Planetary Concrete Mixer

Discharging volume(L):

330-3000

Charging volume(L):

500-4500

As an expert in heavy equipment and construction material production, I understand concrete mixing technology deeply. In our product line, a planetary concrete mixer is a highly efficient machine. We design it for making high-quality, very uniform, special concrete. It differs from common twin-shaft mixers and vertical shaft forced mixers. Its unique mixing method gives it great advantages in certain uses.

A planetary concrete mixer gets its name from how its mixing parts move. They move like planets orbit and spin. It is a vertical shaft forced mixer. Its main feature is that the mixing paddles orbit the center shaft of the mixing drum. At the same time, they also spin fast around their own axes. This creates a complex and thorough mixing path. It ensures materials become extremely uniform in a short time.

Table of Contents

- What are the working principles and core advantages of a planetary concrete mixer?

- What Key Components Make Up a Planetary Mixer?

- Which Special Concrete Types Are Suitable for a Planetary Concrete Mixer?

- How Do You Choose the Right Planetary Mixer Model Based on Production Needs?

- What Are the Costs and Expected Returns of Investing in a Planetary Concrete Mixer?

- What Are the Daily Maintenance Points for a Planetary Concrete Mixer?

- FAQs

What are the working principles and core advantages of a planetary concrete mixer?

A planetary concrete mixer aims to produce very uniform concrete. It prevents materials from separating. Its working method is unique. This leads to clear mixer advantages over other types. It is especially good for mixes that need great precision.

This mixer is designed for tough mixing jobs. It ensures every particle is fully mixed. This helps create top-quality concrete.

Core Functions and Benefits

The main goal of a planetary mixer is to make concrete that is highly uniform. It also stops segregation. Its working principle is as follows:

- Vertical Mixing Shaft Design: The main mixer has a vertical shaft design. The mixer parts are in the middle of a round mixing drum.

- Planetary Movement:

- Mixing arms, also called the planetary frame, move around the center axis of the mixing drum. This is like a planet orbiting the sun.

- Each mixing arm has several mixing paddles or scrapers. These paddles spin fast around their own axis. This happens while they orbit the center.

- Multiple Mixing Actions: This combined movement of orbiting and spinning means the paddles reach every part of the drum. There are no dead spots in the mixing area. Materials in the drum flow, shear, knead, and spread. Particles hit each other and rub. This makes the materials mix evenly at a very small level.

- Wall Scraper Device: Scrapers are usually on the ends of the mixing arms. They regularly scrape material from the drum walls. This stops sticking. It brings the material back into the main mixing area.

- Bottom Discharge: The mixed material exits through a discharge gate at the bottom of the drum. This gate is usually controlled by hydraulics or air pressure. This allows for quick and complete emptying.

| Core Advantage | How It Works | Your Direct Benefit |

|---|---|---|

| Superior Uniformity | Complex planetary motion, no dead zones | High-quality concrete, consistent performance |

| Effective Dispersion | High shear and kneading forces | Better material bonding, stronger concrete |

| Anti-Segregation | Handles fibers/fine powders well | Consistent product quality, less waste |

| Versatile Material Use | Mixes dry-hard to high-viscosity materials | Wide range of concrete types, more product options |

