What Is a Ball Mill?

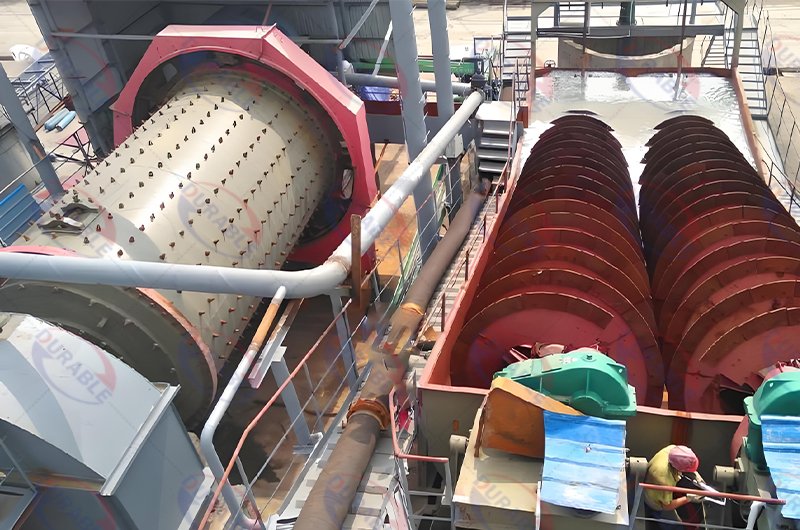

In our many years in the heavy machinery industry, we at Durable Machine have seen many technologies change. But the Ball Mill remains a true workhorse. It is a key piece of grinding equipment. You will find it in almost every serious mineral processing and cement production line. If you need to turn hard, coarse material into a fine powder, the ball mill is your essential tool. It is the heart of the grinding circuit.

Table of Contents

- What is a ball mill’s key role in your production line?

- How does a ball mill grind hard ore into powder?

- Why is a ball mill vital for mining and cement?

- Wet vs. Dry ball mill: Which is for you?

- Overflow vs. Grate ball mill: What’s the difference?

- What factors affect ball mill efficiency?

- How to choose the right ball mill model?

- Common Questions Answered

- Summary and Recommendations

What is a ball mill’s key role in your production line?

A ball mill is a type of grinder that reduces the size of materials. Its main job is to grind and blend materials for use in mineral processing, paints, pyrotechnics, ceramics, and cement production. Think of it as the final step in breaking down rock. First, crushers break large rocks into smaller pieces. Then, the ball mill takes those crushed pieces. It grinds them into a fine or even ultrafine powder. This process is called comminution.

The key role of a mining ball mill is liberation. This means it grinds the ore until the valuable mineral particles, like gold or copper, are freed from the waste rock. Once liberated, these valuable minerals can be separated using other methods. In a cement plant, a cement ball mill grinds the hard, fused material called “clinker” into the fine powder we know as cement. The fineness of this powder determines the strength and quality of the final concrete product. So, the ball mill is not just a grinder. It is a critical machine that makes the next stage of your process possible and efficient. Without it, you cannot unlock the value from your raw materials.

