doesn’t get enough heat and remains “under-cooked” or “raw.” We call this the phenomenon. To cook the center, you have to increase the temperature or time, which then turns the outer layers into ash, killing your yield.

- Cold Corners: The four corners of the square chamber are classic “cold spots” where material passes through almost untouched.

The Rotary Drum Carbonizer solves this problem naturally. The tumbling motion ensures every single particle is mixed and heated evenly. The result is a highly consistent final product with a much lower rate of under-cooked material, leading to a higher overall yield of high-quality charcoal. This is a fundamental advantage that no square furnace design can truly overcome.

In the Long Term, Which Has Lower Maintenance Costs: Square or Rotary?

A well-built rotary drum furnace has significantly lower long-term maintenance costs because its critical components are external and easily accessible. The claim that a square furnace is “low maintenance” because it has no rotating parts is a dangerous oversimplification.

- Square Furnace Maintenance: The nightmare begins when the internal conveyor system fails. This mechanism is inside a sealed, high-temperature box. To fix it, you have to shut down the furnace, wait one or two days for it to cool, and then send a technician to perform “keyhole surgery” through a small access hatch. It is difficult, dangerous, and results in days of lost production.

- Rotary Drum Maintenance: The drive system (motor, gearbox) and support rollers are all outside the furnace. They are easy to inspect, lubricate, and replace if needed. We call this “open-access maintenance.” The main wear parts are the seals, which are designed for regular replacement.

The veteran put it bluntly: “The square furnace has no small problems. It only has catastrophic ones.” The routine maintenance of a rotary drum is far less costly than the emergency “major surgery” required by a square furnace.

Is My Raw Material (Lumpy, Powdery, Wet) Better Suited for a Square or Rotary Furnace?

The rotary drum is far more versatile and forgiving with different types of raw materials. The square furnace is extremely “picky” about what you feed it.

Because it uses a static bed, the Box-type Carbonization Furnace struggles with many common types of biomass.

- It Hates Fluffy & Irregular Materials: Low-density materials like rice husks, chopped straw, or sawdust do not form a uniform bed. They can create “bridges” or “voids” inside the furnace. Hot gas will rush through these voids, bypassing the material entirely and leading to large patches of uncooked feedstock.

- It Loves “Standardized Parts”: The square furnace works best with uniform, dense materials that flow easily, such as biomass briquettes or pellets.

The Rotary Drum Carbonizer, with its tumbling action, can handle a much wider range of material shapes, sizes, and densities. It actively mixes the material, breaking up clumps and ensuring that even fluffy or irregular feedstocks are processed effectively. If your business relies on processing diverse agricultural or forestry waste, the rotary drum is the safer and more reliable choice.

| Feedstock Type | Square Furnace Suitability | Rotary Drum Suitability | Why? |

|---|---|---|---|

| Uniform Pellets/Briquettes | Good | Excellent | Square furnace can handle this, but rotary is still more uniform. |

| Wood Chips / Lumps | Poor | Excellent | Tumbling action is needed to heat large pieces evenly. |

| Sawdust / Powders | Very Poor | Good | Square furnace will have “voids”; rotary drum mixes it well. |

| High Moisture Material | Poor | Fair | Rotary’s tumbling helps release steam, but a pre-dryer is always recommended for both. |

How Much Do the Two Options Differ in Cost for a Complete Production Line?

The initial investment for a square furnace system might be slightly lower, but the total lifecycle cost is often higher due to lower efficiency and higher rates of rejected product. When you compare prices, you must look at the entire carbonization equipment production line plan.

A Square Carbonization Furnace might have a lower initial price tag because its construction seems simpler. However, the true cost of ownership must include the value of lost production.

Let’s assume a conservative reject rate of 15% for a square furnace due to uneven carbonization. This means for every 100 tons of raw material you buy and process, 15 tons of the output is unusable and needs to be re-processed or thrown away. You have paid for the raw material, the energy to heat it, and the labor to handle it, all for nothing. Over a year, this hidden cost of inefficiency can easily exceed the initial price difference between the two systems. A high-quality rotary drum, with its typical reject rate of less than 5%, provides a much faster and more reliable return on investment.

How Do I Make the Smartest Choice Based on My Production and Site?

The smartest choice comes from honestly assessing your feedstock and prioritizing long-term reliability over a small upfront saving.

