Concrete Mixer Truck

Mixing capacity(m³):

3-14

Available chassis:

HOWO/FOTON/SHACMAN

Application:

Concrete mixer trucks (or transit mixers) are vital for maintaining concrete consistency and preventing setting during transport, ensuring high-quality delivery to construction sites. Their extensive applications cover virtually all construction and infrastructure projects requiring large volumes of concrete, including: Large-scale Infrastructure Development, Civil and Commercial Buildings, Industrial Plants and Facilities, Municipal and Rural Construction, and Special Projects and Temporary Applications.

As a specialist in heavy machinery, I know the crucial role a concrete mixer truck plays. This vehicle is vital for delivering ready-mix concrete. It ensures concrete reaches construction sites fresh and ready. It also maintains concrete quality during transport. This makes it a core asset for modern construction. Choosing the right one can directly impact your project’s success and your investment return.

Table of Contents

What is a Concrete Mixer Truck?

A concrete mixer truck, often called a concrete agitator truck or simply a mixer truck, is a special vehicle. It carries ready-mixed concrete from a batching plant to a construction site. Its main job is to keep the concrete in a liquid state. It also prevents the concrete from hardening or separating during travel. This ensures the concrete arrives at the site with the correct quality for use.

This truck is more than just a transporter. It is a mobile mixing unit. Its drum continuously rotates. This motion makes sure the concrete stays consistent. This is vital for any large construction project. It helps maintain the strength and finish of the final concrete structure.

How it Works to Deliver Concrete

The process starts at a concrete batching plant. Freshly mixed concrete loads into the mixer truck’s rotating drum. The drum starts spinning at a slow speed. This gentle rotation prevents the concrete from settling. It also keeps the mix uniform throughout the journey. This part of the process is known as ready mix concrete transport.

Once the truck reaches the construction site, the drum changes direction. It spins faster to push the concrete out. The concrete comes out through a discharge chute. This chute can move and extend. It allows for precise placement of the concrete. After unloading, the drum gets flushed with water. This cleaning step prevents old concrete from hardening inside.

| Step | Action | Purpose | Your Benefit |

|---|---|---|---|

| Loading | Concrete poured into drum at plant | Fill the truck with fresh mix | Quick and efficient pick-up |

| Transport/Mix | Drum rotates slowly during travel | Prevent hardening and segregation | Consistent concrete quality on arrival |

| Discharge | Drum reverses, concrete flows out | Deliver concrete to exact spot | Precise placement, reduced labor |

| Cleaning | Water flushes drum and chute | Remove residue, maintain drum | Prolong equipment life, prevent costly damage |

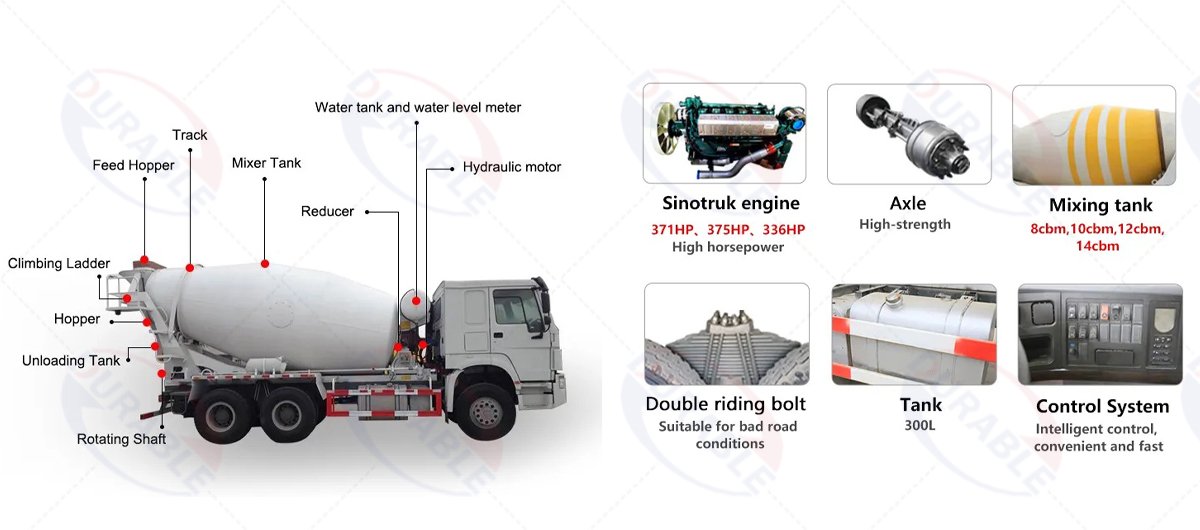

What Core Technologies Power Our Concrete Mixer Trucks?