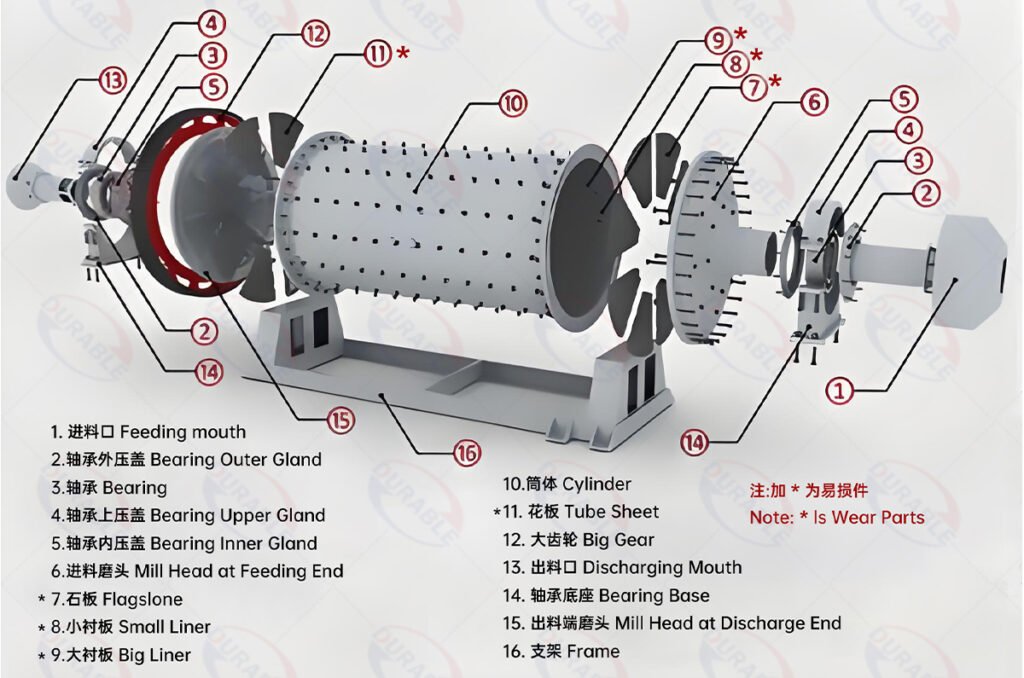

A Ball Mill’s Core Components

Understanding the parts of a ball mill helps you understand how it works and what to look for during maintenance. Each part has a specific and important job.

- Cylindrical Shell: This is the main body of the mill. We make it from thick, high-strength steel plates to handle the heavy load and intense forces inside.

- Grinding Media: These are the steel balls that do the actual grinding. We select their size and material, like high-chrome forged steel, very carefully. The choice depends on the hardness of your ore and the final particle size you need.

- Liners: These are wear plates bolted to the inside of the shell. They have two jobs. First, they protect the shell from being worn down by the balls and material. Second, their shape helps lift the balls correctly for efficient grinding.

- Inlet and Outlet Trunnions: The material is fed into the mill through a hollow shaft, or trunnion, at one end. The ground material exits through a trunnion at the other end.

- Drive System: This is the powerhouse that rotates the mill. It includes a large electric motor, a gearbox to reduce speed, and a pinion gear that turns a massive girth gear mounted on the shell.

- Bearings: These are huge, robust bearings that support the entire weight of the rotating mill, the steel balls, and the material inside. They are critical for smooth operation.

How does a ball mill grind hard ore into powder?

A ball mill grinds ore through impact and attrition. The process is simple in concept but very powerful in action. The mill is a large rotating cylinder. It is filled with the material you want to grind and the grinding media, which are steel balls. As the cylinder rotates, the magic begins.

The rotation lifts the steel balls up the side of the shell. When they reach a certain height, they fall back down. This creates two grinding actions. At lower speeds, the balls cascade over each other. This creates a rubbing and abrasion action, like using sandpaper. This is called attrition, and it’s great for making very fine particles. At higher speeds, the balls are thrown across the mill. They crash down onto the material at the bottom. This is called impact, and it’s excellent for breaking down coarser particles. A well-run ball mill balances these two forces. This balance gives you the most efficient grinding for your specific material and needs. Material is fed into one end of the mill. It stays inside for a set amount of time. Then, it exits the other end as a fine powder or slurry.

Why is a ball mill vital for mining and cement?

In mineral processing and cement industries, the ball mill is not optional; it is essential. This is because these industries depend on changing the physical properties of raw materials. The ball mill is the primary tool to achieve the required particle size for further processing. Its role is so central that the entire plant’s efficiency often depends on the performance of the grinding circuit.

For our mining clients who handle gold, copper, or iron ore, the goal is to liberate valuable minerals. The ball mill grinds the ore rock, which often comes from our crushing equipment, to a specific size. This size frees the tiny mineral specks from the waste rock. Without this step, separation processes like flotation or leaching would not work. For cement producers, the cement ball mill is the final stage of production. It grinds hard clinker into a fine powder. The particle size distribution of this powder directly affects the final cement quality, including its strength and setting time. In short, the ball mill transforms low-value raw material into a high-value, process-ready product. This makes it one of the most important investments in any mineral processing plant.

Wet vs. Dry ball mill: Which is for you?

Choosing between wet grinding and dry grinding depends entirely on your product and process needs. Both methods use a ball mill, but the presence of water changes everything, from efficiency to material handling. We can help you decide which method is the best fit for your operation.

Wet grinding is the most common method in the mineral processing industry. In this process, water is added to the mill along with the material. This creates a slurry. Wet grinding is generally more efficient than dry grinding. The water helps to move the material, reduces dust problems, and cools the mill. The resulting slurry is also easier to pump and transport to the next stage, such as a flotation circuit. If your final product can be wet, this is usually the better choice.

Dry grinding is used when the final product must be dry. The most common example is the production of cement. Water cannot be present when grinding clinker. Dry grinding is also used for making powders for paints or other chemicals. This method requires a more complex system to handle the fine dust created during the process. It often uses more energy, but for certain applications, it is the only option.

| Feature | Wet Grinding | Dry Grinding | How It Affects You |

|---|---|---|---|

| Efficiency | Generally higher energy efficiency | Lower energy efficiency | Wet grinding can lower your electricity costs. |

| Dust Control | Excellent, as water suppresses dust | Requires complex dust collection systems | Wet grinding improves workplace safety and environment. |

| Material Handling | Slurry is easy to pump and transport | Powder is harder to handle and can be explosive | Wet grinding simplifies your plant layout. |

| Common Application | Most mineral processing (gold, copper, iron ore) | Cement, paints, some chemical powders | Your final product determines the best method. |

Overflow vs. Grate ball mill: What’s the difference?