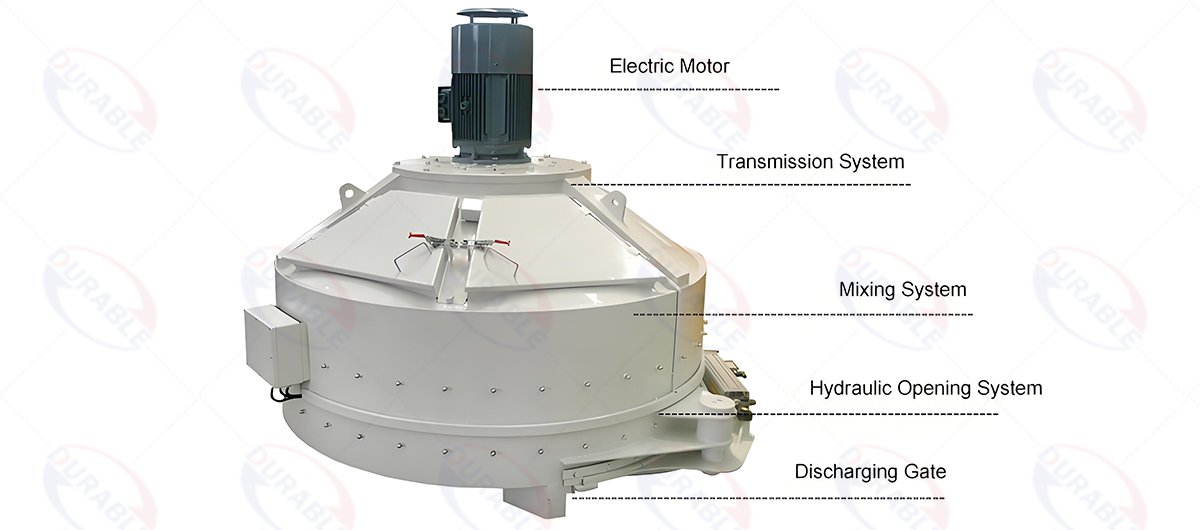

What Key Components Make Up a Planetary Mixer?

A planetary mixer is built with several key parts. Each part works together to achieve its high-performance mixing. Knowing these parts helps you understand the mixer’s design. It also shows why it provides such excellent mixing uniformity.

The design of each part focuses on durability and efficiency. This ensures the mixer lasts long. It also helps it perform well under demanding conditions. This makes it a great choice for high-performance concrete mixing.

Mixer Structure and Parts

Our planetary concrete mixers have excellent mixing uniformity and quality. This comes from their unique design and strong parts.

Compound Planetary Motion: This is the core advantage. The mixing paddles cover the entire mixing area. They leave no dead spots. This achieves uniform mixing down to the very small level. It is especially good for concrete that needs exact color, strength, and density.

- High Shear and Kneading Force: The paddles apply strong shear, squeezing, and kneading forces to the material. This happens as they spin and orbit. This effectively breaks up cement clumps. It helps cement, aggregates, water, and additives mix fully. This makes the concrete perform at its best.

- Prevents Segregation: This mixer effectively stops material from separating. This is true for concrete with fibers, color powders, very fine powders, or special aggregates. It ensures the finished product is consistent.

- Wide Material Adaptability and Versatility:

◦ Low Slump and High Viscosity Materials: It mixes dry-hard, semi-dry, high-viscosity, and low-slump concrete very well. This is useful for making precast parts like pipes, poles, road slabs, and blocks.

◦ Special Concrete: It is ideal for making specialty concrete mixer types. This includes self-compacting concrete (SCC), high-strength concrete, fiber concrete, colored concrete, permeable concrete, lightweight aggregate concrete, and steel fiber concrete. It also mixes refractory materials, ceramics, glass, and mortar.

◦ Large Aggregate Sizes: It can effectively mix concrete that has large aggregate sizes. - Robust and Low Maintenance:

◦ High Wear-Resistant Materials: Key wear parts like mixing paddles, liners, and scrapers are made from high-chrome cast iron, high-manganese steel, or composite wear-resistant alloys. They are specially heat-treated. This gives them a very long life. It also makes them resistant to impact.

◦ Heavy-Duty Drive System: It uses a special planetary gearbox. This provides smooth power, high torque, and low noise. It ensures stable operation over long periods, even under heavy loads.

◦ Advanced Shaft End Seal: It uses multiple types of shaft end seals. These include floating seals, mechanical seals, and oil seals. They stop slurry from leaking effectively. They protect the gearbox. They also reduce maintenance needs and costs.

◦ Easy Maintenance: The mixer has wide inspection doors. This makes internal cleaning and changing wear parts easy. - High Efficiency and Compact Design:

◦ Fast Mixing Cycle: Its unique mixing method makes materials uniform quickly. This shortens mixing time. It increases production efficiency.