Our concrete mixer trucks use advanced technology and robust design. We build them for demanding jobs. Our experience in heavy machinery means we focus on durability and performance. This ensures our trucks deliver concrete reliably.

We pay close attention to every detail. This includes the chassis, the engine, and the mixing drum. We also focus on the hydraulic system. This commitment to quality makes our trucks stand out. They offer consistent performance for your construction projects.

Strong Foundations: Chassis and Engine

Our mixer trucks start with a very strong base. We use heavy-duty chassis from top brands. These brands include Sinotruk, Foton, Shacman, and Dongfeng. We also use global brands like Mercedes-Benz and Volvo. These chassis have high load capacity. They feature strong frames. This helps them handle heavy loads. They work well on various road conditions.

We fit our trucks with powerful and efficient engines. These are from trusted brands like Cummins and Weichai. These engines meet the latest emission standards. They offer strong power. They are also fuel-efficient. This means they can run for long hours. They handle tough work easily. We also match them with professional gearboxes. This ensures good pulling power, speed, and climbing ability.

Precision Mixing: Drum and Hydraulics

The mixing drum and spiral blades are critical. We make them from high-strength, wear-resistant steel. We use materials like Q345B/C steel. We also use manganese steel or wear-resistant alloy steel. This design ensures the concrete mixes evenly. It also speeds up discharge. Very little concrete is left behind. This means a longer working life. Our long experience with mining equipment wear parts helps us here.

We use hydraulic systems from top international brands. These include Rexroth, Eaton, PMP, and Sauer-Danfoss. These systems drive the mixing drum. They ensure smooth and precise rotation. They are highly efficient. They also have low failure rates. Our trucks feature easy-to-use control levers. These let operators precisely control the drum speed and direction. This makes mixing, transport, and discharge very accurate.

Safety and Smart Features

Our trucks come with comfortable and safe cabs. They are wide. They offer great visibility. Their design reduces driver tiredness. This makes long shifts easier. We also include many safety features. These are strong brake systems, backup cameras, and safety ladders. There are also emergency stop buttons. All these ensure safe driving and operation.

We offer smart auxiliary systems too. These are optional. You can add GPS tracking. You can add a weighing system. You can also monitor drum speed and concrete temperature. Remote fault diagnosis is also possible. These features improve truck management. They also make operations more efficient.

| Component Group | Key Features | Your Direct Benefit |

|---|---|---|

| Chassis/Power | Heavy-duty, high-strength frame, efficient engine | Handles heavy loads, reliable on tough roads, saves fuel |

| Mixing System | Wear-resistant drum, precise hydraulic system | Consistent concrete quality, fast discharge, long life |

| Safety/Smart | Comfortable cab, many safety features, optional smart tech | Safe operation, reduced fatigue, better management |

Which Projects Benefit Most from a Concrete Mixer Truck?

A concrete mixer truck is essential for projects that need a lot of concrete. It is especially useful when the concrete needs to be delivered continuously. Its main job is to transport ready mix concrete transport from a central plant to the construction site. This ensures a steady and high-quality concrete supply.

These trucks are perfect for large buildings. They are also vital for new roads, bridges, and tunnels. Any project that uses a large amount of pre-mixed concrete benefits greatly. They help keep projects on schedule. They also ensure the quality of the concrete pouring.

Ideal Scenarios for Concrete Delivery

Concrete mixer trucks are a core asset for several types of businesses. The biggest users are concrete producers and ready-mix concrete companies. These businesses rely on our trucks to deliver their products to various construction sites. These sites include residential buildings, commercial complexes, and industrial plants.

Large construction companies and contractors also buy or lease these trucks. They use them for their own big projects. This helps them meet high concrete demands. Infrastructure construction companies use them for roads, railways, bridges, and tunnels. These projects need huge amounts of continuous concrete supply. Our trucks are essential tools for these jobs. Mining companies sometimes need large concrete pours for new structures or equipment foundations. Our trucks can fulfill these mining concrete equipment needs. Rental companies also find these trucks popular. They offer stable rental demand. This gives them good investment returns.

How Do You Choose the Right Concrete Mixer Truck?

Choosing the best concrete mixer truck needs careful thought. You must match the truck’s features with your project’s demands. This ensures you get the best value for your money. It also helps your operations run smoothly.

First, think about the amount of concrete you need to move. Then, consider the roads your trucks will travel. Finally, evaluate the specific site conditions. These factors will guide you to the perfect mixer truck for your business.

