Twin Shaft Concrete Mixer

Charging Capacity:

800-6400L

Discharging Capacity:

500-4000L

A twin shaft concrete mixer is a key part of our product line. It is designed for fast and excellent mixing. This mixer is a type of forced concrete mixer. It uses two horizontal shafts with paddles. These shafts rotate in opposite directions. This action creates a strong mixing effect. It ensures high quality for many types of concrete.

This mixer is known for its speed and ability to handle large volumes. It works well in big construction projects. It is a workhorse in the concrete production line.

Table of Contents

- What Are the Working Principles and Core Advantages of a Twin Shaft Concrete Mixer?

- How Does a Twin Shaft Mixer Ensure High-Speed Mixing and Excellent Uniformity?

- Which Large Concrete Projects or Production Lines Are Best Suited for Twin Shaft Mixers?

- Can a Twin Shaft Mixer Effectively Handle Various Types and Ratios of Concrete?

- What High-Quality or Special Types of Concrete Can It Produce?

- How to Choose the Most Suitable Twin Shaft Mixer Model Based on Your Project Size?

- What Are the Daily Maintenance and Wear Parts Management Points for a Twin Shaft Concrete Mixer?

- FAQs

- Question 5: What are the primary mixer maintenance tasks for this type of mixer?

What Are the Working Principles and Core Advantages of a Twin Shaft Concrete Mixer?

A twin shaft concrete mixer works by using two horizontal mixing shafts. These shafts are placed inside a U-shaped mixing trough. Each shaft has many mixing arms. Paddles are attached to these arms. The two shafts rotate towards each other. This creates a strong mixing zone. This action ensures materials move quickly and thoroughly. This is its core strength.

This design gives it key mixer advantages. It mixes materials fast. It also ensures great concrete mixing uniformity. This makes it a popular choice for many construction jobs.

Understanding the Core Mechanism and Benefits

The twin shaft concrete mixer is a forced concrete mixer. Its working principle is clear. Two horizontal shafts operate in parallel. Each shaft has a series of mixing arms. These arms have replaceable wear-resistant paddles. The shafts rotate in opposite directions. This action creates an intense cross-mixing motion within the trough.

Materials are lifted, dropped, sheared, and tossed around vigorously. This constant intermingling ensures that all components, like cement, aggregates, water, and admixtures, are rapidly and uniformly blended. This method leads to a very short mixing cycle. It also creates a highly homogeneous concrete mix. This is especially important for jobs needing consistent quality.

Key advantages of this system include:

- High Mixing Efficiency: The counter-rotating shafts create a strong mixing action. This quickly breaks up material clumps. It blends everything fast. This means you get a uniform mix in a short time. This boosts productivity for the entire concrete production line.

- Excellent Mixing Uniformity: The cross-mixing motion ensures all particles are thoroughly blended. This reduces segregation. It gives you a consistent product batch after batch. This is vital for high-performance concrete mixing.

- Wide Adaptability: This mixer can handle many types of concrete. It works with common mixes. It also works with mixes that have large aggregates. It handles various slump levels well. This makes it a versatile piece of concrete batching plant equipment.

- Robust and Durable Design: The heavy-duty structure and wear-resistant mixer blades mean it lasts a long time. It can handle continuous, demanding use. This leads to less downtime and lower long-term costs.

- Reliable Operation: Its simple and direct drive system provides dependable performance. It needs minimal complex maintenance.

How Does a Twin Shaft Mixer Ensure High-Speed Mixing and Excellent Uniformity?

A twin shaft mixer ensures both high-speed mixing and excellent uniformity through its specific design. The key is the counter-rotating motion of its two shafts. This motion forces materials to move vigorously. It creates a powerful mixing action. This helps achieve concrete mixing uniformity quickly.

This mixer is built for speed and precision. It combines strong mechanical action with clever material flow. This creates a homogeneous mix fast.

Achieving Optimal Mix Quality Rapidly

The ability of a twin shaft concrete mixer to achieve high efficiency concrete mixing with superior uniformity comes from several design elements:

- Counter-Rotating Shafts: The two horizontal shafts spin in opposite directions. Each shaft has a series of mixing arms with paddles. When these paddles meet, they create a strong cross-mixing zone. This forces all materials to collide and intertwine. This action prevents “dead spots” where materials might not mix well.