◦ Small Footprint: Its vertical design means it takes up less space. This is true compared to horizontal mixers of the same capacity. This makes it easier to set up in limited areas. - Smart Control System: It can connect smoothly with a concrete batching plant control system. This allows full automatic control. It precisely controls mixing time and speed. It records data and diagnoses faults. It is easy to use.

| Component | Function | Your Benefit |

|---|---|---|

| Planetary Gearbox | Powers complex paddle motion, high torque | Reliable mixing, long operational life |

| Mixing Paddles/Arms | Unique orbit and spin, intense mixing | Superior uniformity, no dead zones |

| Wear-Resistant Liners | Protects drum, extended lifespan | Reduced maintenance, consistent mixing quality |

| Shaft End Seals | Prevents leakage, protects gearbox | Lower maintenance costs, cleaner operation |

| Discharge Gate | Quick, thorough emptying | Efficient material transfer |

Which Special Concrete Types Are Suitable for a Planetary Concrete Mixer?

A planetary concrete mixer is especially good for handling specialty concrete mixer types. These are mixes that need very high quality and specific properties. Its unique mixing action makes it ideal for these demanding materials. It ensures excellent mixing uniformity for even the most complex mixes.

This mixer can produce concrete for highly specific applications. It is perfect when standard mixers cannot achieve the required quality.

Handling Demanding Mixes with Ease

A planetary concrete mixer is the ideal choice for these B2B customer groups that demand high concrete quality:

- Precast Concrete Component Producers: They make various precast parts. These include concrete pipes, poles, railway sleepers, kerbstones, hollow slabs, colored bricks, blocks, and external building panels. These products need extremely high strength, density, and consistent appearance. The mixer ensures every batch meets these strict standards. It provides the necessary precision for perfect finishes.

- Specialty Concrete Producers: They make self-compacting concrete (SCC), high-strength concrete, colored concrete, fiber-reinforced concrete, permeable concrete, lightweight aggregate concrete, and steel fiber concrete. The mixer’s strong shear and kneading actions break up additives evenly. This creates a homogeneous mix. This is crucial for these advanced concrete types.

- Dry Mix Mortar Production Lines: They produce various dry mix mortars. These include plastering mortar, adhesive mortar, and flooring mortar. These materials need uniform and stable components. The mixer ensures all parts, from sand to fine additives, are perfectly blended.

- Refractory Material Producers: They mix various refractory materials. These include unshaped refractory materials and castables. They need high uniformity to ensure their heat-resistant properties. The mixer can handle the high density and abrasive nature of these materials.

- Glass and Ceramics Industries: They mix glass melts and ceramic slurries. The mixer’s precision ensures consistent material properties for high-quality final products.

- Engineering Laboratories and R&D Institutions: They use the mixer for developing new concrete formulas and material testing. It ensures the accuracy of small-batch test results. This is vital for research and development.

- Mining and Metallurgy: They use it to produce specific-purpose solidifiers, slag treatment agents, or other special mixtures. The mixer ensures these complex blends are consistent and effective.

How Do You Choose the Right Planetary Mixer Model Based on Production Needs?

Choosing the right planetary mixer model is very important. It means matching its capacity and features to your specific production needs. This ensures efficient and cost-effective high-performance concrete mixing. The correct choice helps you meet your quality goals without waste.

Picking the right mixer involves looking at many details. This helps you get the most out of your investment. It ensures smooth production.

Technical Parameters

| Model | PCM330 | PCM500 | PCM750 | PCM1000 | PCM1500 | PCM2000 | PCM2500 | PCM3000 |

| Discharging Volume (L) | 330 | 500 | 750 | 1000 | 1500 | 2000 | 3000 | 3000 |

| Charging Volume (L) | 500 | 750 | 1125 | 1500 | 2250 | 3000 | 3750 | 4500 |

| Input Mass (kg) | 800 | 1200 | 1800 | 2400 | 3600 | 4800 | 6000 | 7200 |

| Mixing Power (kw) | 15 | 18.5 | 30 | 37 | 55 | 75 | 90 | 110 |

| Discharge Power (kw) | 2.2 | 2.2 | 2.2 | 3 | 3 | 4 | 4 | 4 |

| Lifting Power (kw) | 4 | 4 | 7.5 | 11 | 15 | 22 | — | — |

| Skipper Capacity (L) | 580 | 870 | 1300 | 1740 | 2610 | 3480 | — | — |

| Skipper Mass (kg) | 870 | 1305 | 1950 | 2610 | 3615 | 5220 | — | — |

| Skipper Speed (m/s) | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | — | — |

