The Difference Between Biochar and Charcoal: A Complete Guide

At Durable, we have been building Charcoal Production Lines and biomass equipment for years. One of the most common points of confusion we see is the difference between biochar vs charcoal. They look identical, but they are fundamentally different products created for completely different markets. Understanding this difference is the first step to a profitable business. This guide will explain why choosing the right name—and the right production process—is critical to your success.

Table of Contents

- What is the fundamental difference in use between biochar and charcoal?

- How does the production process differ for these two products?

- Is the fuel market (charcoal) or soil market (biochar) better?

- Can you sell one batch of carbon as both biochar and charcoal?

- How to Choose the Right Equipment?

- Conclusion

What is the fundamental difference in use between biochar and charcoal?

The single most important difference between biochar and charcoal is their purpose. You must first ask, “What is the final job of this piece of carbon?”

- Charcoal’s job is to be destroyed. It is designed to be an efficient fuel. Its value comes from its ability to burn and release stored energy. It is an energy carrier. Its primary market is for cooking, grilling (BBQ), and industrial heating.

- Biochar’s job is to last for centuries. It is designed to be a permanent soil amendment. Its value comes from its physical structure (high porosity) and chemical properties (ability to hold water and nutrients). It is a functional carrier. Its primary market is agriculture, horticulture, and environmental remediation.

Thinking of biochar as “agricultural charcoal” is a costly mistake. You are not selling a fuel; you are selling a high-performance soil-improvement tool. This fundamental difference in purpose dictates every other decision in your production process.

How does the production process differ for these two products?

Both products are made through pyrolysis, which is heating biomass in a low-oxygen environment. However, the specific process parameters, especially temperature, are completely different. Getting the temperature wrong will result in a product that fails in its intended market.

| Feature | Biochar Production | Charcoal Production | Why It Matters for You |

|---|---|---|---|

| Temperature | Lower (350°C – 600°C) | Higher (>600°C) | This is the most critical factor. Lower temps preserve the structures that biochar needs, while higher temps create the pure carbon that charcoal needs. |

| Primary Goal | Preserve porous structure and surface chemistry. | Maximize fixed carbon content and energy density. | You are either trying to create a “sponge” for soil (biochar) or a “battery” for heat (charcoal). |

| Raw Material | Diverse. Driven by desired function (e.g., rice husks for high porosity). | Dense hardwoods are preferred for high-quality lump charcoal that burns long. | Your raw material choice should be based on the final product’s performance requirements. |

Using a high temperature (over 700°C) to make biochar will destroy its porous structure and make it useless for agriculture. It becomes like adding tiny glass beads to the soil. Conversely, using a low temperature to make charcoal will leave too many volatiles, resulting in a smoky, low-quality fuel that no one wants to buy.

Is the fuel market (charcoal) or soil market (biochar) better?

The economic models for charcoal and biochar are worlds apart. You are entering two very different industries.

The Charcoal Market

This is a traditional commodity market.

- Value Proposition: You are selling heat. Price is determined by weight, heat value (calorific value), and burn time.

- Competition: The market for BBQ and industrial charcoal is well-established and highly competitive.

- Profit Margin: Margins are typically lower. Success depends on high-volume production and efficient logistics.

The Biochar Market

This is a modern value-added specialty market.

- Value Proposition: You are selling agricultural performance and environmental benefits. Price is determined by certified metrics like porosity, pH, and its ability to sequester carbon.

- Competition: This is a growing market driven by sustainable agriculture and the carbon credit economy.

- Profit Margin: Margins can be significantly higher, especially for certified, high-quality biochar. Success depends on quality control, lab testing, and marketing the product’s benefits.

The charcoal market is stable but crowded. The biochar market has enormous growth potential but requires a more scientific and marketing-focused approach.

Can you sell one batch of carbon as both biochar and charcoal?

The simple answer is no. This is a common but flawed idea. The production processes are optimized for opposite outcomes.

Think of it like this:

- A product made at 450°C will have the porous structure and chemical activity to be excellent biochar. However, it will contain too many volatiles to be good charcoal. It will be smoky and have a lower heat value.

- A product made at 700°C will have the high fixed carbon content to be excellent charcoal. It will burn hot and clean. However, the high temperature will have destroyed the delicate pore structure, making it an inert and ineffective soil amendment.

Trying to create a “one-size-fits-all” product will result in a batch of carbon that is mediocre at both jobs and will fail to satisfy customers in either market. You must commit to one production path to create a high-quality, sellable product.

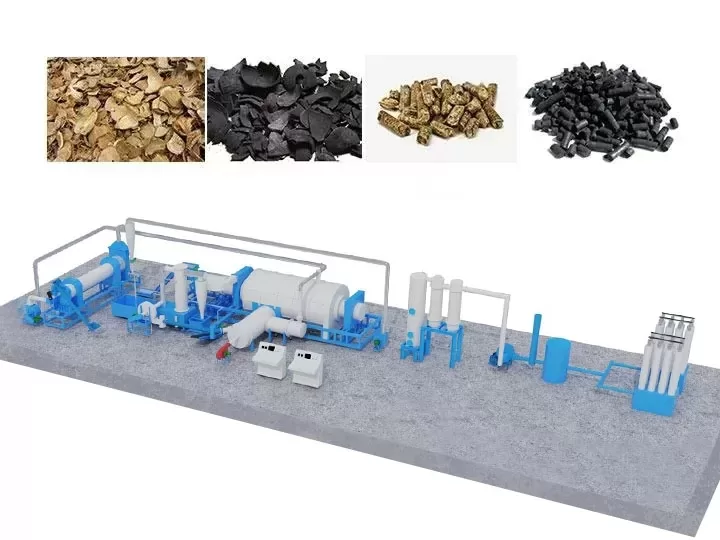

How to Choose the Right Equipment?

When you approach an equipment manufacturer like Durable, the most important thing you can do is be clear about your intended final product. Do not just say you want a “carbonization machine.”

- If you want to make biochar: Tell your supplier, “I need a rotary drum biomass carbonization furnace optimized for precise temperature control in the 400-600°C range. I need to be able to control the heating rate and residence time to maximize porosity.”

- If you want to make charcoal: Tell your supplier, “I need a charcoal machine designed for high-throughput and high temperatures. My goal is to maximize fixed carbon content and produce a dense, high-energy fuel.”

A professional supplier will understand these different requirements. A biochar kiln may have more sophisticated controls and monitoring, while a charcoal machine might be built for more robust, continuous high-temperature operation. Your initial conversation with the supplier sets the entire technical direction for your project.

Conclusion

The line between biochar vs charcoal is not blurry; it is a sharp divide defined by purpose. Your choice determines your production process, your equipment needs, your target market, and your ultimate profitability.

- Charcoal is a fuel. It is a high-volume commodity sold based on its energy content.

- Biochar is a soil tool. It is a high-value specialty product sold based on its agricultural performance and environmental benefits.

You must decide which business you want to be in before you invest a single dollar. Choose your path, commit to the correct process, and produce a high-quality product that meets the specific demands of your chosen market.

Durable Machinery

Durable Machinery