- Optimized Paddle Design: The mixing paddles are designed to lift, cut, and fold the material. This ensures every particle moves through the mixing zone. The paddles are also angled to push material towards the center. This intensifies the mixing action.

- High Shear Force: The rapid movement of the paddles creates high shear forces. These forces effectively break up any clumps of cement or fine aggregates. They also help disperse water and admixtures thoroughly throughout the mix. This is crucial for high performance concrete mixing.

- Short Mixing Cycle: The intense mixing action reduces the time needed to achieve a uniform blend. For many standard concrete mixes, a twin shaft concrete mixer can achieve full homogeneity in as little as 30-60 seconds. This short cycle time greatly boosts the overall productivity of the concrete production line.

- Large Mixing Volume: These mixers are often designed for large concrete mixer capacities. They handle big batches efficiently. This makes them ideal for projects needing high volumes of concrete fast.

- Wear-Resistant Components: The mixing paddles and liner plates are made from durable materials. These materials resist wear from abrasive aggregates. This maintains mixing efficiency and uniformity over a long time.

This combination of design features allows the twin shaft concrete mixer to deliver consistent, high-quality concrete at high speeds. It makes it a preferred choice for large-scale operations.

Which Large Concrete Projects or Production Lines Are Best Suited for Twin Shaft Mixers?

A twin shaft concrete mixer is best suited for large concrete projects and high-volume concrete production line setups. Its design helps it produce large amounts of concrete quickly. It also ensures consistent quality. This makes it a top choice for demanding construction tasks.

This mixer provides the speed and reliability needed for continuous concrete supply. It is crucial for keeping big construction jobs on schedule.

Ideal Applications for High-Volume Production

The twin shaft concrete mixer is the workhorse for many large-scale concrete demands:

- Commercial Concrete Batching Plants: These plants produce ready-mix concrete for sale. They need high output and consistent quality. The twin shaft concrete mixer is the standard for these plants. It can rapidly mix various concrete grades. This keeps up with the high demand from construction sites. This is a key part of commercial concrete mixer operations.

- Large Infrastructure Projects:

◦ High-Speed Railways and Highways: These projects need vast amounts of high-quality concrete. They require it delivered on a tight schedule. Twin shaft mixers provide the necessary output.

◦ Dams, Bridges, and Tunnels: These structures demand durable, uniform concrete. They need it in large volumes. The mixer’s ability to ensure consistent quality is vital for structural integrity.

◦ Airports and Port Construction: Paving large areas and building heavy-duty structures require continuous concrete supply. Twin shaft mixers meet this need effectively. - Large Precast Concrete Production Lines: While planetary mixers are great for very specific precast items, twin shaft mixers can handle larger volumes of precast concrete mixing. This is true for standard precast elements like pipes, blocks, and slabs. They produce these at high speed for mass production.

- Centralized Concrete Supply for Large Building Complexes: Big residential or commercial complexes need a steady stream of concrete. A centralized plant with a large concrete mixer ensures this supply.

- Road Construction and Paving: For projects covering large areas, the mixer’s high capacity helps maintain a continuous paving process.

In these environments, the twin shaft concrete mixer’s ability to deliver high output with excellent uniformity is unmatched. It supports efficient and reliable concrete production. This helps keep large-scale projects on time and budget.

Can a Twin Shaft Mixer Effectively Handle Various Types and Ratios of Concrete?

Yes, a twin shaft concrete mixer can effectively handle various types and ratios of concrete. Its robust mixing action is versatile. It can blend a wide range of materials. This makes it suitable for many concrete formulas. It ensures high efficiency concrete mixing for different uses.

The mixer’s strong design allows it to adapt to diverse mix designs. This is true whether you need standard mixes or some specialized concrete.

Versatility in Concrete Mix Designs

The twin shaft concrete mixer is known for its ability to process a broad spectrum of concrete types and ratios.

- Standard Concrete: This includes typical mixes for foundations, slabs, columns, and beams. The mixer achieves fast and uniform blending. This meets common construction needs.

- Dry Hard Concrete: While planetary mixers excel, twin shaft mixers can also handle semi-dry and dry-hard mixes. This is true for products like precast blocks or road pavers. They can achieve adequate compaction and strength.

- High-Strength Concrete: For concrete needing very high compressive strength, the mixer ensures thorough dispersion of cement and admixtures. This helps achieve optimal material interaction and strength development. This is a critical factor for high performance concrete mixing.