| Weight (kg) | 1700 | 2000 | 3500 | 6000 | 7000 | 8500 | 10500 | 11000 |

| Dimension (mm) | 1910 x 1590 x 1747 | 2220 x 2071 x 1880 | 2581 x 2336 x 2195 | 2891 x 2602 x 2217 | 3223 x 2902 x 2425 | 3625 x 3230x 2630 | 2893 x 3550 x 2695 | 3893 x 3550x 2975 |

Factors for Mixer Model Selection

When choosing a planetary mixer, consider these factors:

- Required Production Capacity:

◦ Hourly Output: How many cubic meters of mixed material do you need per hour? Our mixers range in capacity. They start from small lab models to large production units. Match this to your peak demand.

◦ Batch Size: What is the typical volume of one batch you need to mix? The mixer’s nominal capacity refers to the output per batch. - Material Type:

◦ Concrete Type: Are you making dry-hard concrete, self-compacting concrete, fiber concrete, or standard concrete? Different concrete types have different mixing needs. Planetary mixers excel at difficult mixes.

◦ Aggregate Size: While planetary mixers can handle large aggregates, ensure the chosen model’s design (e.g., paddle clearance) is suitable for your maximum aggregate size.

◦ Additive Type: If you use many fine powders or fibers, choose a mixer known for excellent dispersion. - Mixing Time Requirements: Some special concrete types need longer mixing times. Ensure the mixer can handle these cycles efficiently. Planetary mixers are known for faster uniform mixing.

- Footprint and Space Constraints: Planetary mixers have a vertical design. This means they take up less space than horizontal mixers of the same capacity. This makes them good for sites with limited area.

- Integration with Existing Plant: If you are adding the mixer to an existing concrete batching plant, ensure it can integrate easily. This includes material feeding and discharge systems.

- Budget: Balance the initial investment with the long-term benefits. These include superior concrete quality, reduced waste, and lower maintenance needs.

- Automation Needs: Do you need a fully automated system? Or is a manual control sufficient? Our mixers can integrate with full automation systems.

Our engineering team works with you closely. We understand your production goals. We help you select the exact planetary mixer model. We ensure it perfectly fits your needs.

What Are the Costs and Expected Returns of Investing in a Planetary Concrete Mixer?

Investing in a planetary concrete mixer involves certain costs. But it also offers significant returns. These returns go beyond the initial price. They include benefits like improved product quality. They also include reduced material waste and operational efficiency. Understanding these aspects helps you see the true value of your investment.

While the initial mixer price might be higher than standard mixers, the long-term gains can be substantial. This is especially true for producing high-performance concrete.

Analyzing Investment and Operational Value

Initial Investment (Mixer Price): The purchase price of a planetary concrete mixer depends on its capacity, features, and brand. It is generally higher than traditional twin-shaft mixers of similar capacity. This is due to its complex planetary gear system and robust wear parts. However, for specialized concrete, this higher initial cost is often justified by superior performance.

- Installation Costs: Planetary mixers usually have a vertical design. This can simplify installation in some settings. They might need specific foundations. These costs are generally moderate.

- Operational Costs:

◦ Energy Consumption: Planetary mixers are efficient. They achieve uniformity quickly. This can lead to shorter mixing cycles. This reduces overall energy use per cubic meter of concrete.

◦ Wear Parts Replacement: Components like mixing paddles and liners are subject to wear. But our mixers use high wear-resistant materials. This extends their life. This reduces the frequency and cost of replacements.

◦ Labor Costs: Automated controls and easy maintenance features can reduce the need for constant operator oversight. This saves on labor. - Maintenance Costs: Our mixers feature advanced shaft end seals and easy-access designs. This minimizes slurry leakage. It also simplifies cleaning and maintenance. This lowers overall mixer maintenance costs over the equipment’s lifespan.

- Return on Investment (ROI):

◦ Superior Product Quality: The primary return is the ability to produce high-performance concrete. This concrete has excellent mixing uniformity. This leads to stronger, more consistent, and higher-value finished products. This can increase your market share and pricing power.