The main difference between an overflow and a grate ball mill is how the material leaves the mill. This design choice affects the particle size of your product and the overall efficiency of the grinding circuit. As a manufacturer, we produce both types to meet the specific needs of your project.

An overflow ball mill has a simpler design. The ground material, mixed with water as a slurry, simply overflows out of the discharge end of the mill. The outlet is at a slightly lower level than the inlet. This type of mill is typically used for finer grinding applications. It allows the material to stay in the mill for a longer time, ensuring it is ground to a very fine size.

A grate ball mill has a grate, which is like a screen, at the discharge end. This grate has slots that only allow material of a certain size to pass through. Lifters behind the grate then lift the material and discharge it from the mill. This design forces the material out of the mill more quickly. It is good for preventing over-grinding of soft minerals. It is often used in the first stage of a two-stage grinding process where you need to produce a coarser product.

What factors affect ball mill efficiency?

Several key factors determine your ball mill’s grinding efficiency and long-term operating costs. Getting these factors right is crucial for a profitable operation. When we design a ball mill for you, we consider each of these points carefully to create the most effective solution.

The most important factor is the mill speed. The speed at which the mill rotates affects how the steel balls move inside. If the speed is too slow, the balls will just roll down, resulting in poor grinding. If it’s too fast, the balls will stick to the side of the mill due to centrifugal force and won’t grind at all. The optimal speed, usually around 75% of the critical speed, balances impact and attrition for maximum efficiency.

Other critical factors include the grinding media charge and size. The mill should be filled to about 30-45% of its volume with steel balls. The size of the balls matters too. Larger balls are better for breaking down coarser feed material, while smaller balls are better for producing a finer final product. The material of the liners inside the mill also plays a big role. Their shape is designed to lift the balls properly. Finally, the hardness of the ore itself, measured by something called the Bond Work Index, dictates how much energy is needed for grinding. Optimizing these factors together is the key to an efficient milling process.

How to choose the right ball mill model?

Choosing the right ball mill model requires a close look at your project’s core parameters. It is not a one-size-fits-all decision. As your equipment partner, we guide you through this process to ensure the grinding equipment you buy is a perfect match for your needs.

First, you must know your material characteristics. How hard is your ore? How abrasive is it? What is the size of the material you will be feeding into the mill? These answers help determine the power required and the type of liners and grinding media you will need. Second, define your required product fineness. This is the most important question. The particle size you need for your downstream process, like in our flotation machines, will determine the type and size of the mill.

Third, what is your required capacity? You need to know how many tons per hour you need to process. This directly determines the diameter and length of the ball mill. Fourth, you must have already decided between wet or dry grinding, as this changes the mill’s design. Finally, we look at the entire circuit. A ball mill does not work alone. It works with pumps and classifiers, like hydrocyclones, in a closed loop. We ensure the mill we design integrates perfectly into your complete mineral processing plant. By analyzing these core parameters together, we can provide you with a customized ball mill that is both efficient and cost-effective.

Common Questions Answered

Q1: What is grinding media in a ball mill?

A: Grinding media is the material inside the mill that does the actual grinding. In a ball mill, the media is typically hardened steel balls. The size, shape, and material of the media are chosen based on the specific grinding application.

Q2: What is the difference between a ball mill and a rod mill?

A: A rod mill is very similar to a ball mill, but it uses long steel rods as the grinding media instead of balls. Rod mills are generally used for coarser grinding and produce a product with fewer ultra-fine particles compared to a ball mill.

Q3: How much does a mining ball mill cost?

A: The cost of a mining ball mill varies greatly. It depends on its size (diameter and length), the power of the motor, the type of liners, and whether it is a new or used machine. For an accurate quote, you must provide your specific project requirements.

Q4: Can a ball mill handle very hard ores?

A: Yes, ball mills are designed to handle very hard and abrasive ores. The key is to select the correct specifications, including a powerful motor, durable high-manganese or chrome-moly steel liners, and high-chrome forged steel balls as grinding media.

Summary and Recommendations

The Ball Mill is a fundamental piece of grinding equipment for any serious mining or industrial operation. It uses the simple but powerful forces of impact and attrition to reduce hard materials to a fine powder. Understanding the key differences between wet and dry grinding, and between overflow and grate discharge types, is the first step in selecting the right machine.

To get the most out of your investment, you must choose a model based on your specific needs. Consider your material type, desired output size, and required capacity. As an experienced manufacturer, we are here to help you navigate these choices. We can design and build a ball mill that perfectly fits your production line, helping you achieve maximum efficiency and profitability.

Durable Machinery

Durable Machinery