- Low Slump Concrete: This mixer efficiently handles mixes with low water content. Its forceful mixing action ensures all particles are coated. This helps achieve good workability even with less water.

- Normal Weight and Lightweight Concrete: It can mix both standard weight concrete with common aggregates. It also mixes lightweight concrete using pumice or expanded clay aggregates.

- Various Aggregate Sizes: The mixer can effectively blend concrete with various aggregate sizes. This ranges from fine sands to larger gravel. Its powerful blades handle different particle sizes well.

- Admixture Integration: It effectively integrates various chemical admixtures. These include water reducers, retarders, and accelerators. It also blends mineral admixtures like fly ash and silica fume. It disperses them evenly throughout the concrete mix.

This versatility makes the twin shaft concrete mixer a valuable asset. It is suitable for many different construction requirements. It can meet diverse project specifications.

What High-Quality or Special Types of Concrete Can It Produce?

A twin shaft concrete mixer can produce a range of high-quality and special concrete types. Its design for fast and powerful mixing helps create consistent mixes. This is true even for more demanding formulas. While some very specialized mixes might prefer a planetary mixer, the twin shaft performs excellently for many. It ensures high performance concrete mixing for various applications.

This mixer is a strong choice when you need both volume and quality. It can meet the needs of many modern construction requirements.

Producing Advanced Concrete Solutions

The twin shaft concrete mixer can produce these high-quality or special types of concrete:

- High-Strength Concrete: This concrete has increased compressive strength. The mixer ensures excellent dispersion of cement and admixtures. This leads to a denser, more consistent mix. This helps achieve the required strength.

- Self-Compacting Concrete (SCC): SCC flows and compacts under its own weight. The mixer ensures that superplasticizers are thoroughly dispersed. This gives the concrete the needed fluidity without segregation.

- Roller-Compacted Concrete (RCC): RCC is a very stiff concrete. It is often used for pavements and dams. The mixer’s powerful action can handle the low water content. It creates a homogeneous mix suitable for roller compaction.

- Fiber-Reinforced Concrete: This concrete has fibers (steel, synthetic, glass) to improve its tensile strength and crack resistance. The twin shaft mixer can effectively disperse these fibers. It prevents clumping. This ensures the fibers are evenly distributed for maximum reinforcement.

- Mass Concrete: Used in large structures like dams and foundations. The mixer can produce large volumes of uniform concrete. This is crucial for managing hydration heat and preventing cracking.

- Colored Concrete: For architectural concrete, the mixer ensures pigments are evenly dispersed. This achieves consistent color throughout the batch. It avoids streaking.

- Waterproof/Permeable Concrete: Depending on the specific mix design, the mixer can help produce concrete with reduced permeability. It can also produce concrete designed to allow water to pass through.

- Pumpable Concrete: The mixer produces a consistent, workable mix. This is essential for concrete that needs to be pumped long distances or to high elevations. Its uniformity reduces blockages in the pump.

The ability to produce these specialized concretes makes the twin shaft concrete mixer a versatile investment. It meets diverse project specifications.

How to Choose the Most Suitable Twin Shaft Mixer Model Based on Your Project Size?

Choosing the most suitable twin shaft mixer model depends heavily on your project size. This means matching the mixer’s mixer capacity to your specific concrete demand. The right choice ensures efficient production. It also prevents bottlenecks.

Selecting the correct model helps maximize output. It minimizes operational costs for your concrete production line. This ensures your project stays on track.