◦ Reduced Material Waste: Precise mixing means less material is wasted due to poor quality. This is especially true for expensive specialty additives.

◦ Increased Production Efficiency: Faster mixing cycles mean higher throughput. This can help you meet tighter deadlines. It can also take on more projects.

◦ Lower Long-Term Costs: The durability and low maintenance needs lead to a longer service life. This reduces total ownership costs over time.

◦ Expanded Product Range: The ability to mix specialty concrete mixer types allows you to offer more products. This opens new markets and revenue streams.

What Are the Daily Maintenance Points for a Planetary Concrete Mixer?

Daily maintenance is crucial for your planetary concrete mixer. It ensures the mixer runs smoothly. It also extends its service life. This prevents unexpected breakdowns. It also helps maintain consistent mixing uniformity.

Regular checks and prompt actions keep your mixer in top working order. They also help secure your investment. Following these simple steps can save you time and money.

Essential Daily Care for Your Planetary Mixer

To keep your planetary concrete mixer running efficiently, follow these daily maintenance points:

Pre-Operation Check: Before starting, visually inspect the mixer. Look for any loose bolts, worn parts, or visible damage. Ensure all safety guards are in place. Check that the emergency stop button works correctly.

- Mixer Drum and Paddle Cleaning: This is the most critical step. Clean the mixer drum and paddles thoroughly after each shift. Dried concrete can harden and cause damage. Use the built-in cleaning system or manual scraping tools. Pay attention to the wall scrapers.

- Lubrication Check: Ensure all moving parts are properly lubricated. Check grease points for bearings and the planetary gearbox. Top up lubricants if needed, following the manufacturer’s schedule. This prevents excess wear.

- Shaft End Seal Inspection: Regularly inspect the shaft end seals. Look for any signs of slurry leakage. If you see leaks, address them immediately. Leaks can damage the gearbox. This is a key part of mixer maintenance.

- Wear Parts Assessment: Check the condition of mixing paddles, liners, and scrapers. Look for excessive wear. Plan for replacement before they significantly impact mixing uniformity. These are made from high-wear-resistant materials, but they still need monitoring.

- Discharge Gate Operation: Test the discharge gate. Ensure it opens and closes smoothly. Check for any material buildup that might obstruct it.

- Electrical and Control System: Check the control panel for any error messages. Ensure all indicators and lights work. Inspect electrical cables for wear or damage.

- Gearbox Noise: Listen for any unusual noises from the planetary gearbox. Strange sounds might indicate an issue needing professional attention.

- General Cleanliness: Keep the area around the mixer clean. Remove any spilled concrete or debris. This creates a safer work environment.

FAQs

Q 1: What makes a planetary mixer better for dry-hard concrete?

A: A planetary mixer is better for dry-hard concrete because its strong kneading action and multiple mixing paths ensure thorough and uniform blending of low-slump mixes. This prevents clumping and ensures consistent strength.

Q 2: Can a planetary concrete mixer handle large aggregates?

A: Yes, a planetary concrete mixer can handle large aggregates. Its robust design and powerful mixing action are suitable for mixes containing larger stone sizes. However, always check the specific model’s maximum aggregate size capacity.

Q 3: What is the typical mixer price range for a high-capacity planetary model?

A: The typical mixer price for a high-capacity planetary model can range significantly. It depends on factors like brand, capacity, and added features. Expect it to be a substantial investment, often starting from tens of thousands of dollars and going much higher.

Q 4: How does a planetary mixer improve mixing uniformity for colored concrete?

A: A planetary mixer improves mixing uniformity for colored concrete through its complex mixing action. This action ensures pigments are dispersed perfectly throughout the mix. This prevents streaks and ensures consistent color in the final product.

Q 5: What are the main points for mixer maintenance on a planetary unit?

A: The main points for mixer maintenance on a planetary unit are thorough cleaning after each use, regular lubrication of the gearbox and moving parts, and frequent inspection of wear parts like paddles and liners. Also, check the shaft seals for any leaks.

Durable Machinery

Durable Machinery