Technical Parameters

| Model | CMT-3 | CMT-4 | CMT-5 | CMT-6 |

| Mixing Capacity (m3) | 3 | 4 | 5 | 6 |

| Charging Speed ( m3/min) | ≥ 2.5 | ≥ 2.5 | ≥ 2.5 | ≥ 2.5 |

| Discharging Speed ( m3/min) | ≥ 1.5 | ≥ 1.5 | ≥ 1.5 | ≥ 1.5 |

| Water Tank Capacity (L) | 150 | 150 | 200 | 200 |

| Mixing Tank Material | 16Mn-Alloy Steel | 16Mn-Alloy Steel | 16Mn-Alloy Steel | 16Mn-Alloy Steel |

| Tank Body Thickness (mm) | 5 | 5 | 5 | 5 |

| Head Thickness (mm) | 6 | 6 | 6 | 6 |

| Hydraulic Pump | Sunny-USA / Eaton- USA /PMP- Italy | Sunny-USA / Eaton- USA /PMP- Italy | Sunny-USA / Eaton- USA /PMP- Italy | Sunny-USA / Eaton- USA /PMP- Italy |

| Hydraulic Motor | Sunny-USA/ Eaton- USA /PMP- Italy | Sunny-USA / Eaton- USA /PMP- Italy | Sunny-USA/ Eaton- USA /PMP- Italy | Sunny-USA/ Eaton- USA /PMP- Italy |

| Reducer | ZF Brand-Germany /Bonfiglioli- Italy /PMP- Italy | ZF Brand-Germany /Bonfiglioli- Italy /PMP- Italy | ZF Brand-Germany /Bonfiglioli- Italy /PMP- Italy | ZF Brand-Germany /Bonfiglioli- Italy /PMP- Italy |

| Radiator (L) | 12 | 12 | 12 | 12 |

| Available Chassis | HOWO/FOTON/ SHACMAN | |||

| Model | CMT-8 | CMT-10 | CMT-12 | CMT-14 |

| Mixing Capacity (m3) | 8 | 10 | 12 | 14 |

| Charging Speed (m3/min) | ≥3 | ≥3 | ≥3 | ≥3 |

| Discharging Speed (m3/min) | ≥2 | ≥2 | ≥2 | ≥2 |

| Water Tank Capacity (L) | 450 | 450 | 450 | 450 |

| Mixing Tank Material | 16Mn-Alloy Steel | 16Mn-Alloy Steel | 16Mn-Alloy Steel | 16Mn-Alloy Steel |

| Tank Body Thickness (mm) | 5 | 5 | 5 | 5 |

| Head Thickness (mm) | 6 | 6 | 6 | 6 |

| Hydraulic Pump | Sunny-USA / Eaton- USA /PMP- Italy | Sunny-USA / Eaton- USA /PMP- Italy | Sunny-USA / Eaton- USA /PMP- Italy | Sunny-USA / Eaton- USA /PMP- Italy |

| Hydraulic Motor | Sunny-USA/ Eaton- USA /PMP- Italy | Sunny-USA/ Eaton- USA /PMP- Italy | Sunny-USA/ Eaton- USA /PMP- Italy | Sunny-USA/ Eaton- USA /PMP- Italy |

| Reducer | ZF Brand-Germany /Bonfiglioli- Italy/PMP- Italy | ZF Brand-Germany /Bonfiglioli- Italy /PMP- Italy | ZF Brand-Germany /Bonfiglioli- Italy /PMP- Italy | ZF Brand-Germany /Bonfiglioli- Italy /PMP- Italy |

| Radiator (L) | 18 | 18 | 18 | 18 |

| Available Chassis | HOWO/FOTON/ SHACMAN | |||

Key Selection Factors

When choosing a mixer truck, its capacity is very important. Truck drums come in different sizes. They range from 6 cubic meters to 12 cubic meters, or even larger. You must match the drum size to your project’s concrete needs. For example, smaller projects might use 6-8 cubic meter trucks. Larger projects often need 10-12 cubic meter trucks. This choice impacts how many trips are needed. It also affects overall engineering efficiency.

Next, look at the truck’s chassis and engine power. A stronger engine is better for long distances or hilly roads. The chassis must handle heavy loads safely. Consider the hydraulic system. A high-quality hydraulic system ensures the mixing drum rotates smoothly. It also provides reliable discharge. Pay attention to the mixing drum design. A good design prevents concrete anti-segregation. This keeps concrete quality high. Check for safety features. Also, consider smart systems like GPS. These help with fleet management. They improve overall concrete delivery.

What is the Real Cost and ROI of a Mixer Truck?

Investing in a concrete mixer truck involves more than just the purchase price. You need to look at its full lifecycle costs. This includes initial cost, running costs, and maintenance. Understanding these factors helps you calculate the true return on investment (ROI). A well-chosen truck can save you money in the long run. It can also boost your profits significantly.

The immediate savings come from reliable concrete delivery. It also comes from reduced operational risks. Over time, its efficiency and durability contribute to a faster payback. This makes it a smart asset for any business in ready mix concrete transport.