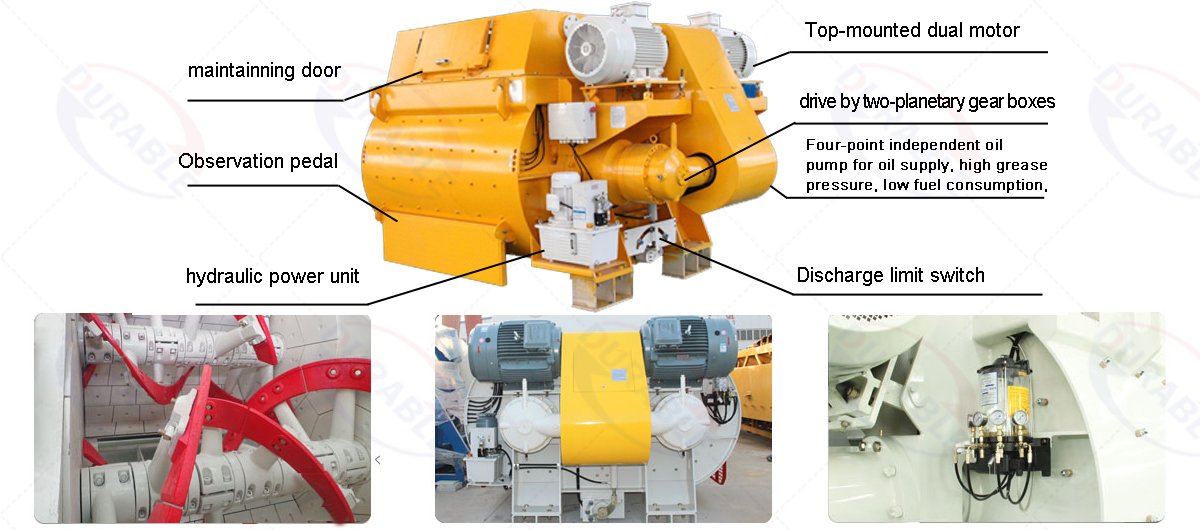

Technical Parameters

| Model | JS/JSS500 | JS/JSS750 | JS/JSS1000 | JS/JSS1500 | JS/JSS2000 | JS/JSS3000 | JS/JSS4000 |

| Charging Capacity | 800L | 1200L | 1600L | 2400L | 3200L | 4800L | 6400L |

| Discharging Capacity | 500L | 750L | 1000L | 1500L | 2000L | 3000L | 4000L |

| Productivity | 25m³/h | 35m³/h | 50/60m³/h | 75/90m³/h | 120m³/h | 180m³/h | 240m³/h |

| Aggregate Size | 80/60 | 80/60 | 80/60 | 80/60 | 80/60 | 120/100 | 120/100 |

| Mixing Power | 18.5kw | 30kw | 2*18.5kw | 2*22kw | 2*37kw | 2*55kw | 2*75kw |

| Lifting Motor | 5.5kw | 7.5kw | 11kw | 18.5kw | – | – | – |

| Discharging Mode | Manual/Pneumatic/Hydraulic | Pneumatic/Hydraulic | Hydraulic | ||||

| Lubrication Mode | Manual | Manual/Automatic | Automatic | Automatic | Automatic | Automatic | |

| Overall Dimension | 4486x3030x5280 | 5100x2250x6700 | 5100x2250x6700 | 3600x2070x1475 | 3500x2320x1677 | 3990x2600x1700 | 4450x3050x2380 |

| Weight | 3970kg | 6100kg | 8500kg | 9200kg | 10100kg | 13500kg | 15000kg |

Matching Mixer to Project Scale

When selecting a twin shaft concrete mixer model, consider these factors related to your project size:

- Required Concrete Output:

◦ Peak Demand: What is the maximum amount of concrete you need per hour or per day? This is the most crucial factor. Our mixers come in various capacities, from small models for intermittent use to large concrete mixer units for continuous high-volume production.

◦ Project Duration: For long-term projects, invest in a mixer that can sustain continuous operation without strain. - Batching Plant Type:

◦ Mobile Batching Plants: For temporary or frequently moving projects, match the mixer to the mobile plant’s design. Our mobile batching plants often use twin shaft mixers for their efficiency.

◦ Fixed Batching Plants: For permanent concrete production lines, you have more flexibility in mixer size. Choose one that integrates seamlessly with your overall plant layout. - Type of Concrete Being Produced: While twin shaft mixers are versatile, consider if you will mostly produce standard concrete or if high performance concrete mixing for specialty mixes is required. This influences necessary features like mixing power and wear parts.

- Site Constraints:

◦ Space: Ensure the chosen mixer fits within your available footprint. Twin shaft mixers typically have a horizontal layout.

◦ Foundation: Larger mixers require stronger foundations. - Budget and Cost-Effectiveness:

◦ Initial Investment: Bigger mixers cost more upfront.

◦ Operational Costs: Consider power consumption, wear part replacement frequency, and labor needs for different sizes. Sometimes, two smaller mixers might offer more flexibility than one very large one, depending on production fluctuations. - Future Expansion: If you anticipate growing demand, choose a mixer that offers some room for increased capacity. Or, plan for easy addition of another mixer later.