- If Your Raw Material is 100% Uniform Pellets or Briquettes AND Your Factory Space is Extremely Limited: A high-quality, well-engineered Square Box-style Furnace from a reputable manufacturer could be a viable option. You must insist on seeing the internal drive system and understanding its materials and maintenance plan.

- If You Process Diverse or Irregular Materials (wood chips, agricultural waste, etc.): The Rotary Drum Carbonizer is the clear and undisputed winner. Its versatility, superior heat transfer, and proven reliability make it the industry standard for a reason.

- Prioritize Reliability: Ask yourself: Can my business afford several days of downtime for a major internal repair? For most producers, the answer is no. The external maintenance and proven robustness of the rotary drum offer greater peace of mind and more predictable production.

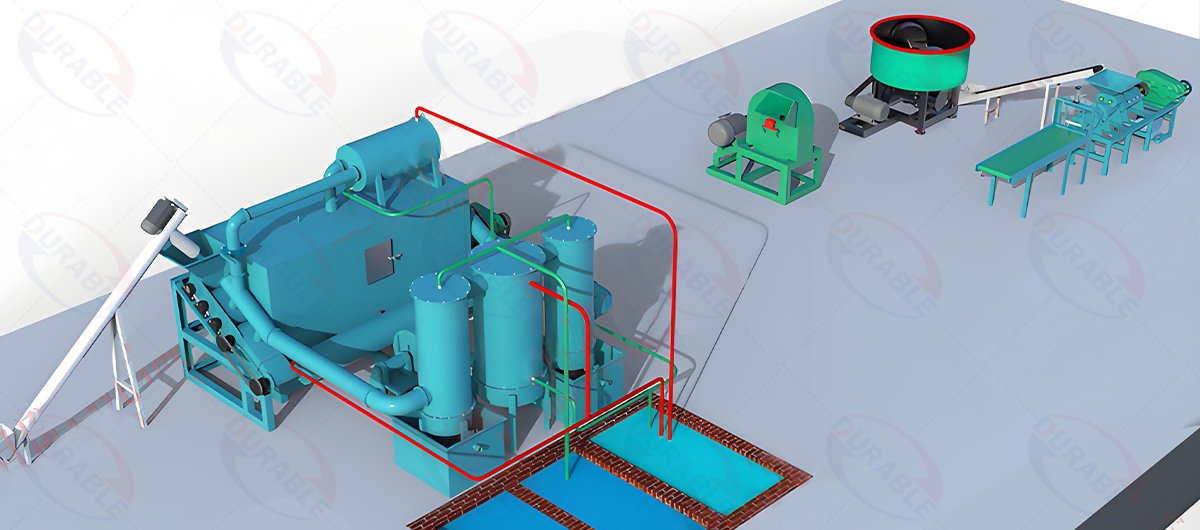

At Durable, we have the expertise to build both types of systems. However, based on decades of experience and feedback from operators in the field, we almost always recommend the Horizontal Continuous Carbonization Furnace (Rotary Drum) for its superior performance and long-term value. We believe in providing solutions that work reliably for years, not just ones that look good on a quote.

FAQs

Q1: Is a square furnace really “smokeless”?

A: Like a rotary furnace, a square furnace can be “smokeless” if it has a complete and functional system to capture and burn the syngas. The technology for gas treatment is the same for both. The reliability of the furnace’s seals is the key factor in preventing leaks.

Q2: What is the main cause of failure in a square furnace?

A: The most common and catastrophic failure is the breakdown of the internal material transport system (mesh belt, pusher plate, or screw). This is due to the extreme heat and corrosive environment inside the furnace.

Q3:Is it easier to control the temperature in a square furnace?

A: No, it is much harder. With a static bed of material, it’s very difficult to get heat to the center without overheating the outer layers. A rotary drum’s mixing action makes temperature control much easier and the heat distribution far more even.

Q4:Can a square furnace handle materials with higher moisture?

A: No. In fact, it is often worse. Steam released from wet material can get trapped within the static bed, creating wet pockets and preventing proper carbonization. A pre-dryer is absolutely essential for both furnace types, but especially for a square one.

Q5: Why do some manufacturers still promote square furnaces?

A: They are often promoted based on their smaller footprint and the misleading claim of “lower maintenance” due to having no large rotating parts. For customers with very specific, uniform feedstock and severe space constraints, they can appear attractive. However, these advantages often come at the cost of efficiency and reliability.

Durable Machinery

Durable Machinery