Understanding Operating Costs

The operating cost of a mixer truck includes several key elements. Fuel consumption is a major part. Modern trucks with efficient engines help lower this. Tire wear is another factor. This is especially true for trucks that travel on rough roads. Regular maintenance is also important. This includes oil changes, filter replacements, and checking hydraulic systems. Preventative maintenance can save you from big repair bills later.

Labor costs for drivers also add up. Efficient route planning can reduce driver hours. Insurance, registration, and depreciation are also part of the total cost. Consider the cost of water for cleaning the drum. Minimizing concrete waste also reduces costs. A well-managed truck fleet can significantly lower these expenses. This boosts your profitability.

Calculating Your Return

The ROI of a concrete mixer truck comes from direct and indirect benefits. Directly, you save money by ensuring timely concrete delivery. You avoid delays that cost money. You also ensure high concrete quality. This reduces rework and material waste. These savings quickly add up.

Indirectly, owning your trucks gives you control. You are not dependent on third-party transport. This improves project scheduling. It also increases your business flexibility. A reliable fleet means you can take on more projects. This increases your revenue. The efficient use of our trucks can lead to a payback period of just a few years. This makes the investment highly profitable over the truck’s long service life.

Why Choose Durable for Your Concrete Mixer Truck?

Choosing Durable for your concrete mixer truck means choosing a partner with deep industry knowledge. We are a Chinese manufacturer, Durable Machine Co., Ltd., founded in 2001. We bring years of experience in heavy machinery. This includes both mineral processing and construction equipment. Our focus is on providing reliable and efficient solutions.

We understand the needs of B2B clients. We know you require tough, effective machines. We also know you need strong support. Our commitment to quality and service sets us apart. This makes us a strong choice for your next mixer truckpurchase.

Our Expertise and Quality

We use our extensive experience in heavy machinery manufacturing. We build concrete mixer trucks that are robust and dependable. We apply the same strict quality controls from our mining equipment line to our mixer trucks. This means durable components and reliable performance. Our manufacturing includes advanced robot welding for strong, consistent seams. We also use laser cutting for precise parts. These methods ensure high quality and fit.

We select key components carefully. Our engines and hydraulic systems come from world-renowned brands. This ensures high reliability and a long service life for your truck. Every truck undergoes strict quality checks. This includes checks on raw materials, during production, and final performance tests. This dedication ensures your truck is built to last. It handles the toughest jobs with ease.

Comprehensive Support

We offer more than just selling you a truck. We provide a full solution. This starts with professional advice. We help you choose the right truck for your project. We consider your project scale, transport distance, and site conditions. Our global experience means we understand different regulations. This ensures your equipment works legally and efficiently anywhere.

We provide full project support. This covers manufacturing, quality testing, and global shipping. We also offer initial setup and training. Our dedicated after-sales service team is ready to help. We offer 24/7 technical support. We also have a global spare parts network. This reduces downtime. It helps keep your projects on schedule. Our focus is on making your operations as smooth and profitable as possible.

| Durable Advantage | Your Direct Benefit |

|---|---|

| Robust Construction | Less downtime, longer equipment life |

| Premium Components | Higher reliability, lower maintenance |

| Precise Manufacturing | Consistent performance, high concrete quality |

| Global Experience | Compliance with international standards, smooth import |

| Full Support | Expert guidance, fast troubleshooting, reliable parts |

FAQs

Q1: What is the average mixer truck capacity for typical construction projects?

A: The average mixer truck capacity for most projects ranges from 8 to 12 cubic meters. Smaller projects might use 6 cubic meters. Very large projects sometimes use trucks over 12 cubic meters. The best capacity depends on your specific project needs.

Q2: How important is concrete anti-segregation in a mixer truck?

A:Concrete anti-segregation is very important. It means the concrete stays mixed and consistent. A good mixing drum design prevents heavy parts from settling. It ensures the concrete poured at the site has the right strength and quality.

Q3: What role does the hydraulic system play in a mixer truck?

A:The hydraulic system powers the mixing drum’s rotation. It ensures smooth and precise control of the drum. This is vital for proper mixing during transport. It is also key for efficient and controlled discharge of concrete at the site.

Q4: Can a mixer truck reduce my operating cost?

A:Yes, a mixer truck can reduce your operating cost. Owning your trucks saves you from third-party delivery fees. It also gives you better control over scheduling. This can lead to more efficient work. Over time, these savings add up significantly.

Q5: What should I look for in a good mixer truck brand?

A:When looking for a mixer truck brand, focus on reliability and durability. Check for strong chassis and high-quality components. Look for good after-sales support and spare parts availability. A trusted brand will offer long-term value and fewer breakdowns.

Durable Machinery

Durable Machinery