Our expert team can help you analyze your project’s specific needs. We will recommend the optimal twin shaft concrete mixer model. We ensure it balances capacity, performance, and cost-efficiency.

What Are the Daily Maintenance and Wear Parts Management Points for a Twin Shaft Concrete Mixer?

Daily maintenance is vital for a twin shaft concrete mixer. It ensures smooth operation. It also extends its service life. Proper management of wear parts is also crucial. It helps maintain mixing uniformity and prevents costly downtime.

These actions keep your mixer running efficiently. They protect your investment in concrete production line equipment.

Essential Care for Mixer Longevity

To ensure your twin shaft concrete mixer performs reliably, follow these maintenance and wear parts management points:

- Daily Cleaning (Critical): This is the most important step. Clean the mixing drum and paddles thoroughly after each shift. Hardened concrete buildup reduces mixing efficiency. It also increases wear. Use high-pressure water, scrapers, or the mixer’s automated cleaning system if available.

- Lubrication Check: Ensure all bearings and gears are properly lubricated. Check grease points for the shaft ends and gearbox. Refill lubricants as needed according to the manufacturer’s schedule. Proper lubrication prevents premature wear of critical components.

- Wear Parts Inspection:

◦ Mixing Paddles: Inspect the wear-resistant mixer blades daily for wear and tear. Worn paddles reduce mixing efficiency and can damage the mixer. Replace them promptly when wear exceeds acceptable limits.

◦ Liner Plates: Check the wear-resistant liner plates inside the mixing trough. Replace them if they show significant thinning or damage. This protects the main trough from wear.

◦ Scrapers: Ensure any scrapers are intact and properly adjusted. They keep the walls clean. - Shaft End Seal Check: Inspect the shaft end seals for any signs of slurry leakage. Leaks can damage the gearbox bearings. Address any leaks immediately. This is a key part of mixer maintenance.

- Bolt Tightness: Check all bolted connections, especially on the mixing arms and paddles. Ensure they are tight. Loose bolts can lead to vibrations and premature wear.

- Discharge Gate Operation: Test the discharge gate. Ensure it opens and closes smoothly without obstruction. Clear any material buildup around the gate.

- Motor and Reducer Noise: Listen for any unusual noises from the motor or reducer. Strange sounds can signal a problem needing inspection.

- Electrical System Check: Inspect electrical cables and control panel. Look for damage or loose connections. Ensure emergency stop buttons work correctly.

- Weekly/Monthly Checks: Perform more detailed checks weekly or monthly. This includes checking belt tension, oil levels, and filter conditions in the hydraulic system (if applicable).

By following these routine checks and proactive replacements, you can extend the life of your twin shaft concrete mixer. You can also ensure its consistent performance. This reduces operating costs.

FAQs

Q 1: What makes a twin shaft concrete mixer ideal for large concrete projects?

A: A twin shaft concrete mixer is ideal for large concrete projects because it offers high output capacity and rapid mixing. It consistently produces uniform concrete in large volumes. This helps meet tight project schedules and demands.

Question 2: How often should wear-resistant mixer blades be replaced?

A: The replacement frequency for wear-resistant mixer blades depends on the abrasiveness of your aggregates and mixing volume. Daily inspection is needed. Blades usually need replacement every few months to a year. This ensures optimal concrete mixing uniformity.

Question 3: Is a twin shaft concrete mixer suitable for high performance concrete mixing?

A: Yes, a twin shaft concrete mixer is very suitable for high performance concrete mixing. Its strong shear forces and thorough blending action ensure admixtures and fine materials are fully dispersed. This helps achieve high strength and consistency.

Question 4: How does a twin shaft mixer fit into a concrete production line?

A: A twin shaft mixer fits into a concrete production line as the central mixing unit. It receives materials from batching hoppers. It then discharges mixed concrete into a truck or conveyor for transport. It is the heart of the plant.

Question 5: What are the primary mixer maintenance tasks for this type of mixer?

A: The primary mixer maintenance tasks for a twin shaft mixer include daily cleaning of the mixing drum and paddles, regular lubrication of bearings and gearbox, and frequent inspection and timely replacement of wear-resistant mixer bladesand liner plates.

Durable Machinery

Durable Machinery